|

Aluminium alloy 5005 contains nominally 0.8% magnesium. It has medium strength, good weldability, and good corrosion resistance in marine atmospheres. It also has the low density and excellent thermal conductivity common to all aluminium alloys. It is the most commonly used grade of aluminium in sheet and plate form.

Aluminium alloy 5005 is a lean aluminium magnesium alloy which can be hardened by cold work: it is not heat treatable to higher strength.

Austral Wright Metals can supply this alloy as plate, sheet and strip. See Austral Wright Metals Catalogue for normal stock sizes and tempers.

Corrosion Resistance of Aluminium Alloy 5005

Corrosion Resistance 5005 has the same high resistance to general corrosion as other non heat treatable aluminium alloys. It also has the higher resistance to slightly alkaline conditions common to the 5000 series alloys. The atmospheric corrosion resistance of 5005 is similar to that of 3003.

When anodised to improve corrosion resistance, the film on 5005 is clearer than on 3003, and gives better colour match with 6063 architectural extrusions.

The corrosion resistance of aluminium alloys relies on a protective surface oxide film, which when damaged is readily repaired by the rapid reaction between aluminium and oxygen. However, the high reactivity of the base metal can give rapid corrosion if the film cannot be repaired, so aluminium alloys are not suitable for use with reducing media.

Since aluminium is a reactive metal, it may corrode more quickly when in electrical contact with most other metals. The prediction of galvanic corrosion is complex, please consult Austral Wright Metals for specific advice.

Applications of Aluminium Alloy 5005

Typical Applications of aluminium alloy 5005 include:

- Architectural applications

- General sheet metal work

- High strength foil

Chemical Composition of Aluminium Alloy 5005

Table 1. Chemical composition of Aluminium 5005.

|

|

|

Aluminium

|

Balance

|

Manganese

|

0.20 max

|

|

Magnesium

|

0.50 – 1.10

|

Chromium

|

0.10 max

|

|

Silicon

|

0.30max

|

Zinc

|

0.25 max

|

|

Iron

|

0.07 max

|

Others, each

|

0.05 max

|

|

Copper

|

0.20 max

|

Others, total

|

0.15 max

|

Mechanical Properties of Aluminium Alloy 5005

Table 2. Typical mechanical properties of 5005 aluminium in various heat treated states.

|

|

|

O (annealed)

|

35

|

105 – 145

|

12 – 22

|

|

H12

|

95

|

125 – 165

|

2 – 8

|

|

H14

|

115

|

145 – 185

|

1 – 6

|

|

H16

|

135

|

165 – 205

|

1 – 3

|

|

H18

|

–

|

> 185

|

1 – 3

|

|

H32

|

85

|

115 – 160

|

3 – 9

|

|

H34

|

105

|

135 – 180

|

2 – 7

|

|

H36

|

125

|

160 – 200

|

1 – 4

|

|

H38

|

–

|

> 180

|

1 – 4

|

† For information only, proof stress is not specified or measured except by prior agreement

‡ Minimum elongation, actual value depends on thickness – thicker gauges have higher elongation

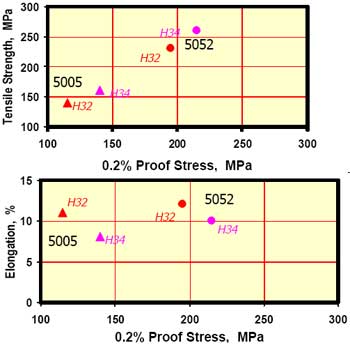

Typical strength and ductility of alloys 5005 & 5052 in the H32 & H34 tempers

Figure 1. Typical strength and ductility of aluminium 5005 and 5052 in H32 and H34 tempers.

Physical Properties of Aluminium Alloy 5005

Table 3. Typical physical properties of aluminium 5005.

|

|

|

Density

|

20°C

|

2,700

|

kg/m3

|

Specific Heat

|

20°C

|

900

|

J/kg.°C

|

|

Melting Range

|

|

632 – 655

|

°C

|

Mean Coefficient of Expansion

|

20°C

|

23.75 x 10-6

|

/°C

|

|

Modulus of Elasticity

|

|

|

|

Thermal Conductivity

|

25°C

|

201

|

W/m.°C

|

|

Tension

|

20°C

|

68.2

|

GPa

|

Electrical Resistivity

|

20°C

|

0.033

|

micro-ohm.m

|

|

Torsion

|

20°C

|

25.9

|

GPa

|

Electrical conductivity

|

|

|

|

|

Compression

|

20°C

|

69.5

|

GPa

|

equal volume

|

20°C

|

52

|

% IACS

|

|

|

|

|

|

equal weight

|

20°C

|

172

|

% IACS

|

Temper Conditions

Table 4. Summary of temper conditions for aluminium 5005.

|

|

|

O

|

Annealed (soft)

|

|

H1x

|

Strain hardened only

|

|

H3x

|

Strain hardened and then stabilised (i.e. low temperature heat treated to pre-empt natural ageing, by reducing strength and increasing ductility)

|

|

|

|

8

|

full hard

|

4

|

½ hard

|

|

6

|

¾ hard

|

2

|

¼ hard

|

Fabrication of Aluminium Alloy 5005

Fabrication aluminium 5005 is not generally hot worked. It is readily cold formable in the annealed condition, as it is a relatively soft and ductile alloy. Forming loads and tool & press wear are generally less than with carbon steel. For piercing and blanking the punch to die clearance should be about 6% of the thickness per side for the H32 & H34 tempers. Sharp tools are required.

Table 5. Indicative minimum bend radii for 90° cold forming for various thickness, t mm

|

|

|

H32

|

0 t

|

½ t

|

1 t

|

1½ t

|

2 t

|

|

H34

|

0 t

|

1 t

|

1½ t

|

2 t

|

2½ t

|

Machinability of Aluminium Alloy 5005

Aluminium 5005 is readily machinable by conventional methods. It should be machined at high speed with copious lubrication to avoid thermal distortion of the workpiece. Sharp tools are essential. High speed steel or tungsten carbide may be used. Cuts should be deep and continuous, with high cutting speeds.

Woodworking machinery may be suitable for short runs.

Welding Aluminium Alloy 5005

Welding 5005 is readily weldable by standard techniques. It is frequently welded with GTAW (TIG) or GMAW (MIG). Aluminium must be very dry & clean to avoid contamination & porosity of the weld. Filler metals 1100, 4043 or 4047 are used. 4043 is the most crack tolerant. Best colour match is obtained with 1188 filler metal. Shielding gas must be dry & free of hydrogen.

Heat Treatment of Aluminium Alloy 5005

Aluminium 5005 is annealed at 345°C, time at temperature and cooling rate are unimportant. Stress relief is rarely required, but can be carried out at about 220°C. If loss of strength is of concern, stress relief tests should be conducted.

ASTM Specifications

Table 6. ASM specifications for aluminium 5005.

|

|

|

B209

|

Aluminium and Aluminium Alloy Sheet and Plate

|

|

B316

|

Aluminium and Aluminium Alloy Rivet & Cold Heading Wire & Rods

|

|

B210

|

Aluminium and Aluminium Alloy Drawn Seamless Tubes

|

|

B483

|

Aluminium and Aluminium Alloy Drawn Tubes for General Purpose Applications

|

|