In advanced manufacturing, ensuring the durability of critical components is central to the safety of several products across a wide range of industries, such as aerospace and automotive. Yet the degradation of materials under extreme conditions remains an ever-present challenge, necessitating precise analysis and timely interventions.

In the early 2000s, an F-16 fighter jet crashed off the Luke Air Force Base in Arizona when one of its nickel superalloy turbine blades failed due to fatigue-induced cracking. While the pilot ejected safely, this incident exemplifies the importance of thorough testing and inspection of superalloy components, especially in high-stress operating conditions.

Single-crystal nickel superalloy blades were developed with enhanced resistance to creep and fatigue by eliminating grain boundaries, but without proper analysis, they, too, risk failure, which can lead to the loss of expensive materials and even life.1

Image Credit: Ali _Cobanoglu/Shutterstock.com

Problem: Limitations of Traditional Material Analysis in Extreme Conditions

Nickel-based superalloys, so-named for their ability to operate in extreme environments, play a major role in the aerospace, automotive, and energy sectors.2 Recognized for their exceptional mechanical properties, these superalloys are designed to withstand high temperatures, corrosion, and mechanical stress. Among the second-generation single-crystal superalloys, René N5 demonstrates notable resistance to creep and oxidation, so it has become a popular choice for hot-end components like turbine blades in aero-engine and gas turbines.3

However, understanding the long-term performance of nickel-based superalloys requires detailed characterization of their microstructural and compositional changes. This is especially important for predicting material failure and optimizing designs to meet the rigorous demands of high-temperature applications.3

A major obstacle in this area is the accurate and efficient analysis of complex alloy phases, surface oxidation, carbides, and pores, particularly when dealing with large or non-standard samples.4 Traditional microscopy and elemental analysis techniques can fail to provide comprehensive, real-time insights without extensive sample preparation or long analysis times.

Challenges: The Complexities of Material Characterization

The study of René N5 under extreme conditions presents several complexities:

1. Microstructural Analysis: The alloy contains multiple metallic phases, including γ and γ' phases, which govern its mechanical properties. Distinguishing between these phases and understanding their distribution is critical for assessing material integrity after exposure to high temperatures.4

2. Surface Corrosion: Oxidation at high temperatures leads to the formation of oxides and nitrides on the alloy's surface, which can degrade performance. Characterizing these surface reactions and their impact on the underlying metal is essential for predicting long-term durability.4

