X-Ray Fluorescence (XRF) and X-Ray Diffraction (XRD) are critical assets in cement production, as they determine the elemental and structural composition of cement clinker. Analytical techniques are used to guarantee the conformity, consistency, and performance of cement, which significantly impacts the structural integrity of infrastructure and buildings.

XRD has a significant role in offering cement manufacturers the ability to analyze clinker phases and determine the exact mineralogical composition. These details are critical in quality control of the final product and improving process efficiency.

The reliability and accuracy of XRD measurements depend on using Standard Reference Materials (SRMs). SRMs serve as checkpoints that enable analytical method validation for XRD instruments and ensure phase quantification accuracy.

Any deviation in cement production can lead to structural issues, making SRMs essential for quality control. They validate the comparability and precision of results throughout XRD analyses and allow for consistent cement production processes that meet the demanding industry standards and regulatory requirements. Cement manufacturers can verify their products through the use of SRMs, and not only meet specifications but also add to the sustainability and long-term safety of constructed infrastructure.

Instrument

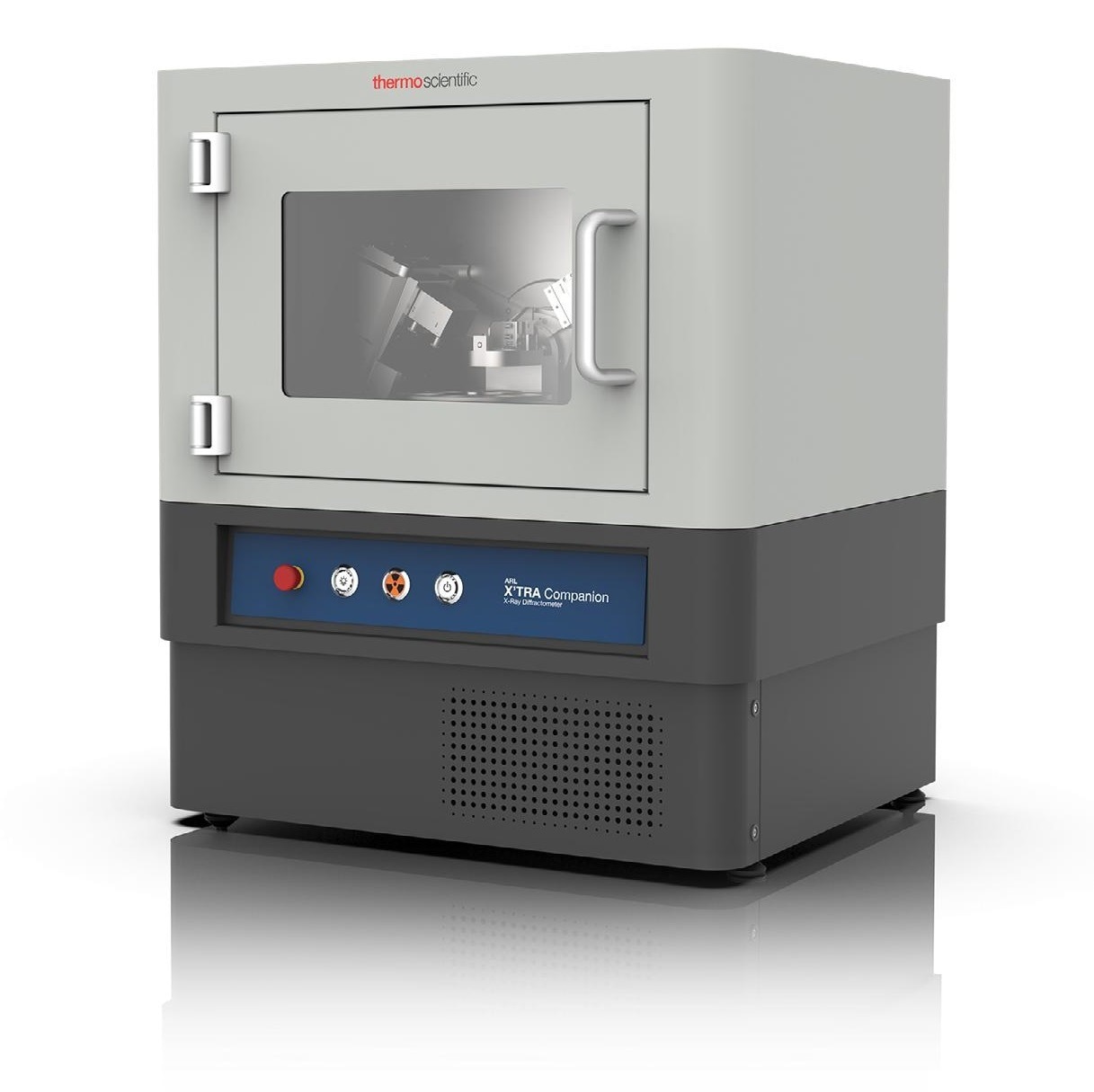

Figure 1 shows the Thermo Scientific™ ARL™ X’TRA Companion X-Ray Diffractometer. It is a simple, user-friendly benchtop XRD system for process control and more advanced applications.

The ARL X’TRA Companion uses a 160 mm radius θ/θ goniometer in Bragg-Brentano geometry and a 600 W X-Ray source (Cu or Co).

