Inspecting food for foreign materials is a crucial aspect of quality assurance for food companies. Technologies like metal detectors and X-ray scanners are commonly used to identify small debris embedded in food products. Once detected, accurately identifying the material of these foreign bodies is essential.

Pinpointing the root cause of contamination is crucial to preventing it from moving further down the processing lines, which could lead to costly product recalls. Common types of debris include clear plastics used for shipping food items, various polymers and plastics found in manufacturing (e.g., gaskets), glass or silicates, metals from processing equipment, and materials introduced from outside the manufacturing facility.

The process of identifying unknown particulates begins with a visual inspection of the debris. Spectroscopic techniques, such as infrared (IR) and X-ray fluorescence (XRF), can provide rapid and accurate chemical identification of the debris.

These techniques facilitate the identification of the root cause of contamination, helping to prevent large-scale recalls and saving food manufacturers significant costs. Most importantly, identifying the root cause ensures safer food production for consumers.

This article highlights how Fourier transform infrared (FTIR) spectrometry and handheld X-ray fluorescence (HHXRF) spectrometry complement each other in the rapid chemical identification of various foreign materials in food, such as organics/plastics, rubber, ceramics, glass, and metals.

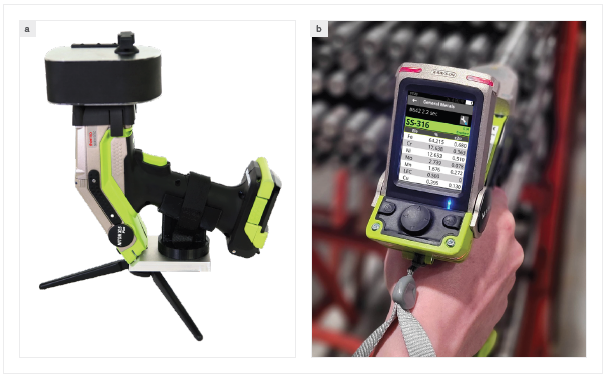

The FTIR analysis featured here was conducted using the Thermo Scientific™ Nicolet™ Summit™ X FTIR Spectrometer. The handheld XRF analysis was performed with the Thermo Scientific™ Niton™ XL5 Plus Handheld XRF Analyzer (Figure 1).

Figure 1. (left) Nicolet Summit X FTIR Spectrometer with a Thermo Scientific™ Everest™ diamond attenuated total reflectance (ATR) accessory; and (right) Niton XL5 Plus Handheld XRF Analyzer. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

The Nicolet Summit X spectrometer paired with the Everest diamond ATR system is a robust FTIR configuration that can be assembled on the factory floor, accelerating data acquisition times. ATR is the most frequently used data acquisition mode for material identification with the Nicolet Summit X spectrometer, requiring no sample preparation. A sample is simply positioned on top of an infrared inactive crystal, usually diamond, and a pressure tower is used to place the sample onto the crystal.

The pressure tower features a built-in slip clutch that regulates the torque applied, protecting the ATR accessory from damage. Thanks to the hardness and chemical inertness of diamond, tough, sharp, or rough materials like glass, as well as acidic or basic samples (pH 1-14), can be safely placed on the crystal without risk of damage.

Once the sample is secured, data acquisition begins, generating an infrared spectrum of the unknown material. Data acquisition for a single spectrum typically takes around 20 seconds. Once obtained, the spectrum can be compared against a database of commercial libraries containing known components for material identification.

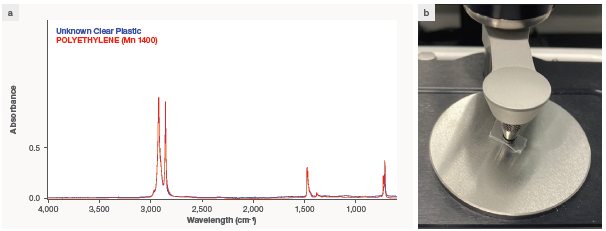

In the example presented in Figure 2, the analysis of an unknown clear plastic sample using the Nicolet Summit X spectrometer revealed that the material was polyethylene-based.

Users can also create their own spectral libraries from known materials within their production or work environments, which can be searched to identify materials and contaminants. Identifying the material helps trace the source of foreign debris—whether from within the plant or an external source—enabling targeted actions to prevent further contamination.

