Paper can be fabricated from all different kinds of materials such as, reeds, flax, cotton, and even bagasse (sugarcane pulp). However, the majority of paper products are made from treated wood fibers.

Processing wood for paper manufacturing is done with pulp mills and paper mills, which require lots of chemicals and energy. Implementing high-standard screening and quality control (QC) measures is crucial along the entire production chain, from the timber to the finished paper product.

This article describes how near-infrared spectroscopy (NIRS) can simultaneously track several key QC parameters throughout the entire pulp and paper manufacturing process.

Introduction to the Pulp and Paper Industry

The pulp and paper industry manufactures cellulose-based products derived from different types of wood, which are then sold on the market. To produce their final products covering many applications, pulp and paper mills process timber using mechanical and chemical methods.

Figure 1 shows the global paper, tissue, and board production shares listed by country in 2019.1 China, the United States, Brazil, and Japan account for more than half of the global production, with China taking up the largest market share.

![Global paper, tissue, and board production share by country in 2019 [1].](https://www.azom.com/images/Article_Images/ImageForArticle_23381_17084006515302086.jpg)

Figure 1. Global paper, tissue, and board production share by country in 2019 1. Image Credit: Metrohm Middle East FZC

Wood, from which paper derives, is mainly composed of cellulose, hemicellulose, and lignin. The variable microstructures in timbers allow wood to be classified as softwood or hardwood. Coniferous trees with needles and cones, such as pines, firs, and spruces, are categorized as softwood. Deciduous trees, those with leaves and seeds such as oak, beech, and walnut, are the hardwood species.

The hardwood fibers are shorter than those in softwoods and produce weaker paper. However, the final product is well-suited for printing applications due to the smooth, opaque finish. Softwoods typically have long and strong fibers that give the paper its strength. Consequently, softwoods are commonly used to make boxes and other packaging.

The Pulp and Paper Manufacturing Process

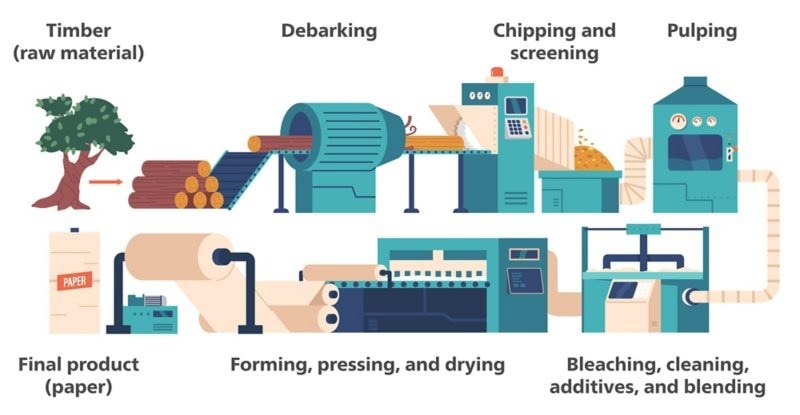

The pulp and paper manufacturing process is split into four main stages, namely: raw material preparation, pulping, bleaching, and papermaking. Each stage is detailed below. A general overview of the complete process can be seen in Figure 2.

Figure 2. Illustration of the general pulp and paper manufacturing process. Image Credit: Metrohm Middle East FZC

Raw Material Preparation

Preparing the raw materials for pulping the timber involves size reduction, debarking, chipping, and screening.

Bark is considered to be a contaminant in the pulping process. As implied by the name, debarking strips the outer layer of bark from logs before chipping. The logs are then run through a chipping machine. This creates wood chips of a consistent size and shape to optimize the efficiency of the pulping process.

The wood chips are then screened as part of the final stage of raw material preparation. Any chips that are too small or large are removed from the bulk and used for either energy recovery or sent back in the line for further reprocessing.

Pulping

In the pulping process, lignin and cellulose linkages are broken down suing a high-pressure digester and a number of different chemicals. The most frequently used wood pulping is known as the Kraft process.

An aqueous solution of sodium hydroxide and sodium sulfide, also known as “white liquor”, selectively dissolve the lignin. The mixture is then discharged from the digester after 2-4 hours have passed. The pulp is treated through a washing process to separate it from unwanted byproducts, including “black liquor”, pulping chemicals, and wood waste.

This treated pulp, referred to as “brown stock”, is now ready for bleaching.

Bleaching

Bleaching involves introducing the treated pulp to various chemical combinations which are determined on the end use of the paper product.

Common bleaching chemicals include chlorine, chlorine dioxide, hydrogen peroxide, oxygen, caustic soda, and sodium hypochlorite. Due to concerns over the production of chlorinated byproducts, such as dioxins, furans, and chloroform, manufacturers have moved away from using chlorinated chemicals during the bleaching process.

The Effluent that is produced during this stage is collected in tanks for reuse in other stages as wash water or sent away for wastewater treatment.

