The semiconductor fabrication industry, crucial in the modern digital era, is significantly hinged on the precision and purity of gases utilized in manufacturing processes. Ultra-high-purity gas mixing is pivotal in achieving high quality and performance for semiconductors. This article investigates the intricacies of ultra-high-purity gas mixing. It looks at the significance, challenges, and advancements while offering insights for professionals and enthusiasts.

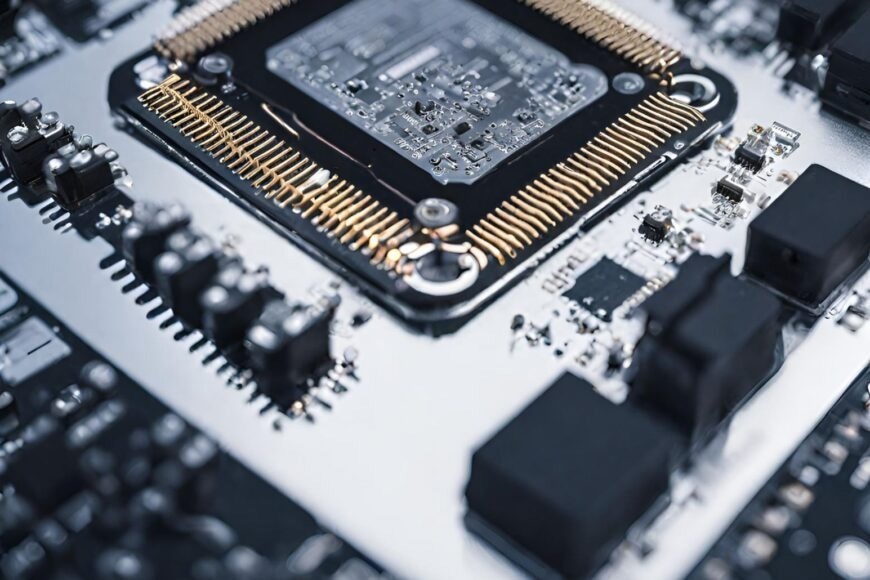

Image Credit: Environics, Inc

The Imperative of Purity in Gas Mixtures

- Criticality in Semiconductor Processes: Semiconductor manufacturing involves complex steps such as oxidation, dry etching, diffusion, and chemical vapor deposition, in addition to the plasma etching process. It also involves using thin films and creating silicon wafers or a single wafer.

Manufacturing processes also require the highest purity of gases. Impurities, even at parts-per-billion levels, can produce defects, affecting semiconductor devices' reliability and electrical properties.

- Composition Precision: Purity and the precise composition of gas mixtures are essential. The constituent gas ratio requires extreme accuracy to ensure consistent process conditions and product quality.

Challenges in Achieving Ultra-High Purity

- Contamination Sources: Contamination can be introduced from several places, including gas sources, handling, and delivery systems. Gas cylinders, valves, and piping material can also introduce impurities.

- Detection and Measurement: Detecting and measuring impurities at very low levels is challenging. Advanced analytical techniques, such as gas chromatography and mass spectrometry, are used for this purpose. Tools like mass flow controllers can be useful in avoiding contamination.

- Maintaining Purity in Delivery: Guaranteeing gas purity from the point of production to its use in the fabrication process is complicated. It requires specialized materials for transport and storage and state-of-the-art purification methods.

Technological Advancements

- Sophisticated Purification Technologies: Cryogenic distillation, membrane separation, and adsorption are utilized to reach the desired purity levels. Each technique has benefits and is selected based on the specific gas and impurities.

- Automated Control Systems: Automation is essential in maintaining the consistency and precision of gas mixtures. Advanced control systems enable real-time monitoring and adjustments, ensuring ideal mixture ratios and flow rates.

- Materials Science Innovations: Developing materials that react less and shed fewer particles has been an important advancement. These materials are used to construct storage and transport systems, reducing contamination risk.

The Impact of Ultra-High Purity Gas Mixing on Semiconductor Quality

- Enhanced Device Performance: Utilizing ultra-high-purity gases means fewer defects and higher-quality semiconductors. The result is higher yields, improved performance, and greater device reliability.

- Enabling Advanced Technologies: Precision control of gas mixtures is crucial in fabricating advanced semiconductor devices, like those needed in quantum computing and next-generation integrated circuits and their electric circuit patterns.

Future Directions for Semiconductor Fabrication

The semiconductor industry is constantly evolving, increasing the demand for ever-higher purity levels and more precise gas mixtures, particularly from those employed in fabrication plants.

Future developments will likely focus on:

- Nanotechnology in Purification: Nanotechnology can offer greater efficiency in purification methods and target specific impurities at a molecular level.

- AI and Machine Learning: AI and machine learning can help with the real-time optimization of gas mixtures and the predictive maintenance of gas delivery systems.

- Sustainable Practices: Environmental concerns are growing, making the development of sustainable and eco-friendly gas production and purification methods more prominent.

Discover Ultra High Purity Gas Mixing Solutions with Environics

Ultra-high purity gas mixing is essential to semiconductor fabrication, which requires fastidious attention to detail, continuous innovation, and advanced technology.

As the industry grows, developing more sophisticated gas mixing techniques will be important for meeting the evolving requirements of semiconductor technology. Whether seeking to produce a printed circuit board or new chip designs, semiconductor technology will continue to evolve. Ultra-high-purity gas mixing solutions will be needed to enhance quality.

Precision is paramount in semiconductor fabrication. Environics is at the forefront of this world with the advanced S4020 Ultra High Purity Gas Mixing and Diluting System. This state-of-the-art technology has been designed to meet the strict demands of ultra-high-purity gas mixing, ensuring the highest levels of purity and accuracy.

The Environics S4020 can revolutionize the fabrication process through unparalleled control and consistency.

References

State of the U.S. Semiconductor Industry 2023. Semiconductor Industry Association (SIA). https://www.semiconductors.org/2023-state-of-the-u-s-semiconductor-industry/. 2023. Accessed 19th January 2024.

This information has been sourced, reviewed, and adapted from materials provided by Environics, Inc.

For more information on this source, please visit Environics, Inc.