Soller slits and divergence manage the axial and radial adjustment of the beam, while a variable beam knife reduces air scattering. Additional options include an integrated water chiller. With a state-of-the-art solid-state pixel detector (55 x 55 μm pitch), the ARL X’TRA Companion offers exceptionally speedy data collection and arrives with one-click Rietveld quantification capabilities and automated result transmission to a LIMS.

Figure 1. ARL X’TRA Companion diffraction system. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Experimental

Powdered (ball milled; 2 min, 30 Hz) NIST SRM 2686, 2687, and 2688 clinkers were measured in reflection with an ARL X’TRA Companion with Cu Kα radiation.

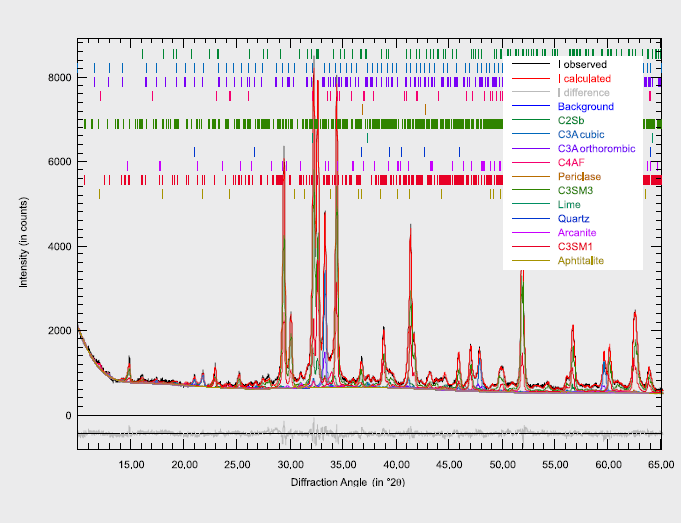

The samples were measured 21 times with 10 min per run to calculate the reproducibility according to ASTM C1365 (c.f. Figure 2). Using a fundamental parameters approach, phase quantification was performed with Profex (BGMN algorithm).1 Reference structures were chosen according to Aranda et al. 2

Figure 2. Rietveld fit of SRM 2687. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Results

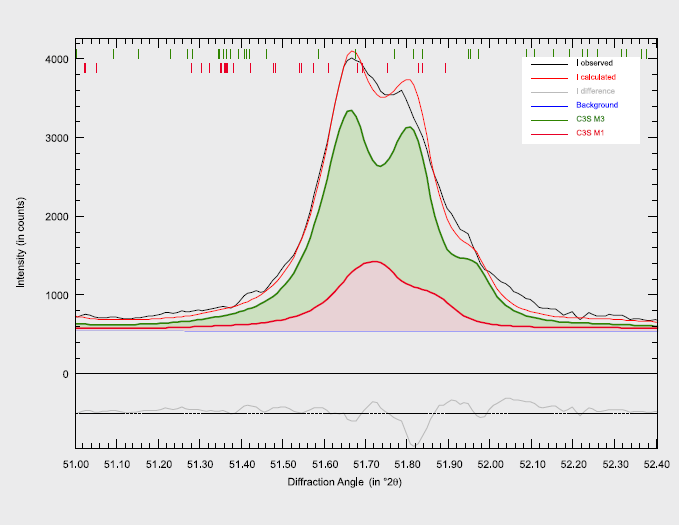

Standard deviations were calculated using the results of 21 consecutive analyses and contrasted with limits given by ASTM C1365. Both accuracy and repeatability are within the limits of ASTM C1365 and GB/T 40407-2021 (c.f. Table 1 and 2; reference values shown were available). In addition, refinement of cubic and orthorhombic C3A and M1 and M3 polymorphs of C3S is possible with good repeatability (c.f. Figure 3).

