Traditionally ceramics are classed as clay-based materials. However, as the field of ceramics has expanded, they can be defined as inorganic, non-metallic materials that are heat treated during processing or use. They tend to be brittle, hard and inert, and have ionic or covalent bonding. Diamond meets all of these criteria.

Image Credit: Bjoern Wylezich/Shutterstock.com

Diamond is a form of carbon that is crystallised in a cubic structure with each carbon atom linked by a strong, rigid chemical bond to four other atoms.

Until the 1950s, diamond was available in relatively small quantities at fairly high prices, the word creating an image of brilliant gemstones and wealth. The broad range of valuable properties has driven the development of routes to make synthetic diamonds, which has produced new products and applications.

Where are Diamonds Found?

Diamond can now be found from several sources:

- Naturally occurring diamond; about 20 tonnes of diamond are mined each year. Half are gem quality and half are industrial quality.

- Synthetic single crystal diamond; about 90 tonnes of diamond are made annually by the high-pressure and high-temperature (HPHT) method. Most industrial diamond is made from graphite at pressures of 4.5 to 6.0 GPa and temperatures of 1400 to 1600 °C with the aid of a molten transition metal catalyst. These diamonds are considerably cheaper than natural diamond.

- Polycrystalline diamonds are formed usually by either cementing diamond grains together using metal as a bonding agent or sintering using Boron Carbide as a sintering aid.

- Vapour phase deposition. Both chemical vapour deposition (CVD) and physical vapour phase deposition (PVD) produce thin diamond films. About 10 tonnes of vapour phase grown diamond films are produce annually. Their cost is more than four times that of naturally occurring diamond. However, their application can be justified economically as they are used in thin film form and make a significant difference to component properties.

Key Properties of Diamond

Diamond provides an impressive combination of chemical, physical and mechanical properties:

- The hardest known material

- Low coefficient of friction

- High thermal conductivity

- High electrical resistivity

- Low thermal expansion coefficient

- High strength

- Broad optical transparency from ultraviolet to infrared

- Resistant to chemical corrosion

- Biologically compatible

Typical physical and mechanical properties are listed in table 1.

Diamond has limitations. It is meta stable at room temperature and pressure, forming a black coat when heated to above 600 °C in oxygen and reverting to graphite when heated in nitrogen at around 1500 °C.

Diamond will react with strong carbide-forming metals (i.e. tungsten, tantalum and zirconium). It dissolves in iron, cobalt, manganese, nickel, chromium and the platinum-group metals.

Table 1. Typical physical and mechanical properties for diamond.

| Property |

Value |

| Density (g/cm3) |

3.50 |

| Young’s Modulus (GPa) |

1050 |

| Bend Strength (MPa) |

850 |

| Fracture Toughness K1c (MPa.m0.5) |

3.5 |

| Hardness (GPa) |

45 |

| Thermal Expansion Coefficient (x 10-6/°C) |

1.1 |

| Coefficient of Friction |

0.02 |

| Electrical Resistivity (ohm.cm) |

>1013 |

| Thermal Conductivity (W/mK) |

400 |

| Decomposition Temperature in nitrogen (°C) |

1500 |

What are the Uses of Diamond?

The applications of diamonds have grown enormously, exploiting the unique combination of properties and the increased availability of the material as synthesis methods developed. The following applications are covered in more detail below:

Cutting Tools and Wear Components

The properties exploited by these applications are hardness, strength, low thermal expansion coefficient, low friction coefficient and chemical resistivity.

Some of the products in this area include oil drilling bits, rock drill cutters, wire drawing dies, extrusion dies, cutting tool inserts, optical grinding tools, coatings for computer hard discs and coatings for ball bearings.

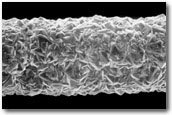

Either polycrystalline diamond or diamond coatings can be used in this area (see figure 1). When using coatings, manufacturers must pay attention to coating adhesion and ensure the coating is uniform and follows the component contours for successful use. The coating cannot be applied to ferrous materials as they will react and dissolve.

|

|

|

Figure 1. A diamond coated machine tool

|

Thermal Management in Substrates, Heat Spreaders and Heat Sinks

Diamond provides the unique combination of high thermal conductivity with electrical insulation.

Applications include hybrid circuit packages, heat sinks for laser diodes and small microwave power device, integrated circuit substrates and printed circuit boards. The use of diamond enables higher operating speed as devices can be more tightly packed without overheating. Further reliability improvements should be expected, as the junctions in the devices will be operating at lower temperature when mounted on diamond.

Semiconductor Devices

The electronic structure of diamond has a wide band gap giving it the potential for use as a semiconductor. However, there are a number of issues that must be overcome before diamond coatings are widely exploited in this area. Prime concerns are effectively doping the material and the growth of single crystal or highly oriented films. Active devices have been made from boron doped (p-type) films grown on diamond substrates. The devices are capable of operating at temperatures > 500 °C compared with a maximum operating temperature of 200 °C for silicon and gallium arsenide devices.

Potential applications include very high power transistors, high temperature integrated circuits, piezoelectric devices and radiation hardened integrated circuits.

Optical Components

Diamond is starting to be used in optical components, particularly as a protective coating for infrared optics in harsh environments. A thin layer of CVD diamond can protect Infra Red windows made from ZnS, ZnSe, and Ge, which are brittle and easily damaged. Future applications may use freestanding polycrystalline film, provided optical flatness can be achieved.

|

|

|

Figure 2. A diamond coated optical fibre.

|

High-Performance Applications of Diamond

The excellent properties of diamond have the potential to improve performance in many applications. The main barriers are cost and scale of production. For example, metal wires and fibres can be CVD coated with diamond increasing the modulus close to that of diamond and opening the possibility of stronger and stiffer composites, ceramic armour and projectiles. Further, micro components, such as micro gears 250 microns across and 12 microns thick, can be fabricated in diamond, for use in micro robots and micro mechanical devices and offering superior performance to currently available silicon and polysilicon components.