Traditional ceramics, such as tiles and bricks, are famous for their ability to endure elevated temperatures. However, Fine Ceramics (or "advanced ceramics") possess far greater heat resistance compared to these materials.

Image Credit: Kyocera International, Inc.

While aluminum starts melting at approximately 660 ℃ (approximately 1,220 ℉), alumina Fine Ceramics only start to melt or decompose at temperatures beyond 2,000 ℃ (approximately 3,632 ℉).

Fine Ceramics Characteristics Video: Heat Resistance

Watch this video to learn about the Heat Resistant properties of Fine Ceramics. Video Credit: Kyocera International, Inc.

Heat and Thermal Shock Resistance

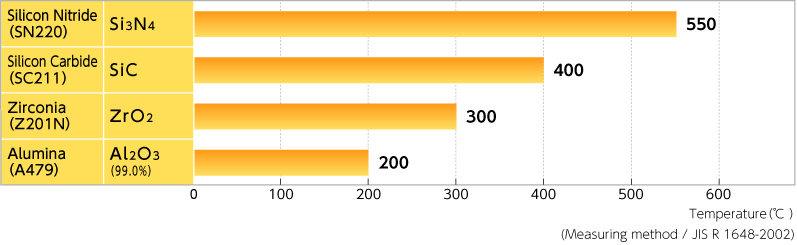

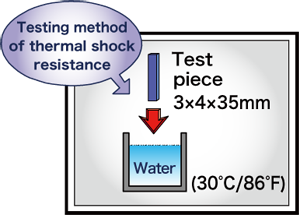

The heat resistant characteristics of Fine Ceramics are assessed by their melting temperatures, and by their levels of thermal shock resistance. Thermal shock resistance refers to a material's ability to endure quick temperature fluctuations.

Silicon nitride is particularly heat tolerant and exhibits outstanding resistance to thermal shock, as proved by heating the material to 550 ℃ (1,022 ℉) and quickly cooling it by immersion in water.

For this reason, silicon nitride is suitable for applications involving extreme temperature fluctuations, particularly in high-temperature industries like metal manufacturing and energy generation.

Thermal Shock Resistance (Water Immersion Test)

Image Credit: Kyocera International, Inc.

Testing Thermal Shock Resistance

A material's thermal shock resistance is evaluated by the difference between the temperature of the Fine Ceramic which was heated, rapidly cooled, and then fractured, and the temperature of the cooling media

Stresses are produced by temperature differences between the interior and surface of a test segment, which occur during rapid cooling.

When these stresses exceed the strength of the Fine Ceramic, fracturing occurs. These temperature variations are determined by the thermal conductivity of ceramics and the coefficient of heat transfer between the Fine Ceramic and the cooling media.

Image Credit: Kyocera International, Inc.

The stresses generated are calculated by multiplying Young's modulus, the coefficient of thermal expansion, and the temperature differences between the interior and surface of the Fine Ceramic.

Fine Ceramics Characteristics Video: Thermal shock resistance

Watch this video to learn about the Thermal Shock resistant properties of Fine Ceramics. Video Credit: Kyocera International, Inc.

This information has been sourced, reviewed, and adapted from materials provided by Kyocera International, Inc.

For more information on this source, please visit Kyocera International, Inc.