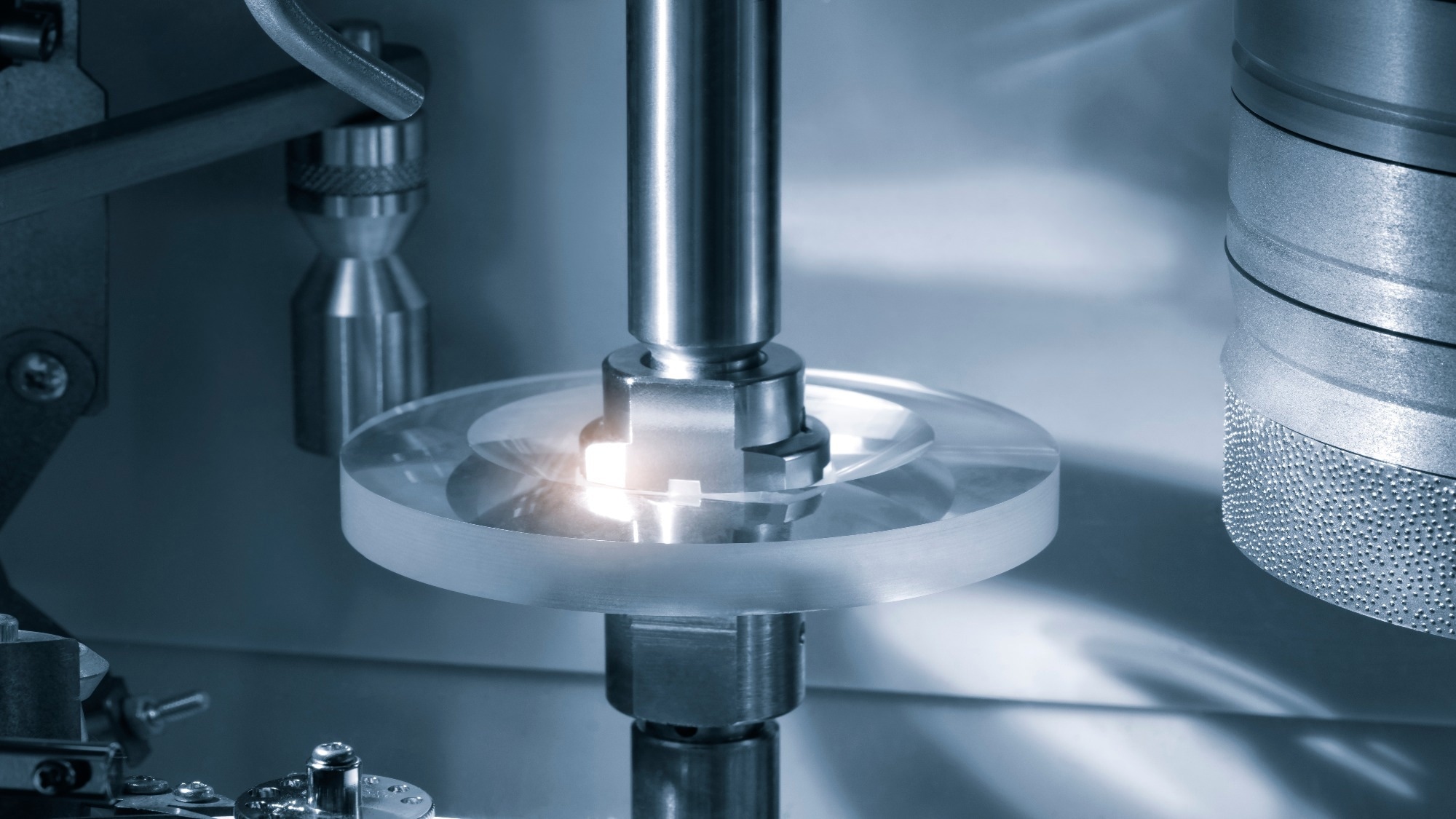

Optical processing, a key part of the precision manufacturing industry, involves transforming materials such as crystals, glass, and plastics into optical components, including prisms, lenses, and mirrors.

Image Credit: Matveev Aleksandr/Shutterstock.com

By using technologies such as laser processing, computer-controlled surfacing, ultra-precision polishing, and optical coating, the industry supports a variety of sectors, including semiconductor manufacturing, optical communications, consumer electronics, and biomedical devices.

The international optical and photonic components market reached over $300 billion in 2020.

Precision Manufacturing

Optical processing starts with raw materials and finishes with finely crafted optical components. The approach comprises cutting, grinding, fine grinding, polishing, and coating, and each stage aims to achieve rigorous dimensional and surface quality standards.

The process is vital for manufacturing components for optical instruments, fiber optics, camera lenses, and laser devices. The amalgamation of classic craftsmanship and contemporary automation technologies guarantees the precise control of light and enables precise imaging and transmission.

Advancement of Optical Processing Methods

The optical processing industry has advanced considerably from manual to highly automated and accurate techniques. Initially, optical components were manufactured by hand, which was laborious and had limited accuracy.

Mechanical methods were introduced in the early 20th century, improving consistency and productivity.

The advancements of CNC machines and laser technologies in the mid-20th and early 21st centuries allowed precision on the micron and nanometer level, significantly transforming the construction of optical components.

Such developments were guided by the growing demand for highly efficient and precise products across various industries, including consumer electronics and semiconductors.

Key Technologies

- Laser processing uses high-energy laser beams for precise cutting, welding, marking, and engraving of various materials, including metals and glass. The non-contact nature of laser processing is particularly advantageous for working with brittle materials and metals with high melting points, making it essential in the automotive, electronics, and aerospace industries.

- Ultra-precision polishing includes methods such as magnetic rheological finishing, which is vital for attaining smooth and precise surfaces, particularly on large or aspherical optical elements for astronomical telescopes or other advanced applications.

- Optical coating involves applying thin layers of material to optical components to enhance properties like transmission, reflection, and polarization. For example, anti-reflective coatings reduce surface reflections, improving clarity in cameras and eyeglasses.

- Computer-controlled optical surfacing integrates CAM, CAD, and precision machining to support the production of complex optical components with high surface quality, such as freeform mirrors and aspheric lenses.

Applications

- Semiconductor manufacturing: Optical processing is vital in photolithography and inspection procedures and is crucial for creating nanometer-scale circuits on silicon wafers.

- Consumer electronics: High-quality optics are vital in devices such as smartphones and AR/VR systems, where they enhance image capture and user experience.

- Optical communications: Precision optical components guarantee reliable and efficient data transmission in optical networks.

- Biomedical devices: Advanced optical processing is heavily reliant on the production of high-precision imaging equipment (including microscopes and diagnostic tools).

Current Trends and Future Directions

The optical processing industry is moving towards extreme precision and size diversity, from micron-scale structures to large-diameter mirrors. There is an increasing emphasis on the integration of shape precision with optical performance, especially in high-performance products such as diffractive optical elements and aspheric lenses.

The incorporation of processing and inspection technologies is becoming more widespread, guaranteeing that products meet rigorous quality standards in real time.

This information has been sourced, reviewed and adapted from materials provided by Shanghai Optics.

For more information on this source, please visit Shanghai Optics.