Papermaking

To prepare the pulp for the next stage manufactures employ a series of techniques such as slushing, blending pulps with different qualities, mechanical pretreatments, and introducing fillers and other additives to produce the paper. As with other stages, the type of process is contingent on the desired paper quality.

Therefore, being able to screen and monitor various quality control parameters before, during, and after the manufacturing process is vitally important to produce high-quality paper products that consumers can rely on.

Near-infrared (NIR) spectroscopy is a suitable method that can be leveraged for quality control analysis throughout all stages of pulp and paper production processes.

This article outlines how NIRS works in general and describes how it offers several advantages when compared to other methods for QC and screening in the pulp and paper industry.

Near-Infrared Spectroscopy Technology Overview

Light and matter interact in a number of different ways usually denoted by absorption, reflection, scattering, emission, and transmission. When evaluating how light is used in spectroscopic methods, it is usually described in wavelength or wavenumbers.

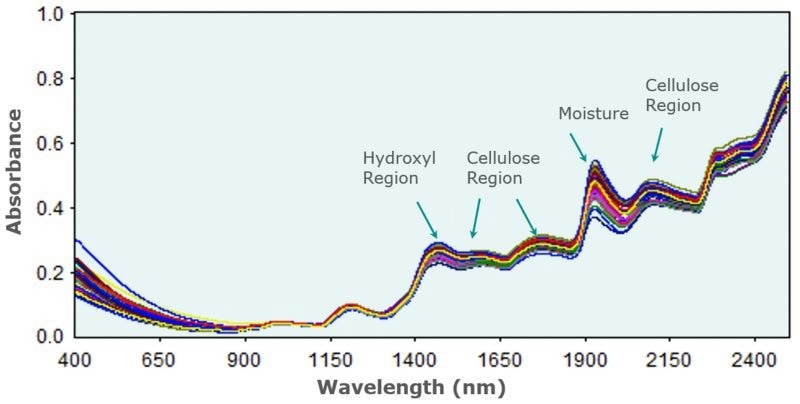

NIR spectrometers, such as the Metrohm DS2500 Solid Analyzer, measure these light-matter interactions to generate spectra full of information as shown in Figure 3.

Figure 3. Near-infrared spectra resulting from the interaction of NIR light with paper samples. Note the peaks attributed to moisture, cellulose, and hydroxyl content. Image Credit: Metrohm Middle East FZC

NIRS is an excellent method for the quantification of certain chemical parameters such as water content (moisture), kappa number, lignin content, and resin content as it is sensitive to the presence of certain functional groups. As this interaction also depends on the sample matrix, NIRS also facilitates the detection of other physical parameters such as density and strength.

The abundance of information contained in the resulting spectrum makes NIRS ideal for quick multi-parameter analysis for almost any sample.

NIRS Measuring Mode for Wood Pulp and Paper Products

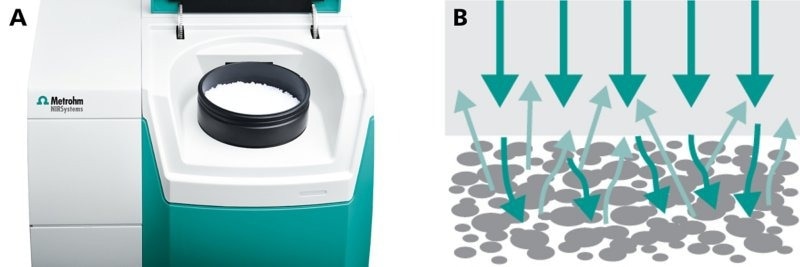

Deciding which is the best NIRS measuring mode to use is dependent on the sample type. It is recommended to use the diffuse reflection mode when analyzing solids like wood pulp and paper products, this is shown in Figure 4. In this mode, the sample is exposed to NIR light, some of which it absorbs as it passes through the sample. Any unabsorbed NIR light is reflected back and measured by the detector.

Figure 4. a) Measurement of solid samples is typically done in sample cups. b) The measurement mode is known as diffuse reflection, where the sample is exposed to light and the diffuse reflected light gets absorbed. Image Credit: Metrohm Middle East FZC

Advantages for Paper Producers When Using NIRS

Users can gain a number of advantages when using NIR spectroscopy for analytical applications, especially where quality control and screening are concerned. Time and cost savings are among the man benefits as sample preparation is not required, which means results can be accessed in seconds.

NIRS is a multi-parameter analysis technique, which eliminates the need to run several separate time-intensive analyses across a range of instruments only to achieve the same results. The non-destructive nature of the technique protects samples and as it does not use any chemical reagents; the process is environmentally friendly.

NIRS is also verified for quality control purposes by standard organizations such as ASTM.2 Furthermore, can be operated by non-technical personnel, due to its user-friendliness which sets it apart from more complex analytical techniques.

