Whichever model you choose, rest assured that all tables manufactured by Kinetic Systems Inc. have been done so using precision tooling and high-quality materials. The only difference between the tables is the amount of internal damping.

Image Credit: Kinetic Systems, Inc

Using a state-of-the-art design concept that leverages aerospace-grade epoxy laminated steel and honeycomb structural sandwich beams, KSI offers highly rigid optical tables and breadboards.

The exceptional stiffness and lightweight honeycomb lattice make it ideal for structurally efficient optical tables. Moreover, due to the honeycomb structure's inherently high natural frequency, this concept produces less vibration than similarly sized solid granite or ribbed cast iron designs.

All KSI’s standard honeycomb optical tables come equipped with ferromagnetic stainless steel top skins, carbon steel bottom skins and sides, hexagon cell honeycomb core, corrosion-resisting plated steel, a high shear modulus, and a proprietary damped epoxy formulation. All high-precision honeycomb cores are manufactured in-house at KSI. KSI incorporates steel C-channels treated with a damped laminate when assembling each table's side and end panels for additional stiffness and damping.

Epoxy-lamination is conducted in a pressurized environment with the top skin resting against a precision master tool plate. During the curing phase of the epoxy, the precision flatness of the master tool plate is, in effect, “frozen” and transferred to the working surface (top skin) of the honeycomb optical table or breadboard.

Mounting holes can be drilled or tapped into the tabletop and arranged in a grid pattern of 1″ or 25 mm spacing. This process occurs before assembly using KSI’s custom-designed CNC drilling machines. Subsequently, any defects such as chips are eliminated. At the same time, the top skin and SPILLPRUF core are cleaned thoroughly using a high-pressure, high-temperature, neutral detergent spray, which ensures a chip-free tabletop.

Finally, using a proprietary mechanical method, the steel side and end panels are attached to the top and bottom skins for improved strength. The top surface is lightly sanded to create a smooth, non-reflective finish, and the sides are laminated with a high-pressure, scratch-resistant, granite-look laminate trim.

A scratch-resistant, non-reflective black polyurethane finish is applied to the bottom surface. Before distribution, all tables were examined to check for dynamic compliance, natural frequency, damping, and flatness.

Performance Specifications

For Typical 4’ x 8’ x 12″ Table

Source: Kinetic Systems, Inc.

| |

5300 |

5200 |

5100T |

5100H |

5100 |

| Flatness (overall) |

± 0.005″ |

± 0.005″ |

± 0.005″ |

± 0.005″ |

± 0.005″ |

| Damped natural frequency |

220 Hz |

230 Hz |

245 Hz |

270 Hz |

250 Hz |

| First resonance transmissibility Q |

2 to 6 |

6 to 9 |

9 to 13 |

13 to 18 |

15 to 20 |

Deflection

under 250 lb concentrated load at center

|

£ 7.0

(10) -5 in. |

£ 7.0

(10) -5 in. |

£ 7.0

(10) -5 in. |

£ 7.0

(10) -5 in. |

£ 9.5

(10) -5 in. |

| First resonance corner compliance |

1.8 m in/lb |

5 m in/lb |

8 m in/lb |

25 m in/lb |

25 m in/lb |

| Max. dynamic deflection coefficient |

£ 0.3

(10) -3 in. |

£ 0.5

(10) -3 in. |

£ 0.6

(10) -3 in. |

£ 0.7

(10) -3 in. |

£ 0.9

(10) -3 in. |

| Max. isolated relative motion* |

£ 0.8

(10) -9 in. |

£ 1.3

(10) -9 in. |

£ 1.5

(10) -9 in. |

£ 1.9

(10) -9 in. |

£ 2.4

(10) -9 in. |

| Core shear modules |

225,000

psi |

225,000

psi |

225,000

psi |

225,000

psi |

225,000

psi |

*Performance with isolation under a light traffic random floor vibration condition of W Q =10 -10 g 2 /Hz

Features

All KSI Tables Feature:

- High-Efficiency Broadband Damping

- Low Reflective Surfaces

- Plated Steel Precision formed Honeycomb Core

- SPILLPRUF™ Spill Management System

Source: Kinetic Systems, Inc.