Figure 3. Rietveld fit of SRM 2687 (51.0-52.40°2θ) showing theoretical profiles of C3S M3 (green) and C3S M1 (red). Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Table 1. Accuracy of average values of 21 consecutive analyses of Clinker SRMs 2686, 2687 and 2688 (Standard deviations in 1 σ). Source: Thermo Fisher Scientific – Production Process & Analytics

| SRM 2686 |

SRM 2687 |

SRM 2688 |

| In weight % |

Profex |

NIST value |

Profex |

NIST value |

Profex |

NIST value |

| C3S M1 |

18.53 (0.85) |

|

24.43(1.22) |

|

45.22 (1.15) |

|

| C3S M3 |

39.32 (0.77) |

|

48.54 (1.18) |

|

20.78 (1.17) |

|

| C3S tot |

57.85 (0.38) |

58.6 (2.0) |

72.98 (0.37) |

71.24 (0.64) |

66.00 (0.23) |

64.95 (0.52) |

| C2S β |

20.10 (0.36) |

23.3 (1.4) |

8.71 (0.43) |

12.57 (0.61) |

14.04 (0.31) |

17.45 (0.48) |

| C3A C |

0.95 (0.32) |

|

10.34 (0.34) |

|

1.26 (0.29) |

|

| C3A O |

3.43 (0.48) |

|

3.39 (0.26) |

|

3.44 (0.44) |

|

| C3A tot |

4.38 (0.26) |

2.1 (1.2) |

13.72 (0.13) |

11.82 (0.61) |

4.70 (0.23) |

4.99 (0.25) |

| C4AF |

12.51 (0.18) |

14.1 (0.7) |

2.61 (0.17) |

2.81 (0.34) |

14.08 (0.24) |

12.20 (0.42) |

| Lime* |

0.16 (0.04) |

|

0.15 (0.05) |

|

0.30 (0.05) |

|

| Periclase |

3.99 (0.09) |

3.3 (1.0) |

0.49 (0.06) |

|

0.05 (0.05) |

|

| Quartz |

0.62 (0.04) |

|

0.11 (0.04) |

|

0.25 (0.04) |

|

| Alkali Sulphates |

0.38 (0.07) |

|

1.23 (0.13) |

0.92 (0.08) |

0.57 (0.12) |

|

* Reference values not shown due to hydration to Portlandite

Table 2. Precision of 21 consecutive analyses of Clinker SRMs 2686, 2687 and 2688. Source: Thermo Fisher Scientific – Production Process & Analytics

| 1 σ (in weight %) |

SRM 2686 |

SRM 2687 |

SRM 2688 |

ASTM C1365 |

| C3S tot |

0.38 |

0.37 |

0.23 |

0.74 |

| C2S β |

0.36 |

0.43 |

0.31 |

0.49 |

| C3A tot |

0.26 |

0.13 |

0.23 |

0.47 |

| C4AF |

0.18 |

0.17 |

0.24 |

0.64 |

| Periclase |

0.09 |

0.06 |

0.05 |

0.23 |

Conclusion

The monitoring of specific polymorphs similar to C3S M1 and M3 is critical, because the existence of the polymorphs has an impact on the compressive strength of the finished product. This is particularly important for alternative fuels used during production, as changes in the chemistry usually favors one form over another.

Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Data on NIST SRMs 2686, 2687 and 2688 collected with ARL X’TRA Companion XRD demonstrate results in compliance with ASTM C1365 and GB/T 40407-2021 in terms of repeatability and accuracy. It is possible to refine both C3S M1 and M3 polymorphs using Profex in tandem with good repeatability. The ARL X’TRA Companion is an ideal solution for any routine analysis task in the cement industry.

References and Further Reading

- N. Döbelin, R. Kleeberg, J. Appl. Crystallogr. 2015. 48, 1573-1580.

- M.A.G. Aranda, A.G. De la Torre, L. León-Reina, Rev. Mineral. Geochem. 2012. 74, 169–209.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.