The electrical industry is one of the numerous sectors participating in the development of sustainable energy practices. Green transformers are efficient contemporary solutions for electricity transmission and distribution, as well as the modernization of the power grid.

Image Credit: Saint-Gobain

As well as reducing carbon dioxide (CO2) emissions and enhancing energy efficiency, green transformers have improved life cycle and fire safety, and require less maintenance.

The demand for green power transformers is, therefore, growing, with the market size projected to increase more than 6.5% from 2023 to 2032. This growth is supported by the expansion of renewable energy projects and the increasing demand to decrease energy losses during power transmission and distribution.

To ensure the longevity and performance of these green transformers, design engineers must choose materials that can endure the most demanding applications, have excellent mechanical and thermal resistance, and have high chemical compatibility.

Safer Energy Distribution and Environmental Superiority

The base materials within green transformers come from bio-based ester oils, which have greater fire retardance. In contrast to mineral oil alternatives, ester oils exhibit a higher fire point, surpassing 300 °C, compared to the 170 °C of mineral oil. These fire safety advantages enable green transformers to run at increased temperatures, allowing for amplified power distribution.

Green transformers are designed for more energy-efficient operations to minimize power loss. It is also unnecessary to expand the transformer unit's size and weight.

Ester oil transformers can be compact and provide power output comparable to mineral transformers, saving space. Compared to mineral oils, ester fluids are reported to perform better and be environmentally superior (as they are biodegradable and non-toxic).

In the event of an oil spill, these oils rapidly break down, mitigating environmental risks. This makes spill mitigation, clean-up, and recycling processes more straightforward and less expensive.

Utilizing bio-based materials also facilitates a longer equipment lifecycle. Ester oil demonstrates greater resistance to oxidation and oxidative generation compared to mineral oils. They also have a higher water saturation limit and can dry out moisture content from cellulose paper ten times quicker than mineral oils. This safeguards them from transformer failure by protecting the cellulose insulation. Esters also withstand more moisture without degrading dielectric properties.

With a smaller size, limited pollution risk, increased efficiency, reduced maintenance expenses, an optimized lifecycle, and greater safety due to less flammability, green transformers are a solid, more sustainable alternative to conventional transformers.

