When conducting laser diffraction particle-size analysis with specific liquid dispersants, thermal anomalies may occur, leading to data quality issues and necessitating extended equilibration times. The Heat Management feature on the Mastersizer 3000+ eliminates these artifacts, enhancing result reliability and expedited equilibration times.

Tackling Thermal Artifacts in Dispersants

For over a decade, the Mastersizer 3000 has been the cornerstone tool for particle size analysis, establishing itself as the market's most accurate and robust particle-sizing system. It is also compact, with the laser module, flow path, sample chamber, and detector packed into a small space.

With its widespread adoption, some have encountered thermal artifacts in their samples, prompting a thorough investigation into the root cause.

Malvern Panalytical’s investigation revealed that mixing the dispersant liquid at slightly different temperatures may occur in the dispersion cell when employing dispersants like isopropanol, hexane, and isooctane. The resultant density differences can induce Rayleigh–Taylor instabilities, forming transient structures in the dispersant that mimic the light-scattering behavior of large particles.

As expected, this issue only affected customers using particular dispersants. Malvern Panalytical also discovered that extending the dispersant equilibration time could mitigate its occurrence. However, they wanted to ensure that all customers, regardless of their choice of dispersant, could swiftly generate high-quality data while minimizing the need for troubleshooting and its attendant challenges. Motivated by this objective, Malvern Panalytical developed the Heat Management feature for the new Mastersizer 3000+.

About the Mastersizer 3000+

Since its launch in 2012, the Mastersizer 3000 laser diffraction system has garnered a reputation as a compact, versatile, and high-performance instrument for acquiring particle size distributions.

Its applications span a wide range, from assessing powder flowability and packing to understanding drug dissolution rates, monitoring food emulsion stability, and ensuring the optical performance of paints. As a result, the Mastersizer 3000 has emerged as an invaluable asset across research and development (R&D) and manufacturing sectors.

This success owes much to both the hardware and software components. Over the years, alongside numerous features and accessories, Malvern Panalytical has released two software modules benefiting all Malvern instruments: Smart Manager, optimizing uptime and usage, and OmniTrust, ensuring regulatory compliance and data integrity.

Continuing this legacy, the Mastersizer 3000+, launched in March 2024, introduces three added software features, plus Heat Management, to enhance your particle-sizing capabilities and inform your critical decision-making:

- Size Sure for improved confidence in routine measurements and method development

- Data Quality Guidance for helping users make independent decisions on real-world samples

- SOP Architect for standardized, streamlined method development

When coupled with the instrument’s flexibility and ease of use, the Mastersizer 3000+ emerges as the ultimate solution for particle sizing needs.

Heat Management on the Mastersizer 3000+

In the Mastersizer 3000+, Malvern Panalytical has effectively addressed the issue of thermal artifacts by implementing minor modifications to facilitate rapid equilibration of the dispersant to ambient temperature.

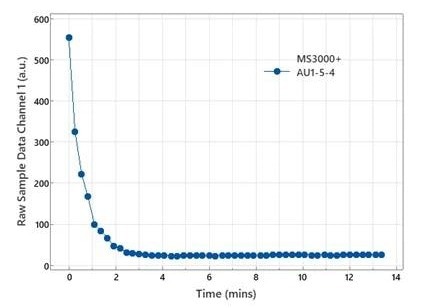

This solution’s effectiveness is demonstrated in Figure 1, illustrating a consistent decline in the optical signal of the dispersant isopropanol on the Mastersizer 3000+, reaching equilibrium within a few minutes without any discernable thermal fluctuations. Consequently, users can confidently proceed with sample measurements after a relatively brief equilibration period without concerns about thermally induced artifacts affecting their results.

Figure 1. The time dependence of the light background on the Mastersizer 3000+ for isopropanol dispersant, showing a smooth decline to equilibrium values. To ensure the data is representative of thermal artifact signals, the data is taken from channel 1. Data acquisition begins 20 s after the pouring of the dispersant liquid (pre-alignment delay). Image Credit: Malvern Panalytical Ltd

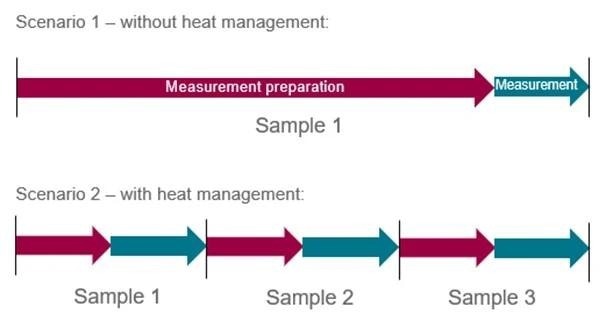

Based on our preliminary evaluation, Heat Management has demonstrated the potential to decrease equilibration time by up to 80% in scenarios where thermal artifacts were previously encountered (Figure 2).

Figure 2. Indication of the proportion of time that can be saved because of the Heat Management feature on Mastersizer 3000+. Image Credit: Malvern Panalytical Ltd

It is important to highlight that if you are currently using Mastersizer 3000, transitioning to the Mastersizer 3000+ guarantees continuity in your methods without necessitating any adjustments. You can anticipate performance that is at least equivalent. For those new to the Mastersizer range, you can look forward to the high performance typical of a Malvern Panalytical instrument and have confidence in your measurements, whatever dispersants you are working with.

Conclusion

By ensuring that the temperature of the sample is kept as near ambient as possible, the Heat Management feature on the Mastersizer 3000+ will help you to:

- Achieve superior results when working with troublesome dispersants, such as isopropanol, hexane, and isooctane

- Minimize thermal artifacts in your measurements

- Accelerate the thermal equilibration of samples

- Reduce time and expertise spent troubleshooting thermal issues

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical Ltd.

For more information on this source, please visit Malvern Panalytical Ltd.