Battery Show keynote speaker John Warner discusses the future of batteries, including policies and how to electrify off-road vehicles.

The Battery Show and Electric & Hybrid Vehicle Technology Expo will be hosted at Huntington Place in Downtown Detroit on October 7-10, 2024. Join 19,000+ fellow peers at the largest advanced Battery and H/EV technology trade show in North America.

Can you start by giving us a brief overview of your role as Chief Customer Officer at American Battery Solutions (ABS) and how your experience has shaped your approach to the evolving battery industry?

As Chief Customer Officer, my role is to champion the customer throughout the entire value chain from first engagement to end of life. In this manner, I support our sales and marketing teams, along with our service and warranty teams. In this role, along with my various industry partners and events, I am also the voice of the customer when it comes to new product development in many cases. Where I bring feedback is what is happening in the industry with our prospective customers, what our competitors are doing, and what we can learn from them. The final part of this role is to build networks with the various industry and trade groups and technology companies in the ABS team.

I developed this role based on learning from other companies and industries. I have also spent 18 years in the automotive industry, 15 years in the battery industry, eight years in higher education, and over 10 years as an author. This role is about more than just generating revenue; it is about building relationships with our customers through mutual trust and support.

What policy shifts do you foresee having the most significant effect on the sector, and how is ABS preparing for such changes?

The world has gone through a long period of globalization, moving manufacturing to the lowest-cost nations. Today, however, we are seeing that manufacturing is a national strength that must be supported. This has led to national policies that support domestic manufacturing. This trend will continue around the globe, with the battery industry remaining at the center.

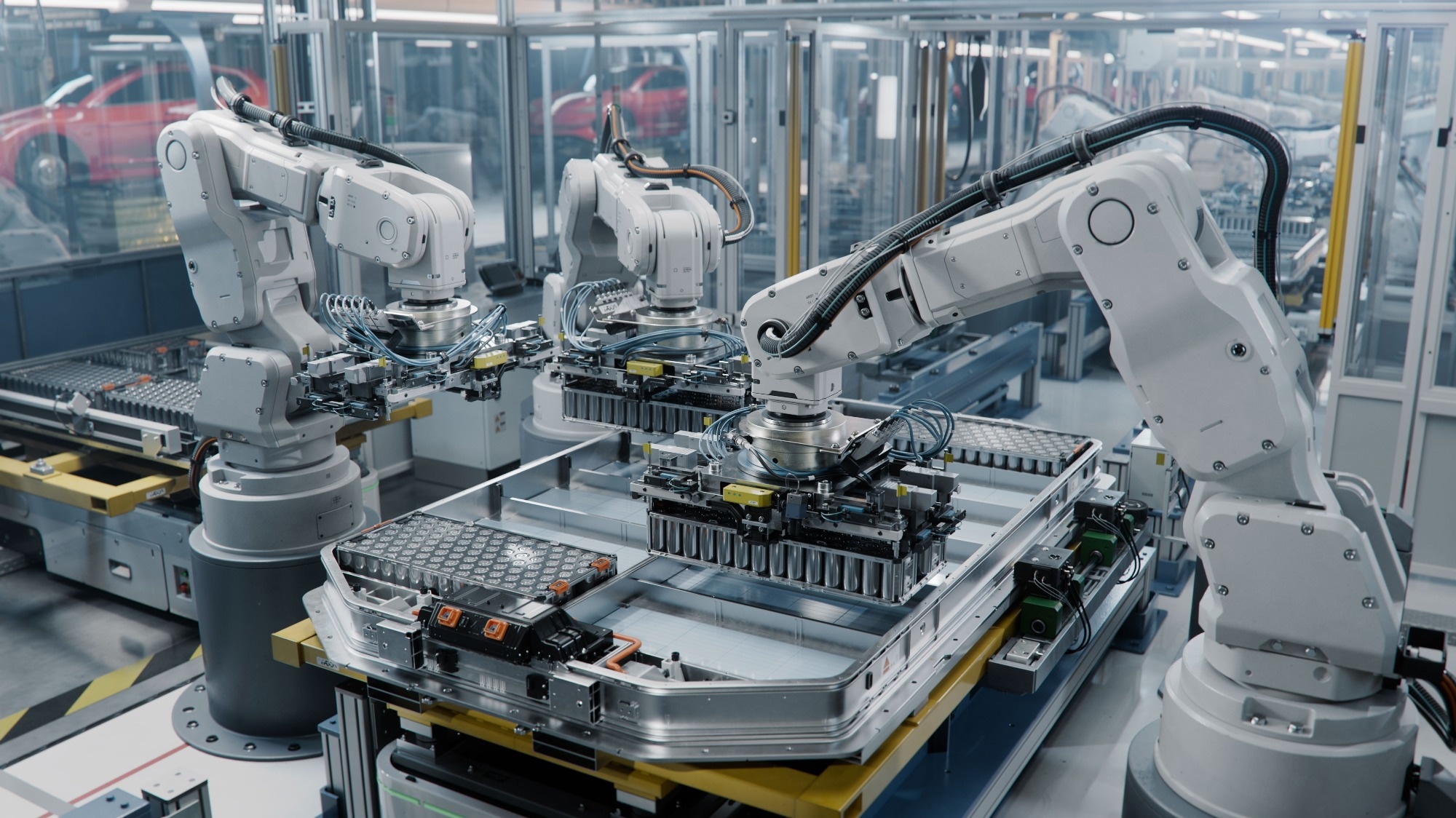

ABS started with the idea of being a domestic U.S. battery supplier. Today, we are ramping up a third shift in our Springboro, Ohio, manufacturing facility and will triple our capacity over the next 18 months.

