Sponsored by Mo-SciReviewed by Louis CastelOct 3 2024

Glass and ceramics share similar material qualities, such as high strength and hardness. However, their structures differ significantly at the microscopic level, influencing their applicability for specific uses.

Transparent optical ceramic. Image Source: CILAS. Used under CC BY-SA 3.0 / Cropped from original.

Key Characteristics of Glass

Glass is a material distinguished by its amorphous or non-crystalline microscopic structure.1 Glasses are typically transparent to visible light, and many are valued for their chemical inertness and hardness, allowing them to endure highly corrosive environments such as severe pH levels and biological conditions.2

Crystalline materials, in contrast, have a great degree of regularity in their atomic structure, which includes a periodic crystal lattice. The planes of atoms in crystalline materials can easily glide past one another, reducing internal stresses.

This uniformity is absent in glasses, which contributes to their brittleness. The glass transition temperature—the temperature at which glass changes from a hard, brittle state to a molten one—is an important property of glass. This temperature has a considerable influence on the glass’ thermal characteristics and behavior.3

Glasses are commonly made up of network formers like SiO2, B2O3, and P2O5, as well as network modifiers intended to attain specific features. Minimizing undesired dopants in optical fibers is critical to preventing the creation of color centers and radiation damage. Dopants can, however, improve the optical and optoelectronic properties of glasses for use in other applications.4

Bioactive glasses form a different category, designed for medical equipment and technologies. These materials are physiologically safe and aid in the healing or therapy processes, often through ion release.5

Bioactive glasses—typically composed of SiO2, calcium oxide, sodium oxide, and phosphate (P2O5)—can be created with specific degradation kinetics to allow drug release or the creation of dissolvable scaffolds for wound healing.

Key Characteristics of a Ceramic

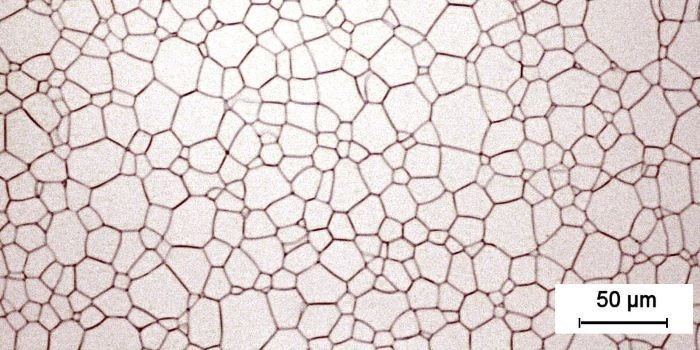

Ceramic materials are known for their extreme thermal resistance. They are part of a wide family that includes carbides, inorganic materials, metallic oxides, and nitrides. Ceramics’ microstructure is made up of small crystalline portions known as grains, which can vary in size.

Grain size and composition have a substantial impact on ceramic material qualities, and interfaces between these grains are critical for improving hardness and durability.7

Ceramics can be extremely fragile, with little resistance to shearing and tension pressures. However, like many glasses, they are highly resistant to chemical erosion.

With the right chemical composition, ceramics can be engineered into semiconductors and electrical components. Due to their excellent thermal and electrical resistance, ceramic materials are also used to make numerous capacitors.

Ceramics are now widely employed in many industries, and the development of composite ceramics has expanded their applications, notably in the medical profession, to create devices such as dental implants.8

Glass-Ceramics

While a wide range of glass and ceramic materials exist, the perfect material qualities for a certain application may need to combine their best features. Glass-ceramics are such a hybrid, with glass-like chemical compositions but a different microstructure.

Glass-ceramics, as opposed to purely glassy materials, are composed of a crystalline structure interleaved with amorphous features. This is often accomplished using a fine-grained microstructure that evenly distributes crystalline phases inside an amorphous glass matrix.

This hybrid microstructure makes glass-ceramics stronger than pure glass and allows them to maintain some of ceramics’ favorable electrical characteristics while staying transparent.9

Glass-ceramics are highly appreciated as bioactive materials, with versions such as Bioglass 4555 getting FDA certification for use in medical devices.

The capacity to adjust their properties during manufacture via controlled crystallization procedures increases their adaptability to difficult applications.

Nonmetallic materials, such as glass, ceramics, and glass-ceramics, have a wide range of properties that are determined by the degree of crystallinity in the microstructure.

In general, more crystallinity leads to tougher materials, but it can also increase light scattering, necessitating particular processing to make ceramic materials transparent.

Mo-Sci Solutions

Mo-Sci specializes in the research and production of glass, ceramic, and glass-ceramic materials for a wide range of applications.

Whether you require very high-purity silicon dioxide or a more complicated custom-made bioactive material, contact Mo-Sci now to see how its services and capabilities may help you find the ideal material solution for your product requirements.

References

- Doremus, R. H. (1972). Structure of inorganic glasses. Annual Review of Materials Science, 2(1), 93-120. https://doi.org/10.1146/annurev.ms.02.080172.000521

- Axinte, E. (2011). Glasses as engineering materials: A review. Materials & Design, 32(4), 1717-1732. https://doi.org/10.1016/j.matdes.2010.11.057

- Tanguy, A. (2021). Elasto-plastic behavior of amorphous materials: a brief review. Comptes Rendus. Physique, 22(S3), 117-133. https://doi.org/10.5802/crphys.49

- Griscom, D. L. (2013). A Minireview of the Natures of Radiation-Induced Point Defects in Pure and Doped Silica Glasses and Their Visible / Near-IR Absorption Bands, with Emphasis on Self-Trapped Holes and How They Can Be Controlled. Physics Research International, 379041. http://dx.doi.org/10.1155/2013/379041

- Jo, W., Kim, D., & Hwang, N. (2006). Effect of Interface Structure on the Microstructural Evolution of Ceramics. Journal of the American Ceramic Society, 8, 2369–2380. https://doi.org/10.1111/j.1551-2916.2006.01160.x

- Cannio, M., Bellucci, D., Roether, J. A., & Cannillo, V. (2021). Bioactive Glass Applications: A Literature Review of Human Clinical Trials. Materials, 14, 5440. https://doi.org/10.3390%2Fma14185440

- Jo, W., Kim, D., & Hwang, N. (2006). Effect of Interface Structure on the Microstructural Evolution of Ceramics. Journal of the American Ceramic Society, 8, 2369–2380. https://doi.org/10.1111/j.1551-2916.2006.01160.x

- Vallet-Regí, M. (2001). Ceramics for medical applications. Dalton Perspective, 97–108. https://doi.org/10.1039/b007852m

- So, M., Górny, A., Pisarska, J., & Pisarski, W. A. (2018). Electrical and optical properties of glasses and glass-ceramics. Journal of Non-Crystalline Solids, 498, 352–363. https://doi.org/10.1016/j.jnoncrysol.2018.03.033

This information has been sourced, reviewed, and adapted from materials provided by Mo-Sci.

For more information on this source, please visit Mo-Sci.