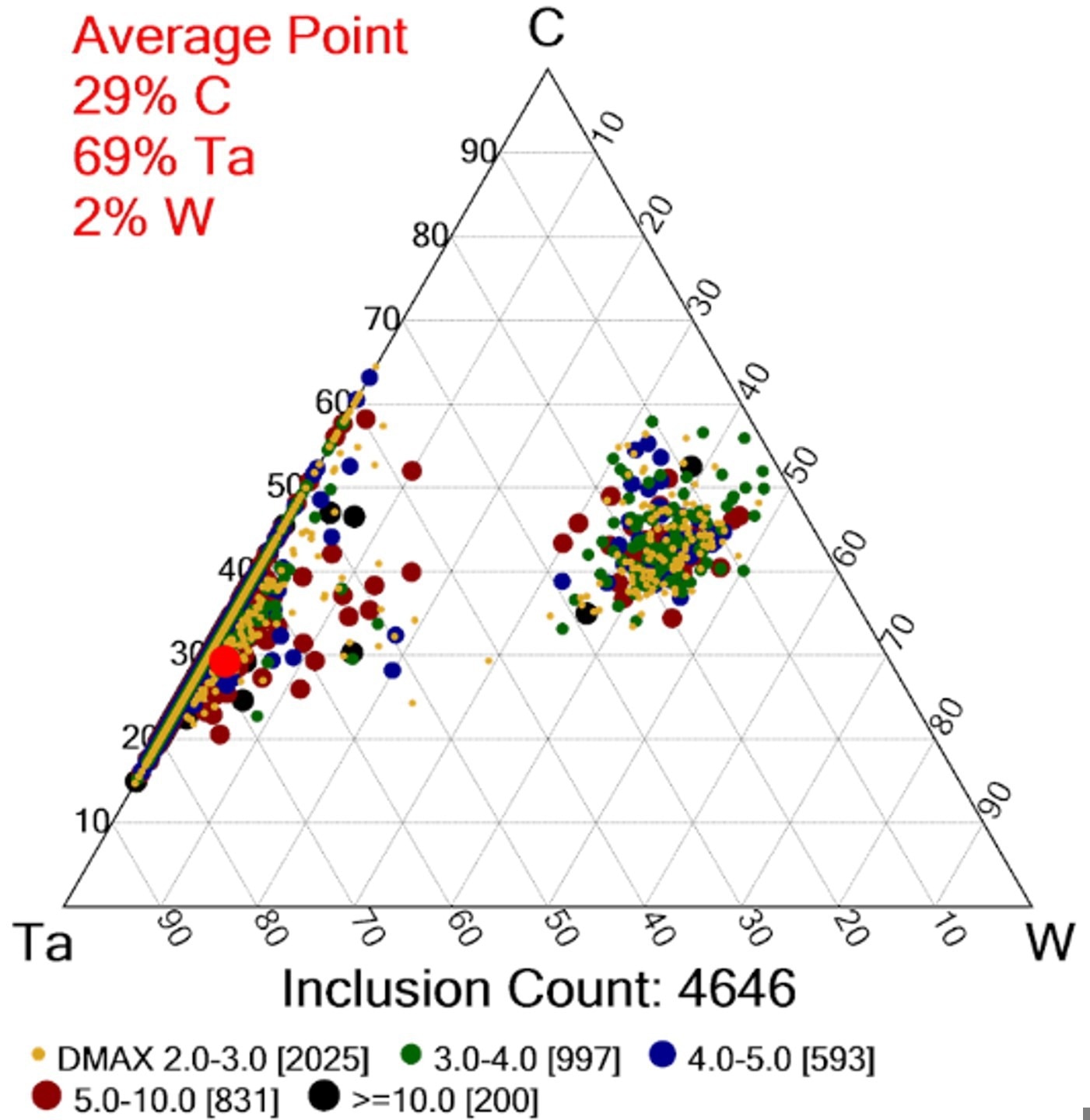

3. Pore and Precipitate Analysis: Manufacturing processes and operational stresses can introduce pores and carbides into the alloy. Understanding their size, shape, and distribution and their impact on material properties is important when optimizing product designs.4

Traditional methods for addressing these challenges often involve multiple, time-consuming techniques that require significant user input, including separate imaging, elemental analysis, and manual data processing. This increases the time and cost of analysis and introduces the potential for human error.

Solution: Introducing the Apreo ChemiSEM by Thermo Scientific

The Apreo ChemiSEM offers a comprehensive solution to the challenges of superalloy analysis, particularly for nickel-based materials like René N5. By integrating imaging, energy-dispersive X-ray spectroscopy (EDS), and automated phase analysis in a single platform, researchers can obtain real-time, high-resolution insights into the composition and structure of materials with minimal sample preparation.4,5

The Apreo ChemiSEM confers the following advantages for superalloy research:

