A common problem encountered when extruding plastics is that they show melt fracture or ‘shark-skinning’. This is seen as a jagged surface on the extrudate. The problem is caused by the extrudate first ‘sticking’ to the die wall, then ‘slipping’ as the pressure builds.

When the shear rate is increased the flow becomes more plug-like and the surfaces will become smooth again. Sometimes a simple adjustment of shear rate range used in the extrusion process can create or dispose of shark-skinning problems.

Discussion

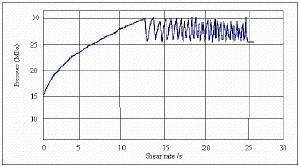

By plotting pressure vs. shear rate the onset and cessation of melt fracture can be seen. The melt fracture can be eliminated by the use of one or two routes. Either the extrusion shear rate can be altered so that it is outside the melt fracture region, or the formulation can be modified to change the melt fracture region.

It is worth noting that melt fracture is dependant on shear stress rather than shear rate, so the correlation between rheometer and process may not be exact.

Figure 1. Plot of Pressure vs. Shear Rate.

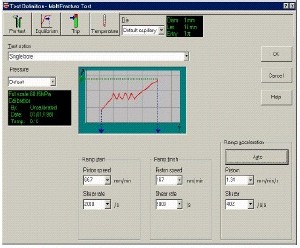

Figure 2. Measurement conditions for melt fracture test.

Conclusion

The Rosand Capillary Rheometer can be used to help formulate polymer compounds that will not give melt fracture problems during extrusion, this can help to eliminate many pilot scale trials. The rheometer only requires small sample volumes (c.50mls) making it ideal for research and development testing.

Measurement conditions

Sample: Polyethylene

Set-up Dies: 16 mm x 1 mm x 180˚

Set up Transducers: 10 KPSI

Pre-test Stage 1: 2Pa/50mm.min-1 hold for 4 minutes

Pre-test Stage 2: 2Pa/50mm.min-1 hold for 5 minutes

Shear Ramp Range: 2000-5,000 s-1, autorange ramp rate,

Shear Ramp Temperature: 190˚C or extrusion temperature

Equilibrium: By speed (v6 mode), Variation on standard rate=1, no filter, trip: 90%.

.png)

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.