Figure 2. (a) Spectrum in Thermo Scientific™ OMNIC™ Paradigm software of unknown transparent plastic, overlayed with results of a library search, that generates a good match for polyethylene. (b) Example of a transparent plastic loaded onto the diamond ATR crystal for data acquisition. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

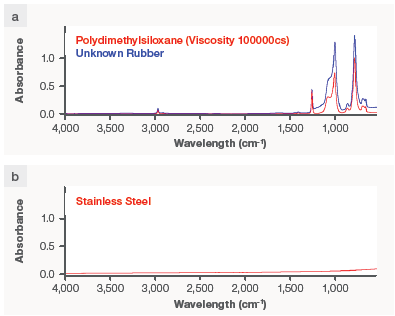

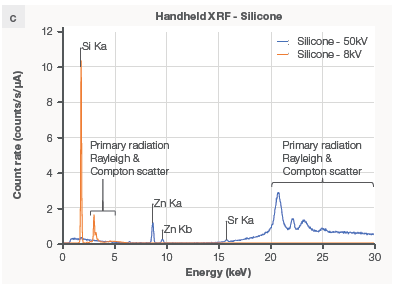

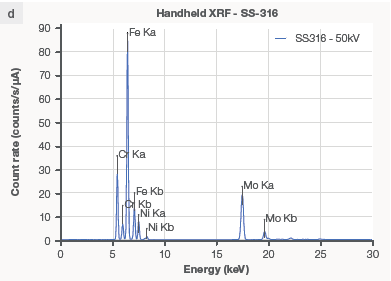

In another experiment, two different samples—one rubber and one metal—were analyzed using both the Nicolet Summit X FTIR spectrometer and the Niton XL5 Plus HHXRF analyzer, highlighting the complementary nature of these techniques (Figure 3).

For the rubber sample, the FTIR spectrometer produced a clear spectrum (Figure 3a, blue curve), which the software matched to a silicone-based rubber, specifically polydimethylsiloxane (PDMS) (Figure 3a, red curve). However, the FTIR analysis of the stainless-steel sample yielded no significant results, producing a flat line (Figure 3b), as metals do not interact with infrared light.

The Niton XL5 Plus analyzer is well-suited for identifying inorganic materials, especially metals and alloys like stainless steel 316 (Figure 3d). Although the HHXRF analyzer did not directly identify the rubber as silicone, it detected key elements like silicon (Figure 3c) and other metals in the sample.

A key example of how FTIR and XRF complement each other is in the identification of materials like soda-lime or borosilicate glass. While FTIR would produce a broad peak in the lower wavenumber region, making it difficult to identify the glass type, XRF can easily distinguish between these glasses based on their elemental composition, such as silicon and calcium.

FTIR excels at identifying organic-based materials but is unable to differentiate between metal alloys. In contrast, the handheld XRF analyzer is highly effective at distinguishing metal alloys, glasses, and minerals, though it provides less detailed information for polymer or rubber samples. Therefore, the combination of HHXRF and FTIR measurements allows for the comprehensive identification of a wide range of unknown materials.

Figure 3. FTIR and HHXRF data on the same plastic and metal samples. The FTIR instrument can produce a reading on (a) silicone rubber but not on (b) stainless steel. The HHXRF analyzer detects (c) silicone and zinc in the rubber sample without being able to identify the type of rubber, and it fully identifies (d) the metal sample as stainless steel 316 grade. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

The Niton XL5 Plus is a compact, lightweight handheld XRF analyzer weighing approximately 3 pounds. It can be used directly on the production floor or elsewhere in the plant. Modern HHXRF analyzers can detect and quantify elements with atomic numbers ranging from 12 (magnesium) to 92 (uranium) across various materials such as metals, alloys, ceramics, glass, minerals, and plastics.

HHXRF identifies substances by quantifying elements and comparing the sample's composition with tabulated reference values. This method, known as identification via grade table, helps identify metals by matching the measured composition with standardized values for over 500 alloys, including steel, stainless steel, and alloys of aluminum, copper, nickel, cobalt, titanium, tin, lead, and tungsten.

Another approach is identification via spectral fingerprints, where the spectrum of an unknown material is compared to known spectra. HHXRF analysis typically takes only a few seconds for metals and alloys and a few minutes for trace element analysis. The user can either point the analyzer at large samples and press the trigger or place smaller samples on a test stand (Figure 4a) for analysis. This fully nondestructive process provides results in real-time, displaying mass concentration data on the analyzer's LCD screen (Figure 4b).