1. Simultaneous Imaging and Chemical Analysis

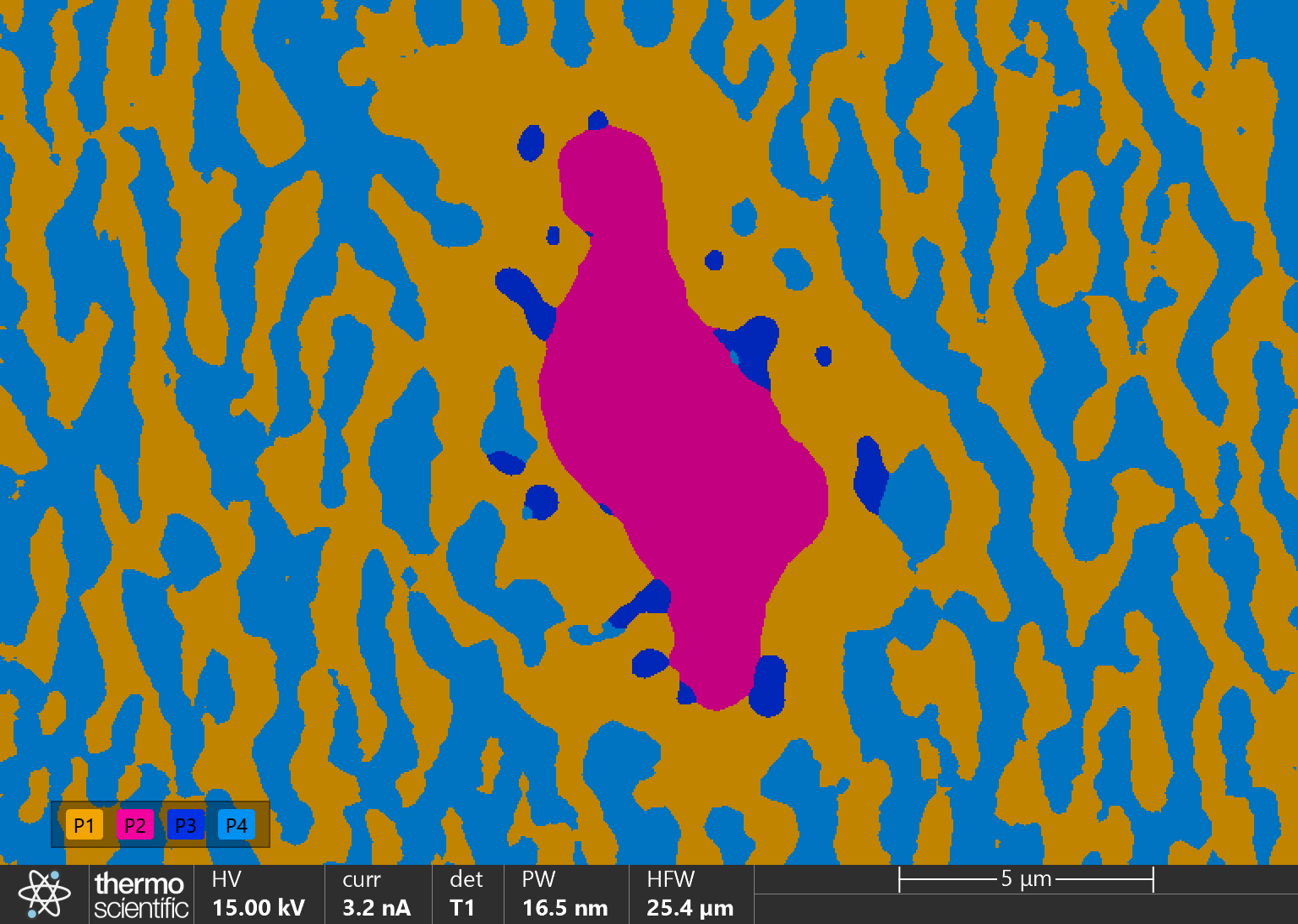

The Apreo ChemiSEM allows users to simultaneously capture electron and X-ray signals, facilitating immediate visualization of sample structure alongside compositional data. This feature is especially valuable when characterizing the γ and γ' phases in René N5, where traditional characterization methods might require multiple passes to gather the necessary data.4,5

2. Automated Phase Analysis with ChemiPhase

Apreo ChemiSEM's ChemiPhase feature eliminates the need for manual phase characterization. It supports the identification of different materials when a complex composition makes EDS insufficient to provide the necessary information.

