| Graffiti, together with other forms of vandalism, is a serious problem for society both in financial and social terms. The Cost of Graffiti Removal The cost of graffiti removal has been estimated as exceeding £200 million per year in the UK alone, with the European financial burden topping £500 million, and a whopping £2 billion spent in the US annually It is also clear that street graffiti is a sign of sociological decay, causing anguish and stress in those directly affected, and fostering a wish to be elsewhere in both residents and visitors. Graffiti commonly found on schools and shops, in stairwells of blocks of flats, and on public transport vehicles and stations is quite simply an eyesore. Added Costs or Graffiti Removal Since graffiti removal is such a large scale activity, consideration must be also be given to the effects of the removal chemicals on the environment and on the cleaners themselves. Research in Sweden has identified a high prevalence of symptoms such as fatigue and headaches, as well as irritation of the eyes and respiratory tract, among workers involved in graffiti removal. Anti-Graffiti Barriers As it is not usually possible to prevent graffiti, removal methods must be both efficient and fast. The best method of easing graffiti removal is generally agreed to be the insertion of a barrier between the surface and the defacing material, such as paint spray, crayon or marker pen. Sacrificial Anti-Graffiti Coatings Anti-graffiti barriers and coatings fall into three distinct categories. Sacrificial coatings are mostly based on easily removable waxes. After soiling with graffiti, both the wax and graffiti are removed together, sometimes with solvents or more commonly by melting the wax with steam or hot water. The biggest problem with this approach is that the coatings must be replaced after each removal operation, which is time consuming and expensive. Semi-Permanent Anti-Graffiti Coatings Semi-permanent coatings are commonly based on acrylics or cross-linking systems, such as epoxy, urethane or polyester. They can be multi-coat systems that possess a moderate degree of resistance to aggressive cleaning chemicals. These coatings will normally withstand a few graffiti-removal operations with strong chemicals, but eventually attack by the removal chemicals makes replacement necessary. Aggressive removers are necessary as the marking media usually has some affinity for the coating and a degree of adhesion or diffusion of the marking media takes place, which tends to increase with time. Permanent Anti-Graffiti Coatings Permanent coatings are relatively new and offer an extremely long-life surface from which graffiti, fly-posters and other soiling can be removed repeatedly, using safe and mild agents, without the loss of properties, performance or appearance of the coating itself. Coatings of this type normally have release properties similar to those of non-stick domestic kitchenware. Any soiling can easily be removed using aqueous surfactant/detergent mixtures, or at worst, benign chemical mixtures which have little or no effect on the coating itself, resulting in a truly permanent anti-graffiti coating. Non-Stick Surfaces Fluorine-Based Non-Stick Systems The two elements fluorine and silicon are pre-eminent in the world of non-stick applications. Most people are familiar with non-stick frying pans and baking utensils, which have a polymeric coating resin containing fluorine atoms. One of the most familiar examples of these coatings is Teflon, a PTFE polymer which owes its non-stick characteristics to the high fluorine content of the structure. Unfortunately, fluorine-containing polymeric resins are expensive and extremely difficult to apply, but the degree of non-stick achieved can be extremely high. Silicon-Based Non-Stick Systems Silicon atoms, joined to oxygen atoms in long molecular chains, produce silicone molecules with variants called silanes and siloxanes. Resins made from long chains with alternating silicon and oxygen atoms, when dried or suitably cross-linked, can result in non-stick coating systems. The degree of non-stick is nearly as high as that achieved with fluorine-containing coatings, but the price is normally much lower and the case of application on most surfaces is usually improved. Other Chemically-Active Groups Used in Non-Stick Systems Some semi-permanent anti-graffiti coatings, even when fully-cured, still have chemically-active groups such as hydroxyls and keto-groups at their surfaces. Sometimes, these groups can act as bonding-sites for graffiti resins, making them quite difficult to remove. So cleaning requires the use of chemicals capable of breaking these bonds. Additionally, mild abrasion is sometimes required in order to supplement the chemical action. This has a deleterious effect upon the coating itself, even after relatively few cleaning cycles. Disadvantages of Non-Stick Systems To get around these problems of degradation, largely chemically-inert coatings such as fluorinated resin systems and silicones/siloxanes are popular. These are inherently non-stick, having few or no bonding-sites to which graffiti inks can adhere. Unfortunately, most fluorinated-resin systems also have other problems, such as the need to use unwholesome curing agents or activators (such as isocyanates), and the use of smelly, toxic and flammable solvents for the resin or curing agent. Epoxy-Modified Siloxane Anti-Graffiti System One epoxy-modified, siloxane clear coating system recently developed for Urban Hygiene, an anti-graffiti coatings manufacturer, has been undergoing a series of laboratory and in-use