A “tool” is something used to make or shape objects, such as a hammer, lathe, saw, or mold. Tools can be utilized once or several times and can be simple or sophisticated.

Image Credit: Scott Bader Company Ltd.

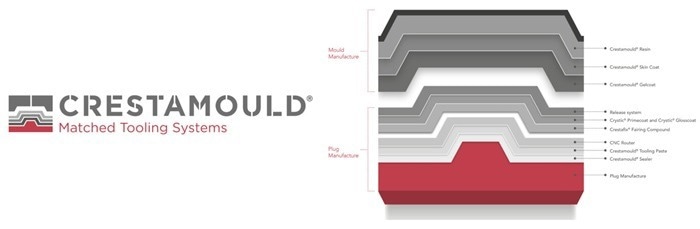

To make a composite part, it is necessary to:

- Create a mold (“tool”) to make the part in its developed shape

- Molds can be produced directly from metals and other suitable solids

- Molds are often built from a shape that is identical to the part being made

- The pattern may be an existing molding (a “plug”) or made from scratch via fairing compounds over a wooden or foam base

Image Credit: Scott Bader Company Ltd.

Scott Bader’s Crestamould-matched tooling range includes various products. Tool quality is fundamental to the quality of composite part production.

Plug Making

A plug is an existing molding used to make a new mold. Historically, plugs have been made from wood and from scratch. However, this process was slow and depended on the individual’s ability to properly understand engineering drawings.

Joints and bond lines may also impact the stability and surface finish, and wood is vulnerable to ambient temperature and humidity fluctuations.

A more design-friendly technique is required for contemporary, complex, or streamlined designs. Contemporary CNC approaches make it possible for plugs to be directly made from a solid material, usually MDF or a sturdy foam made from polyurethane or polystyrene.

These materials may be coated with a “fairing layer,” typically a polyester or epoxy-based thermosetting resin compound. A specialized coating is then applied to guarantee the needed level of finish. Lastly, a release agent allows the mold to be removed from the plug with minimal to no damage.

Scott Bader’s Plug-Making Materials

Wood, MDF, and foam are decent pattern materials, but they cannot be machined accurately for contemporary designs.

Scott Bader provides Crestamould T29 tooling pastes, applied thickly—up to 25 mm—for precision 3-axis CNC milling machines to attain their final shape. The paste can be used as a spray or extrusion and is sufficiently strong to withstand the stress of mold building. It can also be utilized to build limited-production molds directly.

This information has been sourced, reviewed and adapted from materials provided by Scott Bader Company Ltd.

For more information on this source, please visit Scott Bader Company Ltd.