Could you please introduce yourself and tell us about your role at Kyocera?

Shinobu Nagata: My name is Shinobu Nagata; I am a senior design engineer at Kyocera. I help to design a variety of ceramic components for different applications.

Juan Pacheco: My name is Juan Pacheco; I am a senior regional sales manager for our Fine Ceramics Group for the Western region of Kyocera International Inc.

Taylor Aube: Hi, my name is Taylor, and I am the marketing communications manager at Kyocera International Inc. Fine Ceramics Group. In my role, I support our senior level management and I work with production and engineering on various different marketing campaigns and business development.

Can you give us a brief overview of Kyocera's overall product range and mission as a company?

Taylor Aube: Kyocera is a big company, we have a lot of different product lines. I am working with the Fine Ceramics Group, but Kyocera also does ceramic packaging for semiconductor components, LCD displays, automotive, and consumer product goods like knives and cell phones.

Kyocera was founded as a material science engineering company in Kyoto, Japan, in 1959 by Dr. Kazuo Inamori, and so Fine Ceramics is really the backbone of Kyocera. Kyocera's mission statement is, "Do what is right as a human being," and you can really see that come to life in the various technologies that we enable that enhance humans and the natural world.

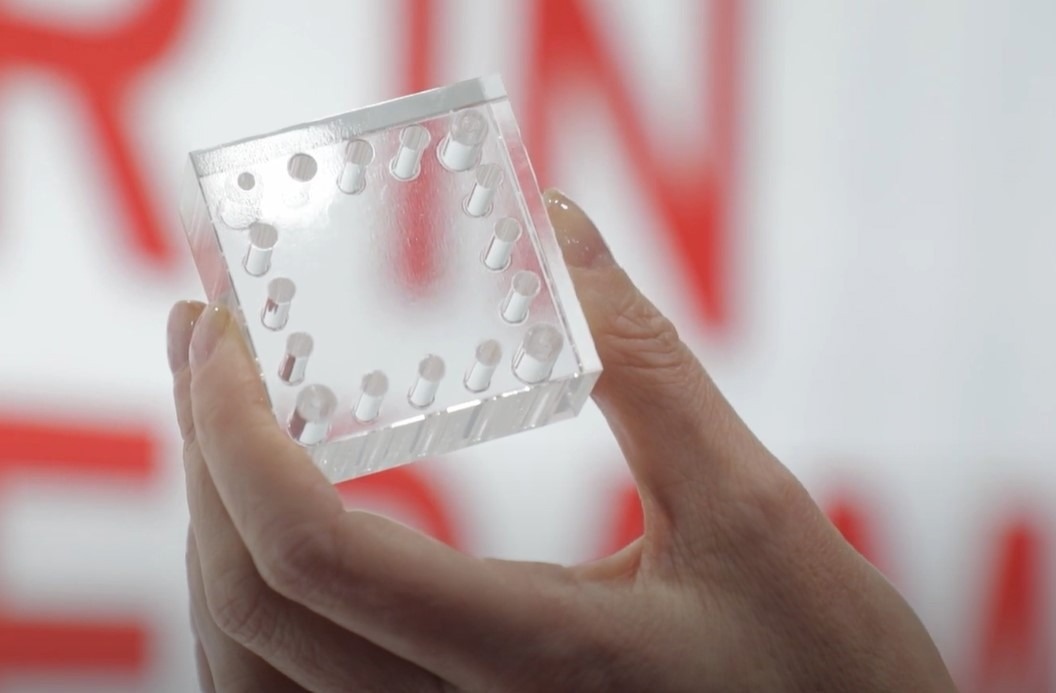

Kyocera's Single-Crystal Sapphire displayed at Pittcon 2024.

How does sapphire fit into Kyocera's mission, and what makes it something that you are excited about?

Taylor Aube: Sapphire is my favorite material that we offer because of its wide use and applications. It has really wonderful mechanical characteristics, which make it really good for a lot of different end-use applications, like mass spectrometry, RF windows, quantum computing, and more.

What are some of the mechanical traits that make Sapphire such a unique material to work with?

Shinobu Nagata: Sapphire is one of the few transparent ceramics we handle. It has a relatively higher mechanical characteristic, meaning we can process the material as thin as 30 microns because of this and its robustness.

Taylor Aube: What makes Sapphire a really unique and one of the best advanced ceramic materials out there is that sapphire is a pure form of alumina. Our single-crystal sapphire is grown in a lab using a variety of different methods. Through this forming method, we can achieve any axis, which gives us custom control over the different shapes.

Kyocera's Single-Crystal Sapphire displayed at Pittcon 2024.

How do Sapphire's properties make it useful for components in analytical and life-science applications?

Shinobu Nagata: They are very much chemical resistant, so in life sciences, when scientists are handling all kinds of corrosive, then sapphire is a material that can handle those chemicals. Moreover, oftentimes, we can use sapphire in plasma resistance applications as well. In that respect, I think we can support many life science applications.

Can you further discuss the impact and benefits that the Sapphire products bring to the life science fields?

Juan Pacheco: Sapphire is a single crystal material, so it is grown. Because of this, it is essentially void-free, it is also clear material. In life sciences, smoothness is important, for example, it is important for pump applications and for metering products. For medical products, as an example, the high transmission of sapphire is important, and as it is also a very strong material and very scratch-resistant, it is basically second to diamond.

Moreover, if you imagine endoscopy products, where doctors might have to bang around even when trying to be gentle, the glass materials may scratch where a sapphire won't. Those are same of the benefits of the materials that we offer.

How does Kyocera's approach to developing and offering Sapphire products meet the changing needs of the analytical sector?

Juan Pacheco: Kyocera has strong materials development and a lot of sales and engineering involvement. We typically work with our customers directly as much as we can, and we try to get on the ground level by supporting them in their development. From a materials perspective, we are always developing new processes that we think will suit the market.

For example, typically, sapphire is a machine material, but we have also done processing with laser drilling and laser cutting, and we do bonding without adhesive. We continuously develop products that we think the market will accept, in addition to our engineering and sales support to drive that forward.

The Benefits of Single-Crystal Sapphire || An Interview with Kyocera at Pittcon 2024

Looking forward, what advancements or innovations in Sapphire technology can we expect to see from Kyocera? How do you envision these impacting the fields of analytical chemistry and life sciences?

Shinobu Nagata: We are working on a variety of processing methods with sapphire, as well as other material options. In addition to Sapphire crystals, we are also looking to develop crystals that can transmit a higher or shorter wavelength of light for better material characterization.

Juan Pacheco: Some of the advancements will be in miniaturizing. When we think of things like implantables or anything medical-related, going small is important in terms of, for example, metering applications, improving polishing, and improving tolerances to meet customers' requirements. Also, for certain applications, improving transmission is important, as well as different manufacturing process to add holes, channels, and other things that our customers might need. We are constantly working on improvements.

About Kyocera

The Kyocera Group is a diversified network of companies working together to create new value for businesses and consumers. Kyocera Industrial Ceramics Corporation, a core company of the Kyocera North American Group, is a leading manufacturer and provider of industrial, automotive and semiconductor processing related advanced ceramic components, cutting tool products, liquid crystal displays, thermal printheads, metallized assemblies and industrial lenses.

provider of industrial, automotive and semiconductor processing related advanced ceramic components, cutting tool products, liquid crystal displays, thermal printheads, metallized assemblies and industrial lenses.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.