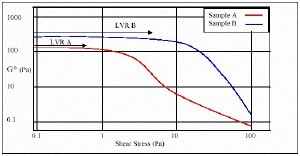

In this experiment, the sample is oscillated with an increasing stress known as an amplitude sweep and the storage and loss moduli are plotted against the shear stress. The moduli initially are independent of stress, giving a plateau known as the linear viscoelastic region (LVR). The length of the linear viscoelastic region shows how far the material can be deformed before the onset of structure breakdown.

Interpretation

Sample A gives a much shorter linear viscoelastic region (LVER) than Sample B and will therefore break down much more easily with vibrations and small movements. A long LVER indicates that the sample is more stable to oscillation stresses, and therefore strong associations have been formed between the particles.

For any single formulation, this gives an indication of how well dispersed the pigment is. From the results above, it can be seen that Sample A is not as well dispersed as Sample B.

Figure 1. Shear Stress vs. Complex Modulus for Two Samples.

Conclusion

A relatively quick amplitude sweep experiment can indicate the degree of dispersion of an ink and be used to optimise the dispersant dose and method. Unstable formulations can also be eliminated without the need for storage testing.

Measurement conditions

Sample: Ink pigments

Geometry: Cone and plate system 4˚/40 mm with a solvent trap system

Temperature: 20˚C

Stress amplitude sweep: 0.1 – 100 Pa Up Logarithmic

.png)

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.