Image Credit: IM Imagery/Shutterstock.com

What are some proactive strategies that industry leaders can employ to remain agile in the face of unpredictable policy changes?

I think the two most important things you can do are, firstly, to have a well-thought-out and clear strategy and secondly, to conduct regular scenario planning against that strategy to ensure you understand how you may need to flex or shift in the future.

The EV and battery industry is a great example here. With battery chemistries and form factors evolving so rapidly, it is often hard to predict what the chemistry or cell of the future will look like. Scenario planning will help you understand how to zig when the policies zag.

How do you see evolving environmental policies, such as decarbonization efforts, affecting the supply chain for batteries, particularly for critical materials like lithium and cobalt?

One industry that is moving quickly on decarbonization is the mining industry, with many mines now implementing a decarbonization strategy. We also see new technologies, such as direct lithium extraction, being launched, which can potentially reduce the time and energy needed to extract lithium from the ground.

The other impact of these policies is the localization of the processing, opening of new sources, and more global partnerships. For instance, one company just announced that they were breaking ground on a new anode material factory in my old hometown of Flint, Michigan. This has the effect of bringing the active anode material (AAM) processing right to our doorstep, which reduces the CO2 footprint of moving the AAM to the cell maker. Of course, we still need to find ways to reduce the CO2 footprint of getting the raw materials to the AAM and cathode active material plants, but that is improving as more of these domestic sources come online over the next 10 years.

Your second session focuses on electrifying off-road vehicles in the mining and construction sectors. What are some of the unique challenges associated with developing batteries for these heavy-duty applications compared to traditional electric vehicles?

First and foremost is safety. Safety is a sine qua non; in other words, it is not negotiable. Imagine having a battery fine in an underground mine - that is unacceptable, as it puts people’s lives at risk.

Next is scale, in two different senses. First, we often talk of economies of scale in the automotive industry, where we build nearly 17 million light-duty vehicles in the U.S. every year. However, in the mining and construction industries, they tend to sell hundreds of units per year. The second half of that scale question is in the sheer size; looking across a portfolio, we may find applications ranging from small 48 V with tens of kilowatt-hours (kWhs) of energy all the way up to 1,500 V systems with over a megawatt-hour of energy.

Next is the duty cycle. The typical light-duty consumer vehicle operates for under one hour per day, while the construction or mining vehicle may operate for 20–22 hours per day, six to seven days per week.

Mining and construction vehicles operate under extreme conditions. How does battery design need to adapt to meet the demands of durability, high energy density, and safety for off-road applications?

In addition to those mentioned above, infrastructure poses significant challenges to both the construction and mining industries. Construction sites are temporary sites with no installed infrastructure to support electric vehicle charging, so this must be brought in. Mines tend to be in very remote areas and hence need to build their own power stations, which may not always be “green” energy.

Reliability and durability are critical for these vehicles. Downtime means time without an income stream for any revenue-generating vehicle. So, uptime is of the utmost importance.

Finally, let me end with an often-overlooked area - people. Transitioning to electric vehicles requires retraining a great deal of the workforce. Most have never worked with or on an electric vehicle, so there are many misconceptions and much education that needs to be done.

As industries like mining and construction look to electrify, what role does ABS play in supporting this transition, and how do you envision this trend impacting both industries and the broader battery market in the coming years?

ABS is your battery partner! With our line of off-the-shelf high-voltage Proliance Intelligent Battery Series™ and our low-voltage Alliance Intelligent Battery Series™, we offer solutions that are ready to ship today and that require no engineering development. At the same time, we recognize that our customers are not a “one-size-fits-all” and, therefore, we also do custom battery development for those customers whose requirements cannot be met with our off-the-shelf products. This week at the Battery Show 2024, we will launch our new Proliance T350V-50 Series packs. This is a set of two 350 V packs, connected in series to build a 700 V 100 kWh building block. They can then be scaled in parallel groups up to more than 500 kWh. Customers are telling us they like these because of the ease and flexibility of packaging.

But more than just being a battery supplier, we aim to be a partner helping to solve our customers’ challenges and enable them to do more. This is the trend that I see increasingly with small battery companies entering partnerships with much larger entities. We are amid the battery pack consolidation, where those companies most likely to survive are those that can successfully partner with a larger company. For ABS the Komatsu relationship puts us in a position to succeed.

The Battery Show is a key platform for industry professionals to share ideas and innovations. What are you most excited to see or discuss at this year’s event, and how does this conference contribute to shaping the future of the battery industry?

As always, I am most excited to see so many people face-to-face! The Battery Show has become such an amazing forum to meet new people and learn about new technologies that I look forward to it every year. I am always on the lookout for technologies that we can add to our existing products in the near term and that may help us shape our technology roadmap in the long term. Two technologies that I am following closely are silicon anodes and solid-state batteries. Both can potentially move us into the next stage of battery development.

About the Speaker

Dr. John Warner is a well-recognized figure in the battery industry. He is an authority on EV batteries, an experienced sales, business development, strategic marketing, and product management executive with more than 30 years of combined automotive and battery industry experience and author of three successful books on EV batteries.

Today he serves as one of the co-founders and Chief Customer Officer for American Battery Solutions, a lithium-ion battery pack manufacturer based in Michigan and Ohio where he is focused in on- and off-road mobility battery development.

This information has been sourced, reviewed and adapted from materials provided by The Battery Show.

For more information on this source, please visit The Battery Show.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.