Image Credit: KLA Instruments™

Solar cell photovoltaic research, development, and manufacturing continue to rapidly move forward with new advances in solar texture and metallization manufacturing leading to higher efficiency solar cells at lower cost. KLA Instruments™, a division of KLA Corporation, has developed a portfolio of advanced metrology solutions tailored to the needs of solar cell manufacturing, including the Zeta™-20 and Zeta™-Solar optical profilers, the Tencor® P-7 stylus profiler, and the Filmetrics® R54 sheet resistance mapper.

Pyramid Texture Monitoring: Correlation of Zeta™-20HR to SEM

Fundamental to obtaining optimized electrical generation performance from a solar cell, the size and height of the textured light-absorbing surface must be measured, since the topographic properties of that textured surface directly control how well the solar cell absorbs sunlight. Responding to the solar industry’s roadmap request, KLA Instruments has expanded the Zeta-20 family of products to include the Zeta-20HR 3D Optical Profiler with improved resolution for the solar industry. The Zeta-20HR is designed to clearly see and measure modern texture that has smaller feature sizes than the less efficient solar cells of the past.

Zeta-20HR is a full solution for the solar industry. It leverages high optical resolution to quickly measure both the height and the lateral size of the solar cell texture. Those measurements can be made across the entire area of the solar cell, enabling factories to maintain cross wafer quality of the solar cell texture uniformity. KLA Instruments also designed the Zeta-20HR stage mechanics to be flexible; the Zeta-20HR has an integrated 230mm x 230mm XY stage that can support the latest large-sized cells of the present and future as well as hold multiple generations of legacy smaller solar cell formats that continue to be manufactured. The large sample size of the stage enables the uniformity of the texture properties to be measured across the surface of a solar cell – this is important for maintaining solar cell manufacturing quality.

SEMs have been proposed as a way to measure the texture of a solar cell. Although SEMs are good tools for measuring the lateral size of texture, they are not a full solution in the way that the Zeta-20HR is, for a number of reasons: SEM measurements are slow, expensive (particularly so for those that can accommodate the full size of the panel), and difficult and time-consuming to measure the height of the solar cell texture. Both height and lateral size metrology are needed by the solar industry. In contrast to the SEM, the Zeta-20HR integrates all the measurements of advanced texture needed by the solar industry.

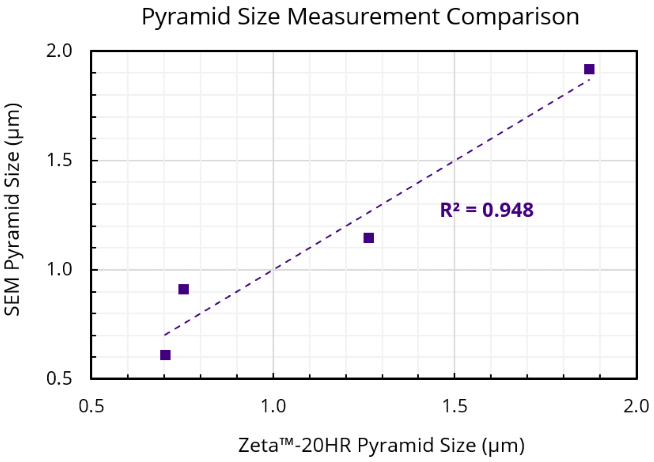

To illustrate the quality of the Zeta-20HR optical measurements, a measurement comparison of pyramid sizes was conducted using both SEM and Zeta-20HR. The measurement results show a strong linear size correlation, with a correlation coefficient of R2 = 0.948 for a set of various generation solar cells having texture ranging from 0.6 – 1.9µm in lateral size. The Zeta-20HR offers a fast and accurate means to characterize the lateral and height sizes of solar texture.

![The Zeta-20HR optical profiler measurements of lateral texture size correlate well to SEM images [images are 10 µm x 10 µm]](https://www.azom.com/images/Article_Images/ImageForArticle_23931_17249027898938347.png)

The Zeta-20HR optical profiler measurements of lateral texture size correlate well to SEM images [images are 10µm x 10µm]. Image Credit: KLA Instruments™

Solar texture lateral size measurements by SEM and Zeta-20HR show a correlation of R2 = 0.948. Image Credit: KLA Instruments™

Metallization Measurement Solution with the Zeta-Solar 3D Optical Profiler

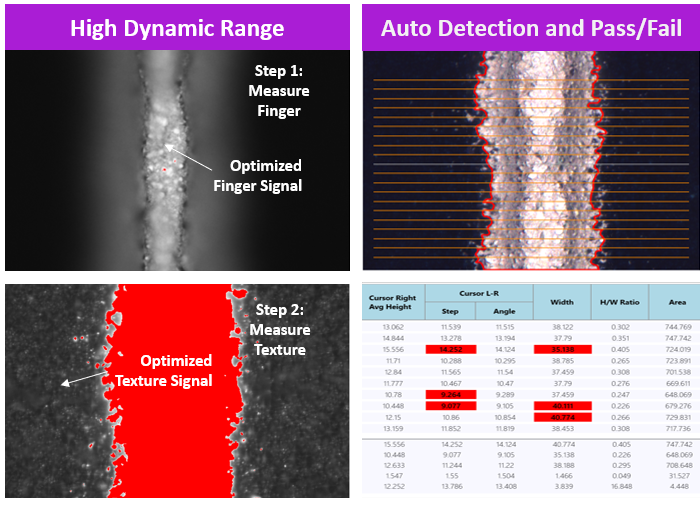

KLA Instruments has also recently introduced the Zeta-Solar optical profiler. The Zeta-Solar is designed specifically to measure the electrically conductive metallization features on solar cells. The back side of a solar cell has an array of metallic features called fingers, busbars and pads to conduct the solar-generated electrical energy away from the solar cell.

