SAF (sustainable aviation fuels, sometimes referred to as renewable jet fuels or biojets) have widely been accepted as the major contributor to the aviation industry’s global reduction of GHG emissions and decarbonization effort.

Large oil companies such as TotalEnergies, Neste, and World Energy have begun processing SAF over the last few years, and several others are putting resources into new biorefineries or altering existing facilities for the same purpose.

All SAFs are engineered to be drop-in jet fuels, meaning their chemical compositions are similar to those of conventional fossil-based jet fuels, removing the requirement to modify the aircraft engine or supply infrastructure.

That being said, the fact that the feedstock is non-conventional and frequently bio-based means that some additional requirements are needed to ensure that the fuels are strictly regulated and fit for purpose.

The HEFA (Hydroprocessed Esters & Fatty Acids) production route, as defined in ASTM D7566 Annex 2, is the overriding process utilized by current commercial-scale SAF producers. This process uses cracking, hydrogenation, and isomerization to transform waste oils, vegetable oils, and residue fats into jet-fuel-like molecules.

Another approved route is co-processing, defined in ASTM D1655 and Def Stan 91-091, where the raw bio-ingredients are processed with traditional crude oils.

When SAF is produced through the HEFA route, whether single or co-processed, the potential for unconverted esters and fatty acids can affect crucial parameters like thermal stability, low-temperature viscosity, or freezing point.

These parameters are mentioned explicitly as additional requirements in specifications such as D7566 Table A2.1, D1655 Table A1.1, or Def Stan 91-091 Table 3.

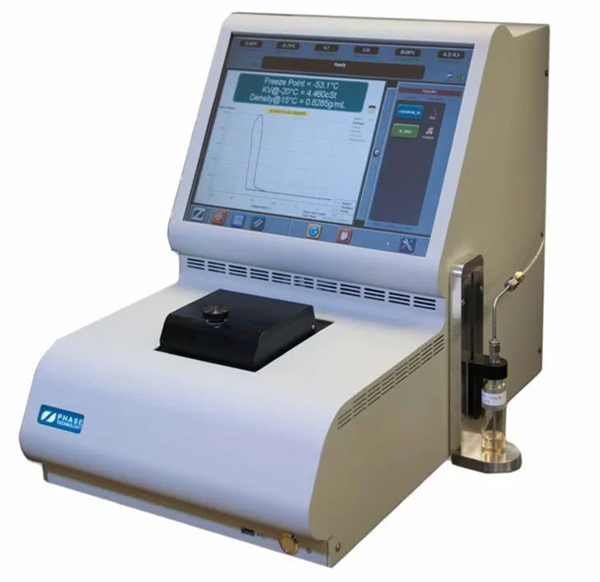

Phase Technology’s JFA-70Xi is a 3-in-1 analyzer that can measure three critical parameters: freezing point according to international test methods IP 435 / ASTM D5972, kinematic viscosity at both -20°C and -40°C according to ASTM D7945, and also density. This analyzer was specifically designed for the jet fuel industry.

Combined, these parameters define the low-temperature fluidity of jet fuels, which is crucial to safe aircraft operations. The instrument and its test methods have been approved in applicable global specifications of jet fuels (ASTM D1655 Table 1, ASTM D7566 Table 1, Def Stan 91-091 Annex E).

Image Credit: PAC L.P.

The main benefit of the JFA-70Xi lies in its capacity to accurately assess three vital parameters in as little as 15 minutes with best-in-class precision. of the JFA-70Xi lies in its capacity to accurately assess three vital parameters.

This method is particularly valued in the co-processing of SAF, serving as the preferred approach to guarantee that the freezing point remains unaffected by any residual unconverted materials (refer to D1655-20c Table A1.1 note H; or Def Stan 91-091 Issue 14 Table 3 Note 5).

For the required viscosity testing at both -20 °C and -40 °C of SAF, the ASTM D7945 method is an approved alternate viscosity test method in all of ASTM D1655, ASTM D7566, and Def Stan 91-091 global jet fuel specifications.

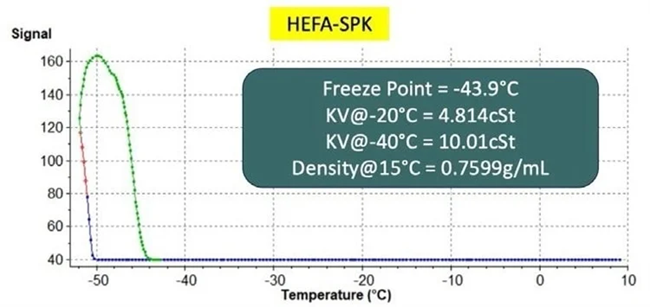

An additional benefit of the JFA-70Xi is its ability to produce a phase plot for each test, illustrating the changes in temperature versus optical signal throughout the cooling and warming phases. This feature enables operators to detect any unusual patterns or anomalies during the testing process. An example is shown in the graph below, which highlights an SAF sample that was created using the HEFA-SPK method.

Image Credit: PAC L.P.

This information has been sourced, reviewed and adapted from materials provided by PAC L.P.

For more information on this source, please visit PAC L.P.