Sponsored by PerkinElmerReviewed by Olivia FrostMar 28 2024

Calibration plays a crucial role when it comes to ensuring the effectiveness and efficiency of testing instruments in aiding the production of dairy products.

While these testing tools are essential for verifying the quality and makeup of ingredients and final products, it is vital for processors to perform instrument calibration consistently. This practice is key in sustaining operational productivity and averting potential financial and product losses.

Image Credit: PerkinElmer

"Calibration is a fundamental requirement for even the most advanced instruments and software," explains Jackie Trudell, senior global market manager for dairy and liquids at PerkinElmer. "Regular and precise calibration of an analyzer is essential to sustain its ability to consistently deliver accurate and reliable results."

The importance of calibration in dairy production cannot be overstated. It is the linchpin supporting product quality, customer satisfaction, and operational efficiency.

Therefore, it remains an essential requirement for processors to ensure their products consistently adhere to necessary standards and consumer expectations, safeguarding their reputation and success in the market.

The significance of accuracy in measuring raw milk composition during intake extends beyond quality control; it holds notable implications for the relationship between processors and farmers.

Processors depend on precise measurements of key milk components, including fat, protein, moisture, carbohydrates, solids, and lactose, to determine fair compensation for farmers. This ensures farmers receive equitable payment based on the quality and composition of the provided milk.

The commitment to accuracy ultimately contributes to maintaining stability and sustainability in the dairy supply chain, benefiting processors and farmers. For processors, precision in measuring elements is crucial to meeting the necessary product parameters.

From Accuracy to Efficiency

Image Credit: PerkinElmer

Precision in calculating elements is crucial for meeting contractual obligations but also for minimizing waste and maximizing profits.

The production of various milk varieties raises concerns about potential product waste, often involving the removal of all fat from raw milk before adding back the necessary amount to achieve the desired product fat content.

“To confirm that their process is correct and finished products meet the necessary standards, processors will test products to verify the proximate values, including fat, protein, lactose, total solids, and solids that are not fat,” Trudell explains.

“If a milk item is being analyzed for fat content and the predicted result is 2 percent, it should be near 2 percent fat when using reference methods. If the sample contained 3 percent fat, there would be an additional 1 percent in the product which could have been used for manufacturing other products.”

Such inaccuracies can also lead to regulatory problems, particularly in the production of butter, which typically requires at least 80 percent fat, depending on the country of production.

“If the instrument is not accurately quantifying fat content because it was not calibrated and it is reading 80 percent fat, but the amount is actually 78 percent, the organization can get into a lot of trouble because they are now selling something that isn’t butter,” Trudell says.

“On the flip side, if the instrument is showing 80 percent but it is 82, percent, they are giving away 2 percent of the fat that they could be using elsewhere. It can impact margins long term if the readings are inaccurate.”

Operators can assess the need for calibration by regularly running standards or test samples with known results through inspection instruments, and carefully analyzing the data obtained.

“Over time there will be a drift and that is a trigger for performing a calibration and adjusting the instrument back to where it should be,” says Sofia Karlberg, global product manager at PerkinElmer.

PerkinElmer's most versatile mid-infrared analyzer, the LactoScope™FT-A, accurately tests a broad spectrum of dairy products, including milk, creams, whey, concentrates, ice creams, and yogurt mixes in just 30 seconds.

The calibration frequency of testing instruments aligns with the volume of samples processed. An extensively used instrument analyzing hundreds of samples daily may require recalibration every four weeks, whereas a sparingly used device can remain stable for 12 weeks or even longer.

“Running large amounts of samples will cause the equipment to drift faster and differences in the results will occur faster,” Karlberg says. “Then, there is a need to calibrate the instrument more often to bring it back to the true reading.”

The nature of the product being processed also affects calibration frequency, with products containing particles, like sugar, causing increased equipment wear. Processors dealing with sugar-rich products like chocolate milk and fruit-flavored yogurt may need more frequent instrument calibrations than those exclusively handling raw milk.

Larger processors face substantial consequences if they use analyzers that provide less accurate results. Such companies may lose massive amounts of product, money, and prestige if performance is off even slightly.

