Virtually everything in our world is affected by paints or coatings in some way. Element Materials Technology (SMT) and its team of engineers and technicians possess the capability to test and analyze a variety of issues pertaining to paints and coatings. In addition, we provide a wide array of qualification testing to verify your process or design. Using the latest analytical equipment and techniques, we offer a qualified third-party perspective, delivering bottom-line results quickly and thoroughly.

Paints and Coatings

Virtually everything in the modern world has a paint, varnish, sealant or other coating - from armor piercing bullets to pacemakers.

Even simple house paint is an advanced chemical product.

Understanding the Properties of Coatings

Understanding the properties of these coatings is critical to predicting their long-term performance. Element Materials Technology offers a full range of testing and engineering services for organic and inorganic paint and coating materials, including:

- Specification compliance testing

- Field failures

- Production defects

- Materials analysis and deformulation

- Materials selection and specification development

- Consulting

- Line audits/troubleshooting

Data generated by Element Materials Technology scientists during paint and coating testing solves problems before they become costly. The following testing procedures add value to your manufacturing process.

Appearance Measurement

Color and gloss (20°, 60°, 85°).

Accelerated Weathering

Carbon Arc UV, Fluorescent UV and Xenon Arc UV.

Corrosion Evaluation

Neutral salt (salt fog), CASS, SWAAT, Cyclic (GM9540P) and electrochemical corrosion testing, water fog, controlled condensation, Cleveland condensing humidity exposures, and controlled temperature/humidity exposure.

Pretreatment Evaluations

Anodized coating weight, anodized seal quality, and conversion (phosphate) coating weight.

Failure Analysis and Material Identification

Element Materials Technology offer a range of testing services for the paints and coatings industry such as:

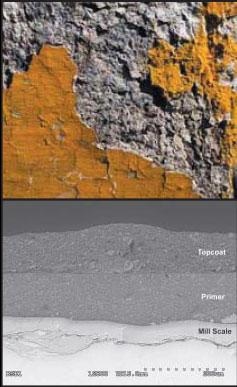

- Cross section inspection

- Metallography

- Scanning electron microscopy (SEM)

- Energy dispersive X-ray spectroscopy (EDS)

- Fourier transform infrared spectroscopy (FTIR)

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA)

- Evolved gas (TGA-FTIR), thermomechanical analysis (TMA)

- Gas chromatography/mass spectroscopy (GC/MS)

- Gas chromatography/infrared spectroscopy (GC/IR)

Physical Properties

Crosshatch and pull-off adhesion, pencil hardness, thickness measurement, Taber abrasion, density, volatile/nonvolatile content, viscosity, fl exibility, resistance to impact, chemical and heat, and post-exposure evaluations including rust, blisters, and creep.

Unique Partnering Opportunities

True synergy can result when Element Materials Technology becomes your testing partner and an extension of your operations. Working together, we can solve difficult problems, ensure material compliance to customer specifications, improve operating efficiency, and capitalize on unique materials opportunities.

Fatigue and Fracture In Environment - Short Version with Subtitles

Video Credit: Element Materials Technology

This information has been sourced, reviewed and adapted from materials provided by Element Materials Technology.

For more information on this source, please visit Element Materials Technology.