Common Challenges and How to Mitigate Them to Optimize Performance

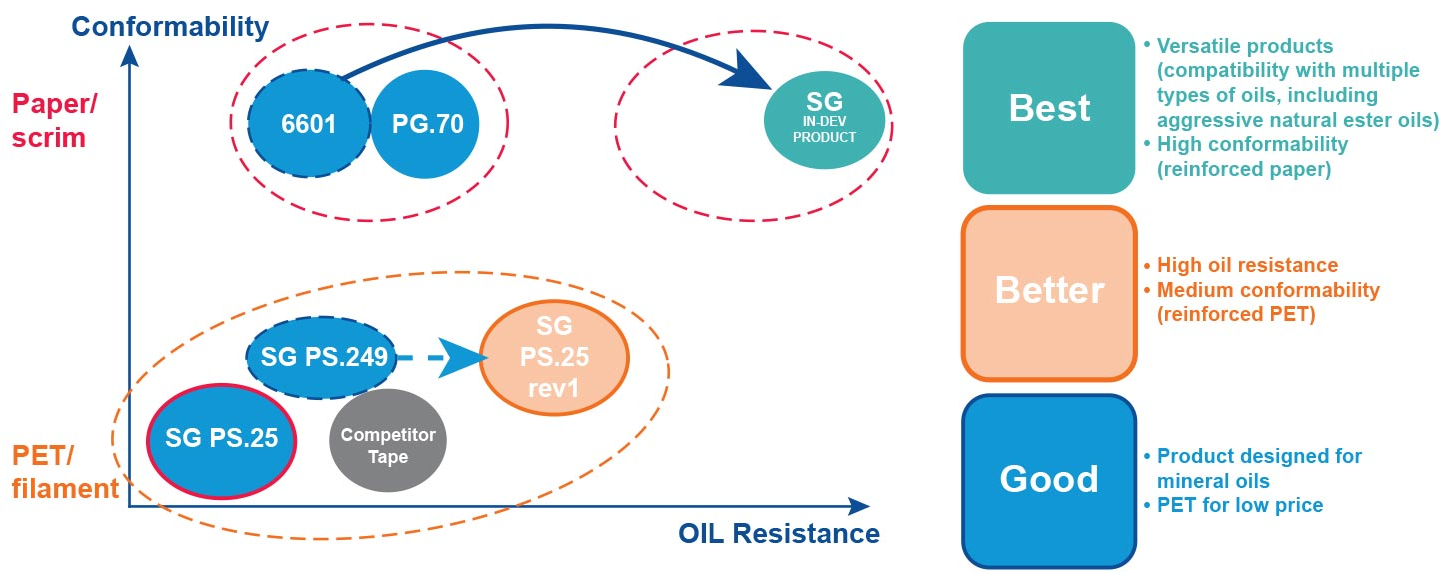

Saint-Gobain® Tape Solutions offers an extensive range of adhesive tapes, renowned for their chemical stability, long-term thermal capability, and superior adhesion. Variations in the formulations of acrylic adhesives help design engineers accomplish improved chemical compatibility with transformer oils.

When choosing products for green transformers, it is important to note that ester oils are more aggressive toward exposed plastics, increasing the likelihood of plastic degradation. Degraded plastics can contaminate the oil and reduce its electrical insulation capacity. If the electrical insulation capability is significantly degraded, the transformer will fail.

The sound of a transformer reaching its failure point is akin to a transformer on a telephone pole blowing—like a loud gunshot or firecracker explosion.

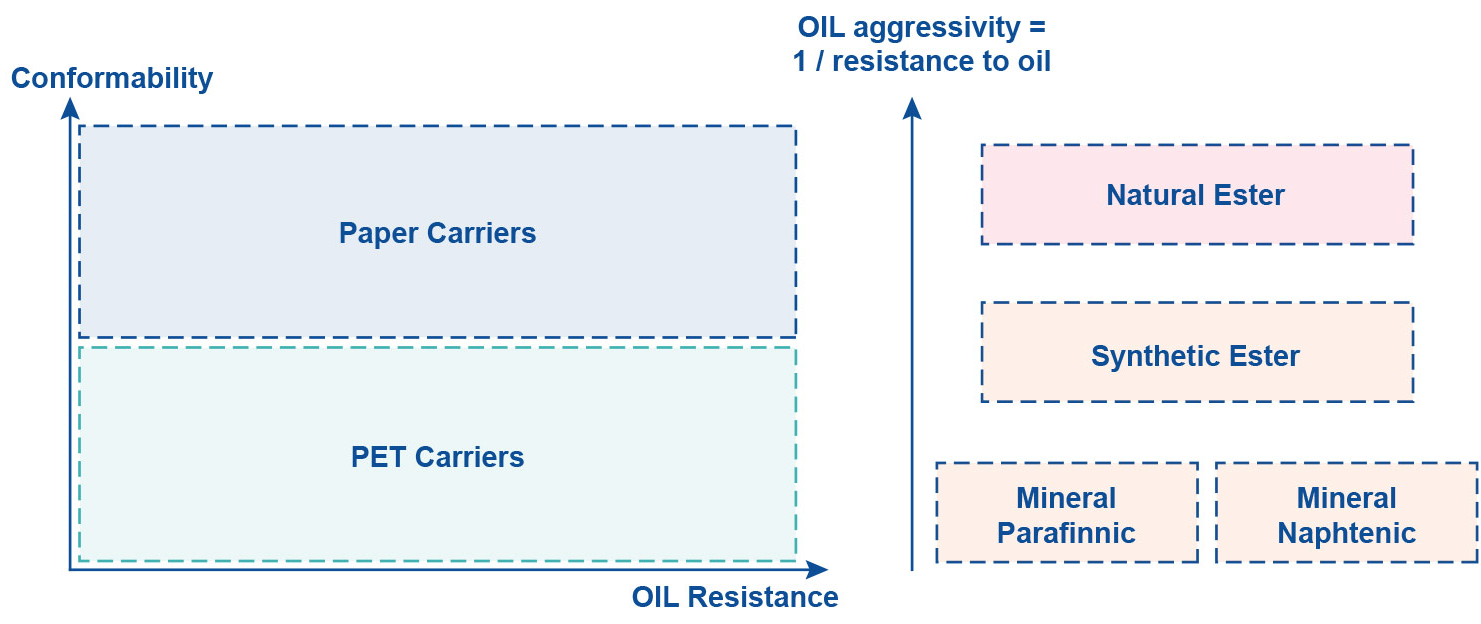

Filament Reinforced Tapes With Paper Backing vs. Polyester

As synthetic oils and ester oils are more aggressive toward plastics than mineral oils, products made of filament-reinforced paper perform better than those made of filament-reinforced polyester.