The metallization of advanced solar cells is rapidly evolving and new device designs are being introduced for solar cell manufacturing to both (1) reduce material costs and (2) increase the surface area for light capture - both advances decrease the manufacturing cost of solar cells. To reduce material costs, the electrically conducting metal lines are becoming thinner than for previous technologies. To further reduce material costs, the busbar, which is the intersection region where electrical signals from the fingers are combined, is being replaced by a compact silver pad. The Zeta-Solar optical profiler was designed for measurement characterization and quality control of Ag and Ag/Cu metallization lines and bond/contact pads of advanced solar cell technologies.

The Zeta-Solar optical profiler utilizes high dynamic range (HDR) capability to automatically detect and measure highly-reflective metallic lines on the very low reflectivity textured surface. Statistical and Pass/Fail data are automatically generated. Image Credit: KLA Instruments™

Silver Pad Solution with the Zeta-Solar Optical Profiler

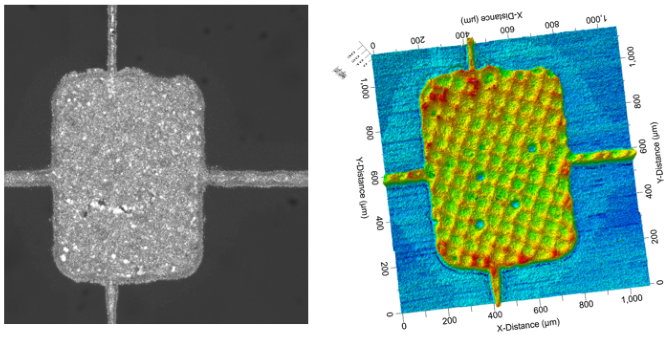

An example of an advanced pad feature is the 1 mm2-sized silver pad illustrated below. The pad was measured by the Zeta-Solar by automatically stitching multiple region measurements for analysis of the entire pad. These modern solar cells have extremely low reflective texture regions surrounding the metallization. Zeta-Solar leverages High Dynamic Range (HDR) to measure those narrower metal lines against the very low reflectivity textured surface.

Silver pad measured by the Zeta-Solar optical profiler. The Zeta-Solar automatically measures pad and line dimensions to enable process monitoring.

Image Credit: KLA Instruments™

Additional Solar Metrology Solutions from KLA Instruments.

The Filmetrics R54 sheet resistance mapper is used for silicon solar cell sheet resistance measurement. KLA’s leading sheet resistance technology delivers critical data not just for solar applications, but also for diffusion, oxidation and annealing process monitoring. The R54 four-point probe (4PP) technology is a semiconductor industry standard that delivers excellent short-term repeatability and outstanding long-term stability.

The trend in solar technology to maximize efficiency is to combine Si and thin film cell processes. A perovskite solar and Tandem - heterojunction technology (HJT) + perovskite - structure increases efficiency substantially. As this technology matures, it will displace other process steps and require additional monitoring for thin film step height. For nm- and Å-level film thickness monitoring for perovskite and Tandem solar cells, the Tencor® P-7 stylus profiler delivers accurate, repeatable results.

Summary and Outlook

In 2023, solar cell technology was largely dominated by TOPCon devices, whereas HJT and Tandem devices saw growth in 2024 and continue to grow through 2025. For new solar cell technology development in TOPCon solar cells, key measurement points are texture pyramid control using the Zeta-20HR optical profiler, post-diffusion monitoring using the R-series sheet resistance mappers, and metallization monitoring using the Zeta-Solar. For HJT devices, Zeta-20HR is used for texture monitoring and Zeta-Solar for electrode printing. For Tandem technology devices, thin film thickness monitoring is done using the P-series stylus profiler.

- The Zeta™-20HR optical profiler is designed for distinguishing the size and height of the pyramid structure in the 0.6 – 2.0µm range.

- The Zeta™-Solar optical profiler is optimized for solar PV metallization metrology and metallization quality control to less than 1% SD.

- The Filmetrics® R54 4-Point Probe measures 0.1 % σ monitoring multiple process quality steps even after more than 150,000 measurements.

- The Tencor® stylus profiler is capable of measuring nm-scale film thickness on perovskite solar cells with Å-level Z resolution.

The KLA Instruments suite of solar cell metrology tools meets the industry requirements to drive innovation for both current and next-generation manufacturing processes. More detailed information about stylus profiler and sheet resistance measurement use cases in solar cell production is available directly from KLA Instruments.

This information has been sourced, reviewed and adapted from materials provided by KLA Instruments™.

For more information on this source, please visit KLA Instruments™.