Product Screening and QC Parameters for Pulp and Paper Production

All research, development, and quality control processes are dependent on laboratory testing. Pulp and paper mills employ a range of standardized test methods for identifying key physical and chemical properties in raw materials, intermediates, and final products.

Table 1 shows the key test parameters for the screening and QC of pulp and paper products.

Table 1. Various screening and quality control parameters for pulp and paper products along with the typical method used for analysis. Source: Metrohm Middle East FZC

| Part of process |

Parameter |

Conventional analysis method |

| Raw material analysis |

Bulk density |

Densimetry |

| Moisture content |

Karl Fischer titration |

| Research for genetic improvement: |

| Pulp yield |

Gravimetric analysis |

| Cellulose content |

Gravimetric analysis |

| Lignin content |

Hydrolysis / Gravimetric analysis / Photometry |

| Chemical pulping and bleaching |

Lignin content |

Hydrolysis / Gravimetric analysis / Photometry |

| Cellulose content |

Gravimetric analysis |

| Resin content |

HPLC |

| Kappa number |

Titration |

| Breaking strength |

Short span Compression Test (SCT) |

| Buckling strength |

Ring Crush Test (RCT) |

| Tensile strength |

Tensometry |

| Pulp freeness |

Canadian Standard Freeness Test (CSF) |

| Liquor and crude tall oil |

Titration |

| Finished product QC |

Moisture content |

Karl Fischer titration |

| Paper grammage |

Gravimetric analysis |

| Ash content |

Oven |

| Silicone levels |

GC |

| Hardwood / Softwood ratio |

Microscopy |

| Coating layers |

Photometry |

A Turnkey Solution for Pulp and Paper Analysis

The Metrohm NIRS solution for pulp analysis is accompanied with a ready-to-use pre-calibration model for the identification of several parameters, such as kappa number, breaking strength, buckling strength, tensile strength, density, and pulp freeness as shown in Table 2.

This ready-to-go pre-calibration set solution can be used as a turnkey starter model without any prior method development.

Table 2. Available NIRS pre-calibrations for analysis of key quality parameters in pulp products. Source: Metrohm Middle East FZC

| Parameter |

Range |

Standard Error of

Cross Validation (SECV) |

R2 |

| Applied density (g/cm3) |

0.2–0.65 |

0.039 |

0.855 |

| Buckling strength (MPa) |

20–94 |

7.4 |

0.821 |

| Breaking strength (MPa) |

6–32 |

2.6 |

0.828 |

| Tensile strength (MPa) |

6–68 |

5 |

0.905 |

| Kappa number |

0–175 |

3.8 |

0.996 |

| Pulp freeness (mL) |

130–800 |

72 |

0.766 |

Outlined in Table 3 are the results of the quality control of processed wood pulp. This shows that visible near-infrared spectroscopy (Vis-NIRS) can clearly identify six different QC parameters (kappa number, applied density, pulp freeness, breaking strength, buckling strength, and tensile strength) simultaneously in wood pulp.

Table 3. Example of multi-component analysis in wood pulp using Vis-NIRS. Source: Metrohm Middle East FZC

| Parameter |

Figures of merit |

| R2 |

Standard Error of

Calibration (SEC) |

SECV |

| Kappa number |

0.986 |

2.9 mg |

3.0 mg |

| Applied density |

0.903 |

0.0292 g/cm3 |

0.0308 g/cm3 |

| Pulp freeness |

0.785 |

68 mL |

71 mL |

| Breaking strength |

0.803 |

2.5 MPa |

2.6 MPa |

| Buckling strength |

0.768 |

7.2 MPa |

7.4 MPa |

| Tensile strength |

0.875 |

5 MPa |

5 MPa |

Summary

NIRS offers a turnkey solution for the quality control and screening processes used in today’s paper manufacturing industry. NIRS has several advantages compared to traditional reference laboratory methods. Besides saving manufacturers time and money, NIRS helps producers deliver high-quality products. It is also environmentally friendly and user-friendly facilitating simultaneous analysis of several key quality parameters in just a single scan.

Users, including inexperienced personnel, can receive their results relating to the kappa number, applied density, pulp freeness (CSF), breaking strength (SCT), buckling strength (RCT), and tensile strength in wood pulp in approximately 30 seconds.

NIRS also offers close control over production processes as data is generated on an increased frequency when compared with other standardized laboratory techniques.

References

- Statista Research Department. Paper production global capacity share by country. Statista. https://www.statista.com/statistics/664968/global-paper-production-capacity-share-by-country/ (accessed 2023-11-23).

- ASTM International. Standard Practices for Infrared Multivariate Quantitative Analysis; ASTM E1655-17; ASTM International, 2018.

This information has been sourced, reviewed and adapted from materials provided by Metrohm Middle East FZC.

For more information on this source, please visit Metrohm Middle East FZC.