Industry 4.0, robotic applications, and automation have altered manufacturing in various industries and ways. Though traditional handcraft is restored in many places, automation expands across industries and countries due to the numerous benefits robotic applications offer.

Data, energy, metal, plastic, and sometimes Terminator™ are typically among the initial associations when considering automated assembly and robots. Tapes are not usually among that list, but this could change upon deeper consideration of how feeding robots with specific tapes and materials can enhance quality and productivity.

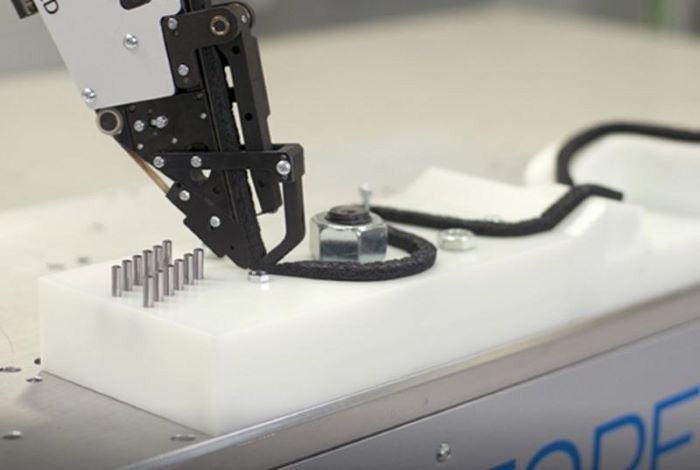

Figure 1. A depiction of a robot applying automated foam. Image Credit: Saint-Gobain Tape Solutions

Cobots, Robots & Co and Manufacturing

The Unimate was the first industrial robot, released in 1961 by George Devol and Joseph Engelberger, created for factories to undertake the repetitive task of lifting and moving hot metal across areas.

This automation breakthrough revolutionized the manufacturing industry by enabling machines to complete tasks previously performed by humans. This resulted in continuous production opportunities, increased productivity, reduced labor costs, and improved precision, accuracy, and product quality while reducing errors.

More significantly, robots and cobots ease the burden on human workers and can improve safety by completing tasks that are too dangerous or difficult for humans, including working with hazardous materials or loads and tasks in extreme conditions.

In industrial automation, there are two main types of machines, differentiated through intended use and degree of human interaction:

- Robots typically operate without direct human supervision and perform highly repetitive or dangerous tasks quickly and precisely, particularly in mass production. Often utilized in assembly lines, like in the automotive industry, they are designed explicitly for fewer tasks with limited options for adaptation.

- Cobots (collaborative robots) are usually smaller, more flexible, and easier to program than traditional robots, ideal for working with humans on small-batch manufacturing. Cobots are the best choice where frequent task changes, short programming time, and flexibility are needed.

Special Materials to Enhance Assembly, Productivity, and Process Costs

Adhesive tapes have a definitive role in automated production processes and provide real-world, measurable competitive benefits.

Robots must be fed with tapes or other materials required for assembly. Not all adhesive tapes are appropriate for robotic applications or automated assembly processes. Saint-Gobain® Tape Solutions offers several products that add significant value to such methods.

Norseal® Extruded Foam Profiles offer a long, continuous length suited to automation. These profiles have been utilized in making sandwich panel gaskets and sealing the interfaces of walk-in refrigerators and appliances.

The continuous format allows for exceptionally long running times for robots and other machinery. It also enables higher machine speeds, reduced stoppage time, and improved quality with fewer spliced sections. Many profiles are provided as a round gasket, but other shapes can be made.

Image Credit: Saint-Gobain Tape Solutions

Acrylic tapes like the Norbond Z3000, Norbond Z2000, and others can be converted to spools with secondary release liners in automotive exterior bonding applications, including automotive exterior trim component bonding like body side pillars or moldings. Tapes can greatly facilitate electric and automotive vehicle manufacturing when unwound from spools and then applied in either flexible or fixed automation.

Double-sided acrylic foam tapes in a spool format can be applied through a robotic tape application head. These robots can repeatedly apply pressure-sensitive tapes to curved surfaces more efficiently than by hand. It is also possible to pre-qualify a tape with a robot to test its ability to use the tape correctly and ensure it is feeding efficiently.

While not a tape, Dynafoam® Foam-in-Place polyurethane foam seals out water, dust, and air and decouples noise vibrations. Due to its engineered viscosity and mechanical foaming, Dynafoam demonstrates exceptional thixotropic behavior and allows for three-dimensional and upside-down applications.

In the automotive and construction industries, the continuous and seamless application to complicated shapes makes it perfect for doors and other automotive gasketing applications or sealing sandwich panels in prefab construction, guaranteeing repeatable quality and performance while saving time and labor costs.

Ultra-high molecular weight polyethylene (UHMW) tapes can be useful in inventory management, process flow, and other applications. Polytetrafluoroethylene, UHMW, and silicone rubber products are perfect for applications that require long life, durability, and contamination-free wear surfaces.

Figure2. Automated foam application via robot. Image Credit: Saint-Gobain Tape Solutions

How Tape Can Help Robots Save the Planet

Industrial robots can help save the planet by offering companies more efficient and profitable production while improving sustainability efforts and reducing waste, planting trees, or interacting with artificial intelligence to enable easier, more efficient recycling.

The switch to automation in production is becoming prevalent, and Saint-Gobain allows companies to benefit from this development with tapes and materials ideal for feeding robots and bringing businesses to life.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.