Image Credit: Thermo Fisher Scientific

The system provides accurate, automated results with minimal user intervention by analyzing the composition and distribution of phases such as γ, γ', and various carbides in a single acquisition. This reduces the time and potential errors associated with manual analysis.4,5

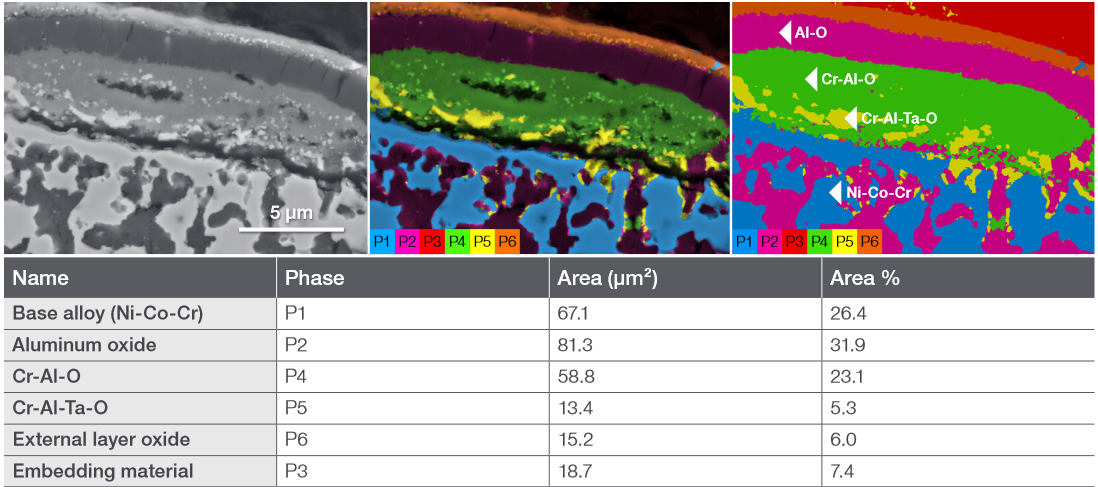

3. Advanced Surface Oxidation Characterization

The Apreo ChemiSEM excels at analyzing surface reactions like oxidation and nitridation. Using the integrated EDS and ChemiPhase capabilities, researchers can quantify the extent of surface degradation, such as forming aluminum oxides and nitrides in thermally cycled René N5 samples, and assess their impact on material performance.4,5

