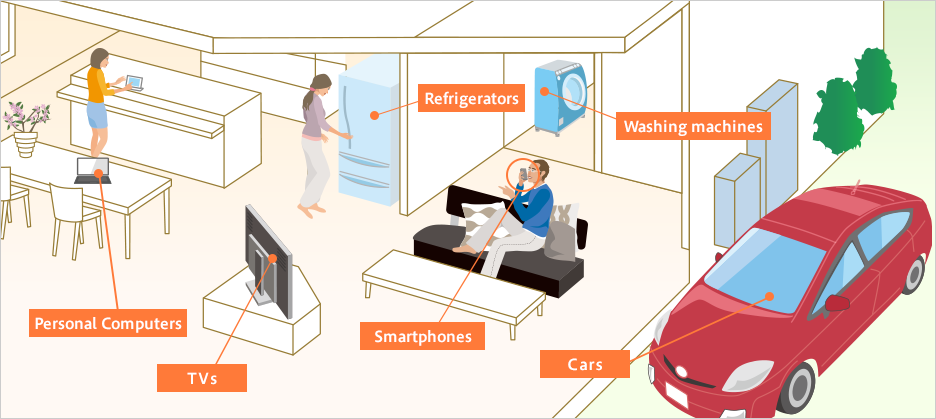

Integrated circuits, also known as semiconductors, are prevalent within the products that we utilize in our daily lives.

Image Credit: Kyocera International, Inc.

While semiconductors are renowned for their role in personal computers, they are also extensively integrated into smartphones, cars, televisions, washing machines, refrigerators, and other everyday appliances to enhance performance, safety, efficiency and convenience.

Any shortage of semiconductors will disrupt the global economy, as the majority of the consumer products we buy (and machines used to make them) depend on semiconductor technology. To state that semiconductors are indispensable to modern life would be no exaggeration.

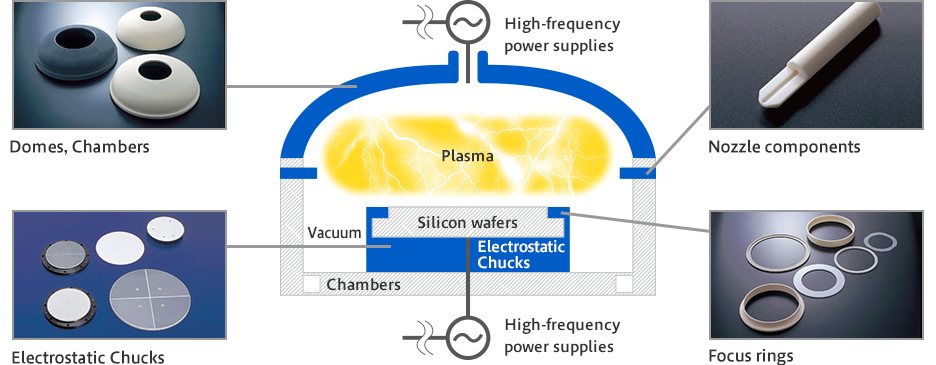

Fine Ceramics Play a Vital Role in Semiconductor Manufacturing Equipment

The process of manufacturing semiconductors incorporates stringent conditions where plasma is generated.

Plasma corrosion resistance is therefore a crucial attribute for components involved in semiconductor manufacturing equipment. The absence of plasma corrosion resistance will lead to contamination of semiconductors with unintended impurities, resulting in defective products.

For this reason, highly reliable Fine Ceramics with exceptional plasma resistance are more suitable for the semiconductor manufacturing process than glass, resins, and metals.

Major Fine Ceramic Components Perform Critical Functions Inside Semiconductor Manufacturing Equipment

Because of their superior plasma resistance, Fine Ceramic components are essential in environments involving the harsh conditions of plasma generation.

Image Credit: Kyocera International, Inc.

Improved Performance of Semiconductors Demands Increased Durability in Semiconductor Manufacturing Equipment

To enable the continually advancing performance of semiconductors, manufacturing equipment itself must also continue to evolve. This is seen in rising performance requirements for components used in semiconductor manufacturing equipment, which include greater durability to withstand intense plasma and associated high temperatures.

As a result, traditional components manufactured from materials like glass, resin, and metals are being substituted with Fine Ceramic counterparts.

This information has been sourced, reviewed, and adapted from materials provided by Kyocera International, Inc.

For more information on this source, please visit Kyocera International, Inc.