There are many benefits to using bonding tapes rather than mechanical fasteners or liquid adhesives. Compared to fasteners, they are more straightforward to apply, remove the need to drill holes, and are less labor and cost-intensive. In comparison to liquid adhesives, the application process is cleaner, there is no mixing or further cleanup, and there is less waste. They typically also have a longer shelf life.

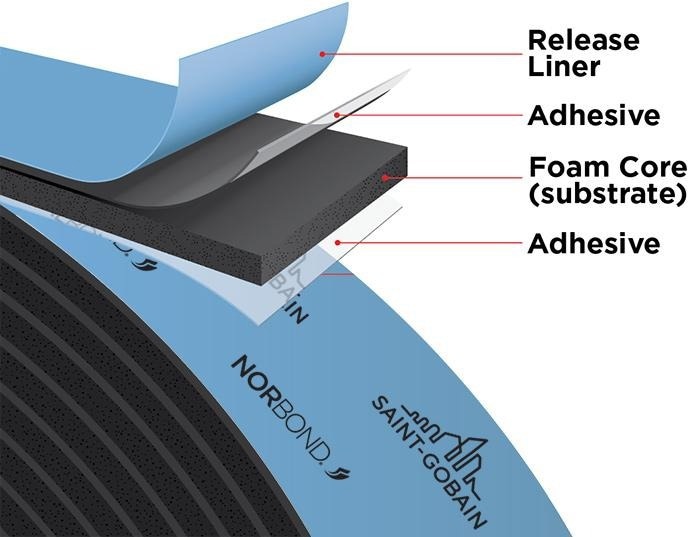

This article investigates the three key components of a bonding tape: liner, foam core, and adhesive. Read on to explore each component and their benefits in depth.

Image Credit: Saint-Gobain Tape Solutions

Liners

Liners are usually made of polyester, paper, polyethylene, or polypropylene. The selection of liner type depends on factors like the type of adhesive, the application needed, and the manufacturing process.

They are the protective layer that covers the adhesive side of the bonding tape. They act as the tape’s armor, protecting it from dirt, dust, moisture, or other contaminants.

Liners are specifically designed for easy release from adhesives. This enables convenient handling of the tape and allows workers to align and position the tape accurately before peeling off the liner and revealing the adhesive side to allow the bond to be formed.

Liners made of polyethylene and polypropylene are available in low to medium densities. These varietals can be advantageous for particular application needs. For example, low-density liners are preferred for applications involving corners, as lower density also means greater flexibility and release.

Foam Core

It is uncommon to discuss the specific adhesive type of a bonding tape but rather focus on the base foam core material—for example, polyethylene, polyurethane, or acrylic.

The selection of material depends on the surfaces to be joined, the required bonding strength, or the environmental conditions to withstand.

Generally, the foam core is considered the backbone of the bonding tape because it provides structural support. It enables tapes to absorb vibrations, shocks, and thermal expansion, contributing to the bonded assembly's overall longevity. This is important in automotive, aerospace, and electronic industries because materials are typically exposed to stresses and strains over time.

The Adhesive

In regards to adhesion, the focus is on the ability to bond or stick to a substrate. The adhesive has unique characteristics on a bonding tape that enable it to join with other materials. The particular application requirements typically determine the type of adhesive to be used, such as acrylic, silicone, or rubber, as each has individual properties. Acrylic adhesives, for example, have high-performance characteristics like temperature stability and exceptional UV resistance, which makes them well-suited for indoor and outdoor applications.

A main benefit of adhesive bonding is the ability to evenly distribute stress over the whole bond area. This minimizes the risk of localized stress points, which often can happen with conventional mechanical fasteners. The result is better aesthetics and a cleaner appearance.

Modern and Reliable Solutions

Bonding tapes are efficient and reliable options that meet the challenges that conventional methods like bolts, screws, and rivets cannot. They offer a versatile alternative for a robust, durable, and attractive method to join materials while removing issues like labor-intensive installation or corrosion. The liner, foam core, and adhesive are three main components that balance to enhance the bonding tape's structural integrity, efficiency, and aesthetics.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.