tests. The coating has proved that it can overcome some of the existing problems with these types of coatings, many of which are not able to provide a clear finish. The Systems and Its Properties The engineered siloxane has a two pack, high-solids system that is virtually solvent-free, has few bonding sites for defacement inks, and has very high resistance to abrasion when fully-cured, so it is extremely resistant to the less aggressive chemicals used to remove graffiti. The single-coat system has a low cost per unit area, and most importantly, can be purged of graffiti with the mildest of environmentally-safe chemicals, retaining its non-stick surface-energy after dozens of cleaning cycles. Samples Suitable for Permanent Anti-Graffiti Coatings To verify that the engineered siloxane was suitable for characterisation as a true permanent anti-graffiti coating, it was coated onto a mild steel surface. Attempts were made to produce a final dry film thickness of around 30µ, and the average measured thickness from the five specimens was 36µ. Evaluating Anti-Graffiti Properties After full cure had been achieved (in around seven days), each panel was defaced using aerosol paint and permanent marker, the two most common forms of graffiti media, and the graffiti was left in place for 24 hours before any cleaning was carried out. A benign, water-soluble mixture of higher-esters, an adipate, a succinate and a glutarate were used for cleaning. Samples Suitable for Semi-Permanent Anti-Graffiti Coatings To test the semi-permanent coating, epoxy resin-type, two-pack, brush‑coated coating was also applied and allowed to reach full cure in the same time. The coating and testing regime was the same as for the permanent coating. Cleaning Fluids Used for Evaluating Semi-Permanent Anti-Graffiti Coatings The benign, mixed ester cleaner used on the semi-permanent coating did not fully remove the graffiti produced by the marker-pen or the paint-aerosol, even after a small number of cleaning operations, so cleaning liquids recommended by the coating supplier were used. These were based on more aggressive chemicals than those in the mixed ester cleaner. Measurements and Observations After each cleaning operation, the coating film thickness was measured, and a visual assessment of changes in gloss was made, together with notes on any other changes in properties (loss of coating, tackiness, colour changes, etc). Twenty-four thickness measurements were made daily on each of the test panels and results were expressed as the mean of the readings. In both cases (marker pen and aerosol-spray) the fouling and cleaning regimes were repeated 52 times to simulate weekly cleaning of graffiti from the coating. Results of Testing on Anti-Graffiti Coatings Thickness Variations A small variation in the thickness of the permanent coating was observed after numerous removals of the permanent marker and aerosol paint graffiti. The thickness of the semi-permanent coating deteriorated rapidly after only a few cleaning operations, however, and in many areas no coating remained on the test-panels after cleaning. |

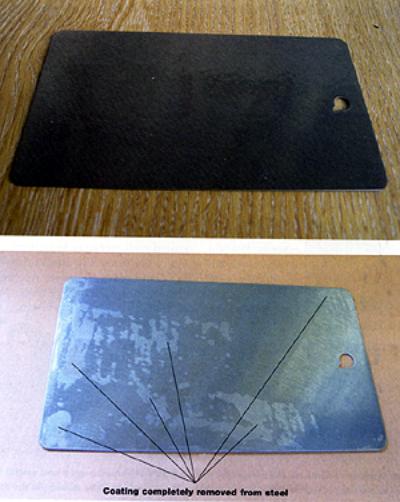

| | Figure 1. The permanent polysiloxane coating holds up well after many removal operations (top), while the semi-permanent coating has many areas where the coating has been completely removed. | Other Physical Properties There was no change in appearance, loss of coating or tackiness observed with the permanent coating, whereas the semi-permanent epoxy coating showed considerable loss of overall thickness in those areas where it remained, and there was complete removal from around 10% of the steel substrate. Each graffiti removal operation left the coated areas feeling tacky to the touch, indicating chemical attack, swelling or softening by the aggressive chemicals necessary for full removal. Most of the original gloss and clarity was also lost. Commercial Acceptance of the Permanent Anti-Graffiti Coating The engineered siloxane is already in use on many buildings and public transport systems throughout Europe, and is now widely regarded as the best coating of its type currently available. Urban Hygiene, who has exclusive European marketing rights to the siloxane coating, is currently working with major European and UK companies in the development of the coating system for use on new trains being introduced worldwide. Behaviour in Fire Situations The use of the coating in tunnel areas is also valuable as it is essential to minimise the risk from inhalation of toxic fumes that could be released in fires. The siloxane coating achieved excellent results in tests establishing that only a non-hazardous trace of nitrogen was evolved when the coating was exposed to intense heat. It was this result which proved that the material would be acceptable for use in sub-surface and station locations belonging to London Underground Ltd, UK. Comments from Users of the Ant-Graffiti Coating School facilities managers have also sung the coating’s praises. One caretaker from a school in Twickenham, UK, says ‘Coating school surfaces with the engineered polysiloxane has made life a lot easier. When we get graffiti now we use the benign remover and easily clean it off.’ A finances and premises manager from an Essex school remarks that ‘the coating gives the walls a fresh look and the maintenance staff are extremely happy that any marks disappear easily’. Summary For those who live in urban areas, the promise of eradicating graffiti from their daily view is certainly a highly appealing one and thanks to the new engineered siloxane coating, could soon become a reality |