While handheld XRF can analyze a wide range of foreign bodies found in foods, such as glass, ceramics, stones, bones, and plastics, it is particularly effective for metals. HHXRF can measure metal concentrations and identify the specific alloy grade.

The foreign body identification (FBI) workflow using HHXRF typically involves mapping and collecting data from all parts of the production line that could potentially cause contamination, starting with metal components and then moving to ceramic and glass parts. By comparing the composition of foreign debris found in food with the materials used in the processing line, users can efficiently trace the source of contamination.

This method is beneficial when different alloy grades are used, helping pinpoint whether the contamination came from within the plant or from an external source. For instance, debris from a stainless steel 316 sieve mesh can be easily distinguished from debris originating from a stainless steel 430 blade used in a frozen food block flaker.

Figure 4. (a) The Niton XL5 Plus Handheld XRF Analyzer with a sample loaded in test stand; (b) Live readout of stainless steel 316 and its elemental composition on the Niton XL5 Plus Analyzer. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

When the same type of material, for instance, stainless steel 316, is used at several locations in the production line, identification of foreign bodies made of this material via its composition or grade may not be able to locate the exact source of contamination due to a lack of specificity.

Another effective method is identification via spectral fingerprinting. In this approach, the user creates a library of spectra from measurements of both metallic and non-metallic materials collected during the mapping process.

Once the custom library is established, the spectral fingerprints of contaminant samples can be compared to the library entries or spectra from suspected sources, making it easier to trace and address the contamination source. If no match is found, there is a likelihood that the contaminants originated from the raw materials, suggesting that supplies should be thoroughly inspected before they enter the production process.

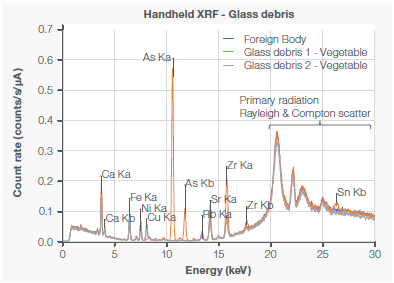

The use of custom spectral libraries proved valuable in a case where a single piece of glass was found in a processed food product. This prompted an investigation to trace the source of contamination. The production line was quickly ruled out as the cause. A thorough inspection of the raw vegetable materials then revealed additional glass debris.

As shown in Figure 5, the spectral fingerprint of one glass fragment (represented by the grey curve) closely matched that of the foreign body found in the food product (blue curve). However, the spectrum of another glass fragment (orange curve) was distinctly different, suggesting that the contamination in the vegetable raw materials came from multiple sources.

Beyond contaminant identification, HHXRF assists maintenance teams in food processing plants by verifying the material specifications of essential equipment parts, such as auger conveyors, cutting blades, frozen food block flaker blades, and mixing paddles. This ensures compliance and prevents equipment failure.

A notable example is the use of grade 304 stainless steel instead of grade 316 for a sieve mesh. Since grade 304 is less resistant to corrosion, it carries a higher risk of deterioration over time, potentially leading to equipment failure and contamination in salt-heavy foods like soups and sauces.

Figure 5. XRF spectra of a foreign body found in processed food and two pieces of glass debris subsequently detected in the vegetable used as raw materials. The foreign body (blue curve) has a similar spectral fingerprint to glass debris 2 (grey curve) but presents a noticeably different spectrum than glass debris 1 (orange curve) when looking at trace metals such as copper (Cu), arsenic (As), strontium (Sr), zirconium (Zr) or tin (Sn). Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

Conclusion

FTIR and handheld XRF spectrometry are easy-to-use, rapid analytical techniques offering significant value to food processing plants. In enhanced quality assurance programs, metal detectors and X-ray inspection systems can identify foreign materials, after which these analytical techniques optimize the user’s capacity to determine the origin of foreign body materials so corrective measures can be promptly implemented.

FTIR is ideal for distinguishing between various types of organic and polymer-based materials, while handheld XRF serves as a complementary tool for analyzing inorganic materials such as metals, glass, and ceramics. In addition to FBI, both techniques offer food manufacturers valuable data to validate quality claims or to challenge false contamination allegations.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.

For more information on this source, please visit Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.