Differences or variations in chemical composition or impurities in electrode materials can significantly impact a battery’s final performance. Therefore, running chemical composition and elemental impurity analysis is crucial as part of the battery manufacturing process.

Image Credit: JLStock/Shutterstock.com

Inductively coupled plasma (ICP) analysis is among the most commonly used tools, yet it is not always the best method. This is because sample digestion and frequent calibration are necessary throughout the process, which makes ICP inefficient and expensive for most elemental analysis needs.

To streamline elemental composition analysis and simplify detecting impurities down to the ppm level, Malvern Panalytical offers X-Ray fluorescence (XRF) solutions. These solutions eliminate sample digestion and the need to frequently calibrate, making them more cost-effective—up to three times cheaper per sample.

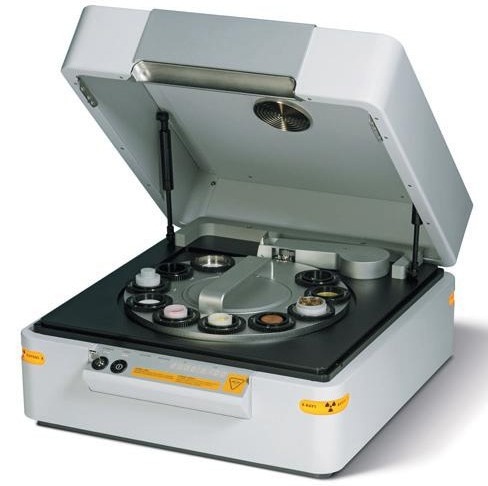

X-Ray fluorescence, in particular, produces more reliable measurements when running chemical composition analysis of cathode materials at low-percentage elemental levels. Specifically, in just a few minutes, Malvern Panalytical’s Epsilon 4 benchtop energy dispersive XRF spectrometer can accurately measure elemental composition.

When the goal is to achieve better light element sensitivity, Malvern Panalytical’s Zetium wavelength dispersive XRF spectrometer is recommended. These solutions allow manufacturers to reduce costs and optimize the use of human resources while saving ICP for very low-level impurity detection.

Image Credit: Malvern Panalytical Ltd

Composition and impurities analysis on five samples of LiFexMn1-xPO4 measured on the Epsilon 4 is shown in the table below. Measured Mn composition shows a straight-line

calibration with Target Mn composition in these samples. Source: Malvern Panalytical Ltd

| Sample |

Target Material |

Measured composition and impurities |

| |

|

Mn % |

Zr |

Al |

Ca |

Cl |

Co |

Cr |

Cu |

Ni |

S |

Si |

Ti |

Y |

Zn |

| SMP1 |

LiFe02Mn08PO4 |

80.2 |

0.11 |

0.011 |

0.014 |

0 |

0 |

0.017 |

0 |

0.026 |

0.008 |

0.022 |

0.009 |

0.006 |

0 |

| SMP2 |

LiFe04Mn06PO4 |

59.9 |

0.19 |

0.012 |

0 |

0 |

0.001 |

0.024 |

0.018 |

0.013 |

0.004 |

0.02 |

0.01 |

0.009 |

0.006 |

| SMP3 |

LiFe06Mn04PO4 |

40.2 |

0.117 |

0.041 |

0 |

0 |

0.003 |

0.034 |

0.011 |

0.023 |

0.006 |

0.024 |

0 |

0.007 |

0.005 |

| SMP4 |

LiFe08Mn02PO4 |

20.4 |

0.161 |

0.008 |

0.014 |

0.037 |

0 |

0.042 |

0.009 |

0.015 |

0 |

0.02 |

0 |

0.006 |

0.006 |

| SMP5 |

LiFePO4 |

0.1 |

0.155 |

0.015 |

0 |

0 |

0 |

0.055 |

0.009 |

0.024 |

0.007 |

0.024 |

0 |

0.009 |

0.004 |

Ensuring More Accurate Analysis

Sample preparation is one of the main contributors for errors in elemental composition analysis. Often, preparation methods, such as pressed pellets (in XRF) or acid digestion (in ICP), are afflicted by mineralogical or particle size effects in metal samples, jeopardizing result accuracy.

To meet the demand for reliable sample preparation for XRF or ICP, Malvern Panalytical provides a high-performance fusion solution. Fusion requires the dissolution of a fully oxidized sample at high temperatures in an appropriate solvent (a flux) in a platinum, zirconium, or graphite crucible.

Image Credit: Malvern Panalytical Ltd

The melted mixture is agitated and transferred to a mold to produce a glass disk for XRF analysis. It can also be placed into a beaker to make a solution for Atomic Absorption Spectroscopy (AAS) or ICP analysis. Users can rely on Malvern Panalytical’s 40-plus years of expertise in designing and delivering fusion recipes for different kinds of complex samples.

Malvern also offers two fusion instruments: the powerful LeNeo instrument and TheOx advanced instrument.

LeNeo is well-suited for battery sample fusion. This automatic electric instrument can prepare glass disks for XRF analysis and borate and peroxide solutions for AA and ICP analysis.

One fusion position makes it extremely easy to use, ensuring operator safety and superior analytical performance in the laboratory while eliminating doubt and driving high-precision quality control. In applications where high sample throughput is required, TheOx advanced instrument, which comes equipped with six fusion positions, can be used.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical Ltd.

For more information on this source, please visit Malvern Panalytical Ltd.