The aerospace market has relied on Technetics’ Qualiseal® Non-contacting Lift Off Seals for decades, recognizing their performance and versatility since the 1990s. With extensive experience in designing custom-engineered, non-contacting sealing solutions, Technetics now applies this expertise to meet the demanding performance, space, and weight requirements of centrifugal industrial applications.

How Non-Contacting Seal Technology Works

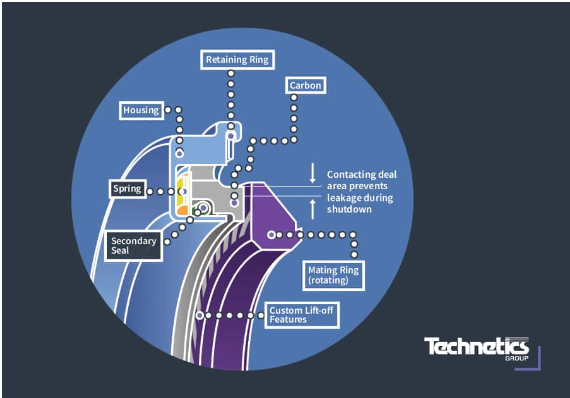

The seals are able to function within the non-contacting regime as they are enhanced to alter the primary seal interface lubrication.

Technetics has developed custom features on the face of the mating ring. As the ring spins, these features channel fluid (such as air or another gas) into a narrowing gap on the sealing face, increasing the pressure between the primary sealing components. This pressure causes the faces to move apart, allowing the part to operate in a non-contact mode.

The seal design also includes a static sealing dam to prevent leakage when the part is stationary. The pressure between the faces exceeds the system pressure, causing the mechanical face seal to introduce air into the system rather than letting fluid escape. The seal design also includes a static sealing dam to prevent leakage when the part is stationary. This design results in lower friction and higher surface speeds.

Image Credit: Technetics Group

Why Use Non-Contacting Sealing Technology?

Non-contact rotating seals provide many benefits, such as:

- Better performance with a greater life expectancy

- Fits into the same space as a conventional contacting seal

- Little to no wear

- Potential zero leakage

- Significant decrease in friction and heat generation

- Saved time and resources – no oil jetting, coatings, or particulate issues

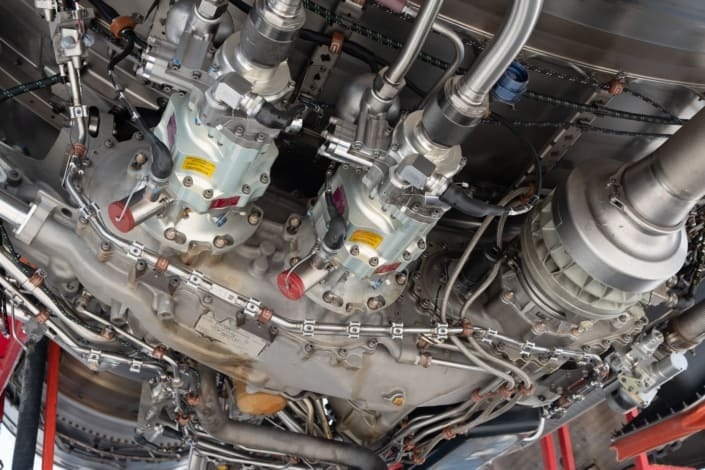

Condensing sealing solutions into compact and lightweight packages, ideal for the demanding conditions of the aerospace sector, is a common practice at Technetics.

With extensive expertise, Technetics effectively tackles complex industrial challenges. Aerospace applications, which typically operate at speeds between 15,000 and 80,000 RPM or 500 ft/second, fall well within Technetics' capability to meet stringent speed requirements for even the most demanding industrial applications.

Image Credit: Technetics Group

Choose Technetics Qualiseal® Mechanical Seals for an Aerospace Pedigree

Non-contacting technology addresses common issues found in standard face seals, and Technetics’ solutions offer improvements in efficiency, compactness, and lightweight design compared to competitors.

Reliability and performance are crucial in the aerospace industry, and Technetics applies the same rigorous standards to its industrial market products, supported by thousands of hours of test data.

Image Credit: Technetics Group

Whether replacing existing contacting mechanical face seals or designing new solutions, Technetics’ Qualiseal® Non-Contacting Technology delivers exceptional results.

Contact Technetics today to start exploring your industrial seal solutions.

This information has been sourced, reviewed and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.