Filament-reinforced tapes with paper backings, such as PG.70, 6601, and Saint-Gobain’s newly formulated product in development, are the preferred option when it is necessary to evade the risk of air bubbles in insulation oils.

Typically, the presence of an air bubble in a transformer creates corona discharge, potentially resulting in premature failure. Tapes with paper backing facilitate complete oil penetration and eradicate the risk of air bubbles forming.

Products like PS.25 and PS.249, featuring a plastic film (polyester), typically have good performance. However, there is a higher probability of air bubbles getting trapped between the tape and electrical wires in green transformer applications. These products are more suitable for traditional mineral transformers, where the aggressiveness of the oil is comparatively lower.

Image Credit: Saint-Gobain

Additional factors to consider when selecting the optimal product for green transformer applications relate to oil compatibility and resistance. Customers prioritize products that do not dissolve in synthetic and natural ester oils, as this causes contamination and premature failure of the oil-filled transformers. Products with superior oil compatibility with natural esters can add years of life.

However, polyester filament tape products often excel in terms of oil resistance, while paper filament tape products demonstrate greater conformability and effectiveness in preventing problems such as corona discharge. In response, Saint Gobain has developed a new product to address these challenges, which will be available soon.

Product Spotlight: New In-Development Product Variation of CHR® 6601

This product is still in the development phase and is specially designed for robust air and oil-filled transformer applications, reinforcements, and insulation. It is comprised of glass fiber-reinforced paper backing with acrylic pressure-sensitive adhesive.

Its superior adhesion, tensile strength, and dielectric properties make it the optimal product for heavy banding and holding applications found in large-scale coil winding procedures, including transformers, motors, and generators.

Image Credit: Saint-Gobain

Acrylic Adhesive Tape Compatibility in Ester Fluids: A Clear Winner

To determine the compatibility of adhesive tapes in oil, numerous tests can be conducted.

The team at Saint-Gobain Tape Solutions has investigated the behavior and compatibility of numerous acrylic adhesive tapes following immersion in ester oils, including Natural Ester A, Cargill FR3, Synthetic Ester A, and Natural Ester B.

The swelling test and the peel adhesion test are two common tests. A summary of each test and the results is provided below.

- Swelling Test: The objective of this test is to assess the adhesive behavior following soaking in the ester oils described above. In this test, tapes are cut into strips of 25 mm or 10 mm in width and submerged into a jar filled with oil, ensuring complete saturation of each adhesive tape with each oil type.

The jars are sealed to prevent the entry of new oxygen. These tapes then undergo aging in an oven at 100 °C for 24 hours. Samples are then extracted for visual inspection and consistency testing.

The test results confirmed that Cargill FR3 and other natural ester oils were significantly less aggressive toward various adhesives when compared to synthetic oils. However, the latest product in development displayed exceptional resistance in all fluids without showing visible swell or damage.

- Peel Adhesion: This is a quantitative 180ᵒ peel adhesion assessment of the tape from an aluminum substrate, both before and after oil exposure. Sample preparation and aging are the same as for the swelling test. However, the adhesive tape strips are applied to a metallic surface prior to immersion in oil. The tapes are subsequently peeled at a consistent speed, and the resulting force is measured using a dynamometer.

In this test, CHR 6602 exhibited superior performance. This is likely because heat transmission of the fluids was efficient and did not affect the adhesive chemistry.

Understanding Interaction of Tapes Drives to Enhance Longevity

Understanding the interaction of adhesive tapes with oil is crucial in the design and manufacture of green transformers. Adhesive tapes must display robust adhesive interactions with bio-based ester oils, along with high tensile strength and absorption capabilities. This ensures optimal electrical performance, energy conservation, and a reduced risk of transformer failure.

As technologies advance and efforts to find safer and more sustainable solutions grow, bio-based transformers emerge as key tools for reducing pollution, minimizing fire risk, and producing safer alternatives that align with future needs.

The improved performance, reduced maintenance, and extended longevity of green transformers position them as a financially viable and environmentally responsible solution for the transmission and distribution of electricity.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.