Protecting the inner core of an optical table from spillages and exposure to liquids such as water-cooled or liquid dye, coffee, and soft drinks is crucial. This prevents any significant contamination from reaching deep into the honeycomb core and protects the stability of the table.

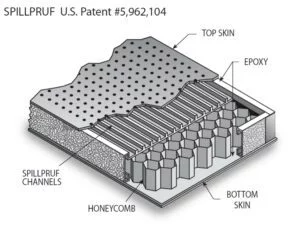

The SPILLPRUF™ configuration closes entire rows of mounting holes to safely channel liquids away from the table’s internal honeycomb core. This design provides exceptional honeycomb protection by sealing entire rows of holes, unlike tables with individually sealed holes that must be laboriously vacuumed to clean up spills.

With SPILLPRUF, cleanup is faster and more efficient, and it does not necessitate the removal of apparatus from the tabletop.

Figure 21.1. SPILLPRUF Spill Management System. Image Credit: Kinetic Systems, Inc

SPILLPRUF Increases Table Rigidity

The all-metal construction of SPILLPRUF increases the stiffness of the table due to its reinforced truss-like double-top skin. KSI applies the same principle used to improve stiffness in aircraft wings.

Due to the fact some alternative designs employ a sequence of low-modulus plastic dimpled membranes between the skin and core, table stiffness is, in effect, reduced.

Metal cup designs add weight, and while they increase deflection, they do not stiffen the table.

SPILLPRUF Maintains Table Thermal Conductivity

KSI’s SPILLPRUF all-metal construction enables rapid heat flow throughout, a feature that eliminates tabletop distortion caused by uneven expansion and contraction.

Alternative designs typically incorporate a plastic membrane under the top skin which generates slower heat transfer and leads to flatness degradation.

SPILLPRUF – A Better Technology For Handling Spills

The patented SPILLPRUF technique is a unique approach that protects the inner core of KSI’s honeycomb optical tables from spills; SPILLRUF solves a problem many customers have with individually sealed holes.

Spilled liquids always randomly drain into several holes over a wide area. With the method of individually sealing holes, each hole must be painstakingly vacuumed out. During cleanup, cleaning fluids must be poured into every hole and then vacuumed to extract the cleaning fluids.

To ensure cleaning has been completed in the correct manner, this process has to be repeated several times. Moreover, all apparatus must be removed from the tabletop to enable access to holes.

The SPILLPRUF design siphons and isolates fluids off into an aluminum channel protecting the honeycomb material. This channel completely isolates spills and provides greater structural integrity to the tabletop through additional damping.

Cleanup can be readily achieved by simply tilting the isolated tabletop (pneumatic leveling valves also enable this process), placing a vacuum nozzle in each of the lowest rows of holes, and extracting any fluids and cleaning solution. As fluids are drained from the lowest hole in each row, cleaning can be carried out without removing any of the apparatus from the tabletop.

This information has been sourced, reviewed and adapted from materials provided by Kinetic Systems, Inc.

For more information on this source, please visit Kinetic Systems, Inc.