Sponsored by PerkinElmerReviewed by Olivia FrostJun 20 2024

Simultaneous thermal analysis, or STA, is a combination of differential thermal analysis and thermogravimetric analysis. It offers a wide array of information regarding polymeric materials. STA can provide essential insights into a data-driven approach to polymer processing and recycling by including thermal degradation profiles and direct quantification of inorganic fillers.

Image Credit: Shutterstock/Matveev Aleksandr

This article will demonstrate how STA provides a powerful yet incredibly simple method for determining fillers and detecting differences between polymeric materials. These differences can arise from variations in processing and the presence of additives.

The PerkinElmer Pyris™ STA 9 offers a powerful and flexible solution for obtaining valuable data for both research and routine applications. When used with PerkinElmer Pyris™ software, the STA 9 enables users to directly determine the filler content of polymeric materials, as well as other crucial parameters such as melting points and decomposition temperatures, without the need for calibration curves.

Thermal analysis of recycled materials is of paramount importance due to the necessity of understanding thermal transitions, such as melting points and filler content, which can significantly impact downstream processes.

Experimental

Flakes of polyethylene (PE) were measured as received, with no further sample preparation, using the PerkinElmer STA 9 (Figure 1) and 180 μL alumina crucibles (N5200040).

A key benefit of the STA 9 is its ability to rapidly determine the key thermal characteristics of a polymer without the need for sample preparation, treatment, or calibration curves. Sample measurements were carried out under a 20 mL/minute nitrogen purge using the following temperature program:

- Hold at 25 °C for one minute

- Heat from 25 to 750°C at 20 °C/minute

- Sample purge swapped from nitrogen to oxygen at 20 mL min-1 at 750 °C

- Heat from 750 to 850 °C at 20 °C/minute

These steps enable the determination of these recycled polymer sample properties:

- Melting point and enthalpy of fusion

- Boiling point of volatile additives

- Carbon black content

- Inorganic filler content

The STA 9 can also be enhanced by linking it to an FT-IR spectrometer or GC/MS, enabling the analysis of gases evolved during pyrolysis. This allows for further insights into the material’s composition and properties.

Results

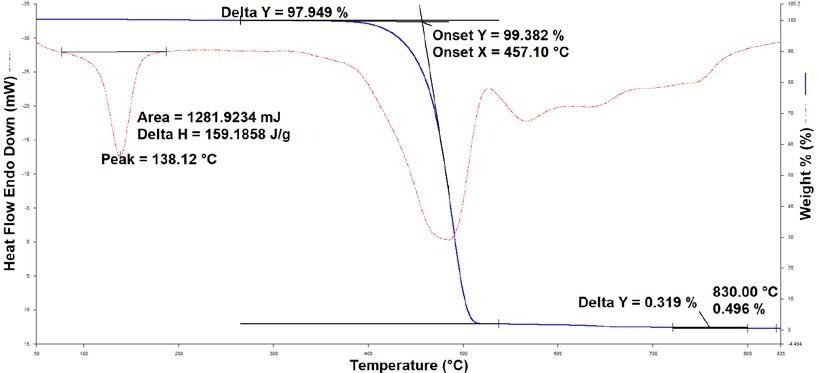

STA analysis results for a representative sample of recycled polyethylene are shown in Figure 2. Key parameters of this recycled polymer were calculated using the functions available in PerkinElmer’s Pyris™ software. The results of these calculations are presented in Table 1.

Figure 1. PerkinElmer Pyris STA 9 Simultaneous Thermal Analyzer. Image Credit: PerkinElmer

Figure 2. STA data from a recycled polyethylene sample. Image Credit: PerkinElmer

Table 1. Thermal Analysis Results from the recycled polyethylene sample. Source: PerkinElmer

| Parameter |

Value |

| Melting Point (Peak) |

138.12 oC |

| Degradation Temperature (Onset) |

457.10 oC |

| Carbon/Carbon Black Content |

0.319% |

| Filler Content |

0.496% |

Additional recycled polymers, and virgin LDPE were also measured. These results are seen in Table 2.

Table 2. Thermal Analysis Results from a further recycled and virgin polyethylene samples. Source: PerkinElmer

| Sample |

Melting

Point

(oC) |

Degradation

Temperature

(oC) |

Carbon/Carbon

Black

(%) |

Filler

Content

(%) |

| Recycled PE |

140.20 |

463.85 |

1.03 |

0.52 |

| LDPE |

118.59 |

459.58 |

0 |

0 |

| HDPE |

140.87 |

465.56 |

0 |

0 |

This data demonstrates a close relationship between the melting points and degradation temperatures of the recycled polymers and those of HDPE rather than LDPE. This indicates that the recycled polymers are polyethylene with a higher density and should be processed accordingly. Additionally, this analysis uncovers valuable information about the specific thermal properties of each material.

Summary

The PerkinElmer STA 9 offers a high-performance solution for the analysis of recycled polymers, enabling the determination of key parameters such as melting point, degradation temperature, and the quantification of filler and carbon black.

The Pyris software includes a variety of user-friendly data analysis tools that facilitate the determination of thermal transitions, such as onsets, peak area, peak height, and weight change.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.