Image Credit: Thermo Fisher Scientific

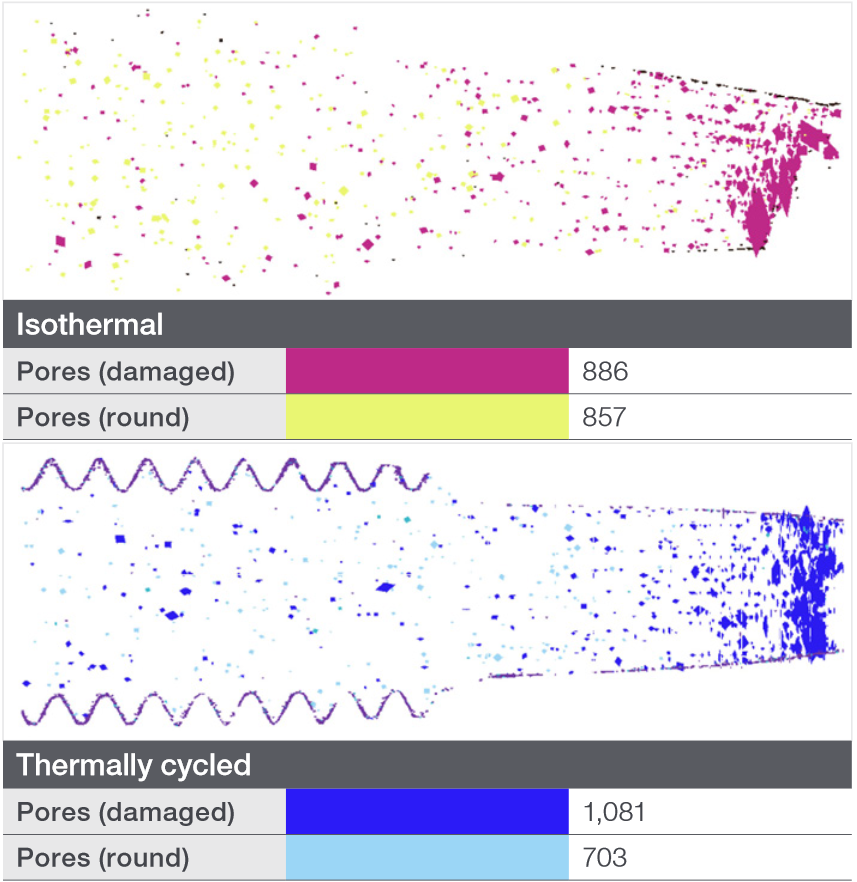

4. Pore and Precipitate Mapping with Perception Software

By automating the identification and measurement of pores, carbides, and other precipitates, the Apreo ChemiSEM speeds up the analysis process while providing detailed insights into material defects. This is critical for industries like aerospace and automotive, where even minor defects can induce catastrophic failures.4,5

Image Credit: Thermo Fisher Scientific

Image Credit: Thermo Fisher Scientific

Case Study: A Real-World Application of the Apreo ChemiSEM

In a recent study, the Apreo ChemiSEM was employed to analyze René N5 samples subjected to high-temperature creep tests.

The results highlighted the system’s ability to characterize both isothermal and thermally cycled samples, identifying key differences in strain, surface oxidation, and the formation of nitrides and carbides.

One finding revealed that the thermally cycled sample exhibited a dense population of aluminum nitrides, less prevalent in the isothermal sample.

This level of detailed analysis, facilitated by ChemiPhase and Perception software, enabled researchers to formulate meaningful predictions about the material’s behavior under real-world conditions.4

Conclusion: A Tool for the Future of Materials Science

Following the F-16 fighter jet crash in Arizona, a research team developed techniques to assess grain boundaries in the alloy. These techniques enable maintenance crews and manufacturers to identify turbine blades that need to be removed from service or require closer inspection during quality control processes.

In this context, Thermo Scientific’s Apreo ChemiSEM offers an ideal solution, significantly enhancing such inspection processes.

With its advanced imaging and analytical capabilities, the Apreo ChemiSEM provides a more efficient, real-time approach to examining high-performance alloys like René N5.

In addressing key challenges in the aerospace, automotive, and battery industries, it offers the comprehensive insights necessary to drive innovation and improve material performance, making it an indispensable tool for preventing future failures.

The Apreo ChemiSEM offers an unmatched combination of speed, accuracy, and automation for researchers and engineers looking to stay at the forefront of metal research.

As materials evolve to meet modern industry demands, Thermo Scientific remains committed to providing the tools needed to push the boundaries of material analysis.

References and Further Reading

- Jacoby, M. (2022). How materials scientists investigate aviation mishaps. [online] Chemical & Engineering News. Available at: https://cen.acs.org/materials/materials-scientists-investigate-plane-crashes/100/i42.

- Aerospace materials: past, present and future. (2012). Introduction to Aerospace Materials, pp.15–38. https://doi.org/10.1533/9780857095152.15.

- Shang, Z., et al. (2020). Microstructure and mechanical properties of a new nickel-based single crystal superalloy. Journal of Materials Research and Technology, [online] 9(5), pp.11641–11649. https://doi.org/10.1016/j.jmrt.2020.08.032.

- Scarpellini, Alice., et al. (2024). Characterization of high-temperature corrosion and particle analysis with the Apreo ChemiSEM. Thermo Fisher Scientific. https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/novel-analysis-single-crystal-rene-n5-superalloy-an0244-en.pdf

- Thermo Scientific Apreo ChemiSEM System Datasheet, Thermo Scientific Apreo ChemiSEM System. https://assets.thermofisher.com/TFS-Assets/MSD/Datasheets/apreo-chemisem-system-ds0508-en.pdf.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions.