May 12 2001

Image Credit: StudioMolekuul/Shutterstock.com

Article updated on 27/02/20 by Clare Kiernan

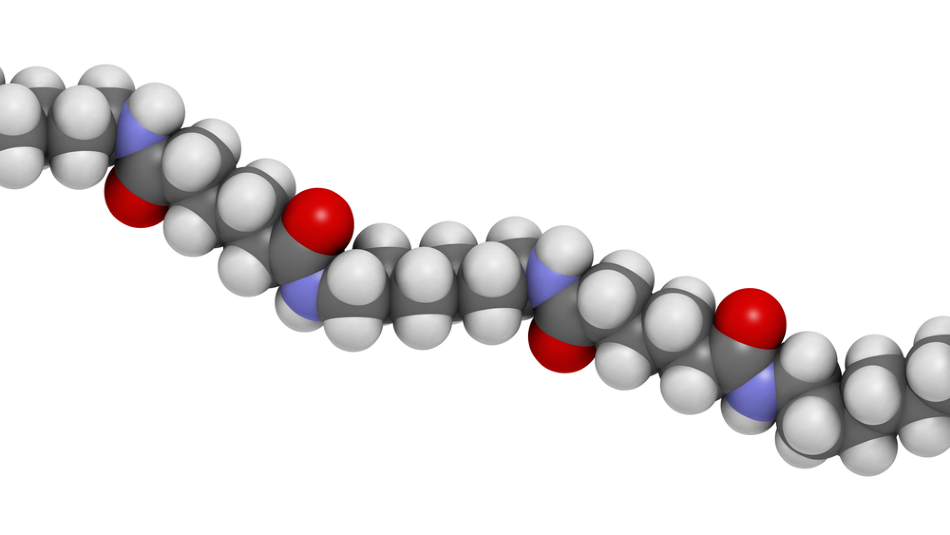

Initially developed to imitate the properties of Nylon 6/6, polyamide 6 (PA 6) is a semi-crystalline thermoplastic polymer. Its production was due to the patenting of Nylon 6/6 and the requirement for a material that had similar characteristics. Unlike other polyamides usually formed by condensation polymerization, PA 6 is formed by ring-opening polymerization. PA 6 can be reinforced by the inclusion of minerals in its structure giving it a distinct set of properties.

Advantages When Compared to Unmodified PA 6

- Increased tensile strength

- Higher flexural modulus

- Strong dimensional stability

- Higher stiffness

Disadvantages When Compared to Unmodified PA 6

- Significantly reduced notched izod impact strength

- Lower elongation at break

Typical Properties

|

|

|

|

Density (g/cm3)

|

1.55

|

|

Surface Hardness

|

SD75

|

|

Tensile Strength (MPa)

|

70

|

|

Flexural Modulus (GPa)

|

3

|

|

Notched Izod (kJ/m)

|

0.08

|

|

Linear Expansion (/°C x 10-5)

|

6

|

|

Elongation at Break (%)

|

10

|

|

Strain at Yield (%)

|

N/A

|

|

Max. Operating Temp. (°C)

|

80

|

|

Water Absorption (%)

|

0.5

|

|

Oxygen Index (%)

|

22

|

|

Flammability UL94

|

HB

|

|

Volume Resistivity (log ohm.cm)

|

15

|

|

Dielectric Strength (MV/m)

|

30

|

|

Dissipation Factor 1kHz

|

0.2

|

|

Dielectric Constant 1kHz

|

8

|

|

HDT @ 0.45 MPa (°C)

|

230

|

|

HDT @ 1.80 MPa (°C)

|

120

|

|

Material. Drying hrs @ (°C)

|

3 @ 95

|

|

Melting Temp. Range (°C)

|

260 - 290

|

|

Mould Shrinkage (%)

|

0.7

|

|

Mould Temp. Range (°C)

|

50 - 80

|

|

Applications

This may be utilized in creating casings and engineering parts requiring high stiffness and dimensional stability.

Source: Abstracted from Plascams

For more information on Plascams please visit RAPRA Technology Ltd.

|