Sponsored by Specac LtdReviewed by Maria OsipovaJul 2 2024

Exploring the frontiers of chemistry and physics, materials science pushes the boundaries of what can be achieved. The field is witnessing significant scientific breakthroughs, especially in areas addressing the growing demands of energy and consumer electronics.

Within materials science, ATR-FTIR spectroscopy is a useful tool employed by researchers. Its applications range from identifying unknown materials to determining the composition and purity of substances, as well as delving into the chemical structure of materials. Moreover, FTIR spectroscopy proves invaluable in detecting chemical alterations induced by variations in temperature, pressure, or other environmental factors.

How Does ATR Spectroscopy Work?

The sample material is placed in close contact with a prism made from diamond, zinc selenide, or germanium. The infrared light enters the prism at an angle and undergoes internal reflection off the sample-prism interface. At the point of reflection, a small standing wave (known as an ‘evanescent wave’) forms and allows some energy to be absorbed by the sample, allowing an exact and sensitive absorption spectrum to be obtained. The basic setup is shown in the figure below.

Graphical representation of a single bounce ATR. Image Credit: Specac Ltd

To ensure that the beam of light is reflected rather than transmitted through the surface of the ATR crystal, the angle of incidence must be above the critical angle, which varies depending on the refractive index of the crystal material. The Specac Quest has a fixed angle of incidence of 45°, which is above the critical angle for all the ATR crystals offered, including diamond, zinc selenide, and germanium.

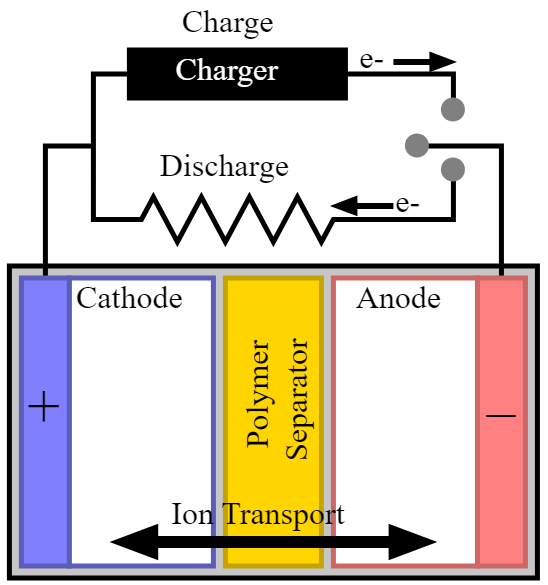

Application Example: Separator Materials for Lithium-ion Batteries

An illustrative application of FTIR spectroscopy is found in examining separator materials for fuel cells and lithium-ion batteries. Researchers utilize FTIR to assess structural changes brought about by processes to enhance membrane performance. While transmission FTIR may be the preferred method for thin film materials, ATR-FTIR also plays a crucial role.

Tkarcher, CC BY-SA 3.0, via Wikimedia Commons.

ATR is useful for analyzing and comparing films and coatings, for example, where one side of a material has been treated with a coating and the other is left untreated. Because ATR is a technique that probes only the near-surface layers, spectra taken on each side of the material should be different.

One research group examined a poly(ethylene oxide) coating imparted onto a commercial polypropylene separator for a lithium-sulfur battery1. They observed C-O-C stretching bands on the coated side of the material, which were absent on the uncoated side. This demonstrated that the coating had not soaked right through the material during application and had formed on one side only, as desired.

Functional Materials

Some materials have useful properties, such as magnetism, pyroelectricity, piezoelectricity, or energy storage. They are often termed ‘functional’ materials.2 They find applications as sensors in cameras and other detection equipment, luminescent emitters in display screens, or touch-sensitive components in touch screens.

Functional materials such as DTGS – a pyroelectric – and the photoelectric MCT material are used as detectors in IR spectroscopy.

A common type of transparent conductive oxide used in touchscreens and liquid crystal displays is zinc oxide (ZnO), while bismuth oxide (Bi2O3) has various applications in electronics and photocatalysis.

A class of materials extensively studied using spectroscopic methods, such as FTIR, is Metal Organic Frameworks (MOFs) and the related Covalent Organic Frameworks (COFs). These are three-dimensional compounds containing voids, or pores, which can be used to store gases or operate as catalysts.3 Because they consist of organic building blocks linked by metallic or covalent linkages, FTIR can easily be used to check for bands associated with forming bonds and look for depletion of bands associated with the precursor molecules used in their synthesis 4. ATR-FTIR is one of the most convenient methods for characterizing such materials since the final product is usually a finely powdered solid that can be analyzed easily.

General Advantages and Limitations of ATR-FTIR

Attenuated Total Reflectance Fourier-Transform Infrared (ATR-FTIR) spectroscopy is a potent tool within the realm of materials analysis. The technique has many advantages and faces relatively few limitations:

Advantages of ATR-FTIR:

- Non-destructive Nature: ATR-FTIR spectroscopy is usually a non-destructive method, facilitating the examination of solid and liquid samples without inducing any alterations to their inherent properties or structures.

- Fast Analysis: ATR-FTIR workflow has few steps and is a rapid technique, making it well-suited for high-throughput analyses.

- Versatility: ATR-FTIR can analyze almost any non-gaseous material, accommodating solids, powders, liquids, and pastes.

- High Surface Sensitivity: ATR-FTIR is highly sensitive to the surface chemistry of materials, making it ideal for analyzing coatings and other surface alterations.

Limitations of ATR-FTIR:

- Surface Analysis Constraint: If, on the other hand, a bulk measurement is required, the analyst must be confident that near-surface layers (typically within a depth range of a few microns) are representative of the whole material.

- Chemical Compatibility: Since ATR requires close contact with the sample materials, the holders and crystal materials can be prone to chemical attack. While chemically resistant diamond is often employed for ATR, the mounting plate is usually stainless steel or similar.

- Spectral Artifacts: ATR-FTIR spectra are susceptible to influences like crystal temperature, pressure, and contact force, potentially introducing spectral artifacts that may impact the accuracy of the analysis.

In summary, ATR-FTIR spectroscopy is a versatile and sensitive method offering substantial advantages in materials analysis. Nevertheless, consideration of sample preparation and analysis conditions is imperative to ensure the precision and reliability of results, given the technique's inherent limitations.

References

- Poly(ethylene oxide)-coated double-layer separator for lithium-sulfur battery, J.M. Conder, C.Hänsel, S.Trabesigner, P. Novák, L. Gubler. PSI Electrochemistry Laboratory – Annual Report 2015, Paul Scherrer Institut (available at: https://www.psi.ch/lec)

- https://www.imperial.ac.uk/materials/research/functional/

- Metal—organic framework, Wikipedia. https://en.wikipedia.org/wiki/Metal%E2%80%93organic_framework

- Acridine-Functionalized Covalent Organic Frameworks (COFs) as Photocatalysts for Metallaphotocatalytic C-N Cross-Coupling, M. Traxler, S. Gisbertz, P. Pachfule, J. Schmidt, J. Roeser, S. Reischauer, B. Pieber, A. Thomas, Angew. Chem. Int. Ed. 2022, 61, e202117738 (DOI: https://doi.org/10.1002/anie.202117738)

This information has been sourced, reviewed and adapted from materials provided by Specac Ltd.

For more information on this source, please visit Specac Ltd.