| |

5300 |

5200 |

5100T |

5100H |

5100 |

| Quad-Tuned Damping |

YES |

NO |

NO |

NO |

NO |

| Tuned Damping |

YES |

YES |

YES |

NO |

NO |

| Broadband Damping |

YES |

YES |

YES |

YES |

YES |

| Ferromagnetic Stainless Steel Top Skin |

3/16″

Thick |

3/16″

Thick |

3/16″

Thick |

3/16″

Thick |

1/8″

Thick |

| Carbon Steel Bottom Skin, Black Polyurethane Finish |

3/16″

Thick |

3/16″

Thick |

3/16″

Thick |

3/16″

Thick |

1/8″

Thick |

| Plated Steel, Precision Formed Honeycomb Core |

YES |

YES |

YES |

YES |

YES |

| Maximum Length* |

20’ |

20’ |

20’ |

20’ |

12’ |

| Maximum Width |

6’ |

6’ |

6’ |

6’ |

4’ |

| Maximum Thickness |

36″ |

36″ |

36″ |

36″ |

12″ |

*Tables longer than 16’ are custom.

KSI Optical Table Damping Options

Quad-Tuned Damping

KSI’s Ultimate Performance 5300 Series tables are equipped with “quad-tuned” damping together with the broadband damping qualities of the epoxy. This method uses independently tuned absorbers, which are inserted into the four corners of the table.

These absorbers are tuned to the two lowest natural frequencies (bending and torsion) of each optical table known as narrow-band selective damping. This is achieved using four frequency-tuned, mass-spring resonators dry-damped and tuned to resonant response, 180° out of phase, with the lowest natural mode frequency of the table.

The out-of-phase inertial forces of each resonator mass has the capacity to cancel or “absorb” any table motion at its natural frequency, as stated in den Hartog: “These tuned absorbers provide uniform damping performance over a broad temperature range. Competitive damping using “lossy” materials is temperature sensitive and can vary widely, particularly at lower than normal temperatures.” 1

Tuned Damping

KSI’s 5200 and 5100T series tables offer superior performance qualities and feature the same assembly as the 5300 Series tables with the exception that tuned absorbers are embedded in the table. Additional damping is achieved through the energy-dissipating properties of KSI’s proprietary epoxy which is used during table construction.

Broadband Damping

KSI’s 5100H and the 5100 series are cost-effective options that do not use tuned absorbers. Instead, all dampening properties come through the energy-dissipating features of the proprietary epoxy. In this series, a thick coating of epoxy covering 100% of the inside surfaces of the top and bottom skins of the table is applied to achieve energy dissipation. Known as “free layer” or “broadband” damping, this method is particularly effective across all high-frequency resonances of the table.

The tables’ dynamic compliance, modal frequencies, and damping properties are achieved using cutting-edge instrumented impulse force hammers, accelerometers, and a Fast Fourier Transform (FFT) program in a portable personal computer for storage and graphical presentation. 2

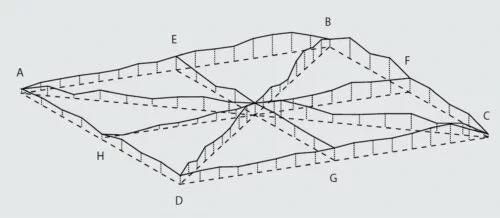

Figure 23.1. 3-dimensional "Union Jack" table flatness graph. Image Credit: Kinetic Systems, Inc

Flatness can be determined using an electronic level with a resolution of ±1 arcsec or 4.8 microinches per inch. Flatness readings are recorded digitally along eight lines that run the perimeter of outside holes, principal diagonals, and through the center of the table. These are then graphed in “Union Jack” format. Standard flatness for all tables is ±0.005 in. (±0.13 mm) in the measured perimeter. Breadboard flatness is ±0.004 in. (±0.1 mm) per 24 in. (610 mm.)

For Special Requirements

KSI’s engineers are on hand to answer questions related to skin and core material options, including aluminum, nonmagnetic stainless steel, and Invar. All KSI Optical Tabletops are customizable for length and width and special shapes, cutouts, and notches can be incorporated.

For additional technical information, see Isolation Basics, Optical Tables 101, and VIBRAPLANE sections.

KSI’s team of engineers will work with you to help you find with the best solution to fit your needs.

References

- den Hartog, J.P. “Mechanical Vibrations,” Chapter 3, McGraw-Hill Book Co., 1956

- Halversen,W.G. and D.L. Brown, “Impulse Technique for Structural Frequency Response Testing”, Sound and Vibration, November, 1977

This information has been sourced, reviewed and adapted from materials provided by Kinetic Systems, Inc.

For more information on this source, please visit Kinetic Systems, Inc.