For instance, processors producing millions of pounds of butter annually risk significant waste if finished products contain 81 percent fat instead of the required 80 percent.

Precision underscores the growing importance of effectively leveraging reference samples. While processors can create reference samples, purchasing from external providers ensures accurate composition.

Reference samples are available for each product type—raw milk, processed milk, cream, and whey—and the quantity sought by processors varies based on the diversity of products their plants produce.

Milk producers alone may routinely utilize up to half a dozen reference sample types to match different fat levels in their items.

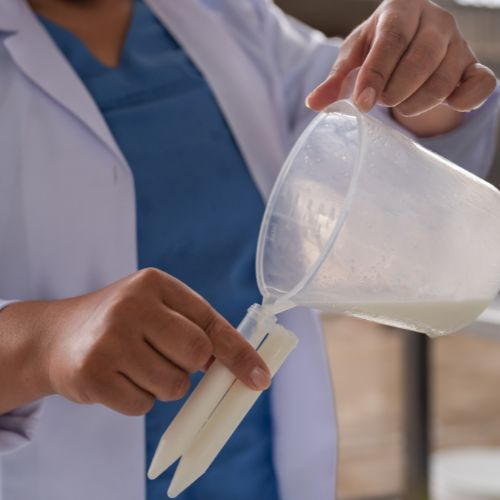

Dairy Sample Expertise for Calibration

Image Credit: PerkinElmer

Accurate calibration of testing devices requires essential training from experts, many of whom are affiliated with instrument manufacturers and reference sample providers. Learning to handle and maintain test samples is a critical aspect in this regard.

“It is not difficult to run the samples, which almost anyone can do,” Karlberg says. “It is more of how to treat and properly store the samples.”

Samples, available in fresh and frozen states, need to be stored in suitable refrigerators or freezers to maintain their effectiveness. Before use, samples should be warmed in a water bath at approximately 104 degrees Fahrenheit (40 degrees Celsius) and thoroughly mixed or turned to ensure homogeneous composition.

When evaluating testing equipment accuracy, processors typically run five samples through the instruments before and after calibration adjustments.

“There will be differences between the sample test results and the actual composition of the product if the calibration has not been done correctly,” Karlberg says.

Calibrating the device can take two or more hours, with longer durations for facilities producing a diverse range of dairy products.

It is important for workers to closely adhere to the instrument manufacturer’s specifications to achieve precise readings, and calibration should occur under suitable plant conditions, including maintaining proper temperatures.

Technology suppliers contribute to calibration initiatives by providing software that facilitates easy adjustment of equipment settings based on the results of reference sample analyses.

“After running the reference samples, users can enter the lab results into the software and it will calculate the recommended adjustment to the instrument,” Karlberg states.

“The Results Plus software that we use in conjunction with the LactoScope FT-A is designed to guide the user to make a correct adjustment to the instrument. This can also be done remotely by using a cloud solution like our NetPlus™software.”

Consider the Options

Image Credit: PerkinElmer

While many operators choose to internally calibrate equipment, companies can delegate the process to third parties.

Outsourcing can alleviate processors of the time and expense associated with having in-house workers perform the measures, allowing them to focus on other priorities. However, the external organization must possess the necessary accreditations and certifications to provide these services.

Whether the calibration is conducted internally or by a third party, it can incur significant costs, especially considering the expense of purchasing samples, which can amount to hundreds of dollars. Many companies opt for a subscription model for reference standards, receiving samples every two months.

“Processors with sophisticated laboratories can develop their own reference methods and standards,” Karlberg says. “But when you buy the samples externally, you know that the results they come with are accurate. In most cases, it is better to source them externally.”

Nevertheless, there are situations where operators may need to create their samples, especially when vendors lack references for products with proprietary recipes and uncommon compositions.

Dairy producers should analyze and adjust devices at scheduled intervals for optimal calibration. Affixing an approved identification mark to devices post-calibration confirms the procedure was completed.

“It is important that processors take ongoing steps to ensure that their instruments remain top of the line and calibration is a very important part of that,” Trudell states. “Similar to the need for ongoing automobile maintenance, routine upkeep of the testing analyzers is crucial to keep them running smoothly.”

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.