Two component, room temperature curing epoxy potting/encapsulation system EP21FRNS-2 is flame retardant per the UL94V.0 standard. It has a convenient 1 to1 mix ratio, produces very low smoke levels and features a non-halogen filler. EP21FRNS-2 has high physical strength properties and is serviceable from -50°C to 90°C per the UL 94V.0 specification. It offers superior electrical insulation properties and has a dielectric constant of 4.5 at 60 Hz. Resistance to chemicals, moisture and thermal cycling is outstanding.

Master Bond EP21FRNS-2

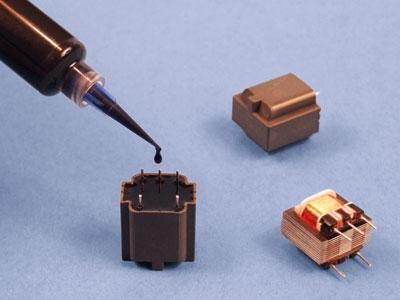

Master Bond EP21FRNS-2 has high bond strength to metals, ceramic, glass and most plastics. To optimize its properties the best cure schedule is overnight at room temperature, followed by 2-3 hours at 150-200°F. Working life for a 100 gram mass is 90-150 minutes at 75°F. EP21FRNS-2 has a flowable viscosity – ideal for potting and encapsulation.

Specialty Flame Resistant Compounds

Self-extinguishing flame retardant potting/encapsulation compounds offer electronic assemblies protection from hostile environmental conditions. From power supplies to sensors to aerospace switches to LED’s to transformers these products serve the needs of high-tech manufacturing companies. ROHS compliant these systems have low shrinkage and exceptional durability.

Cutting Edge Formulations

Master Bond's product line consists of advanced epoxies, silicones, polyurethanes, polysulfides, UV/LED cures and other specialty systems. Each compound is designed to meet specific application requirements. Master Bond's environmentally friendly systems are available in convenient packaging from small to large sizes.

Outstanding Technical Support

With years of experience in technical support, the Master Bond team will be able to assess your application and recommend the most suitable polymer system to meet your specifications. Master Bond will continue to guide you throughout the design, prototype and manufacturing process. Master Bond offers replacements for discontinued products.

Latest Technological Advancements

As a worldwide manufacturer of polymer compounds, Master Bond is continuously working with universities and R&D labs to improve product performance. Our products are designed to maximize productivity, reduce waste, save energy and for dependable, long term durability.

This information has been sourced, reviewed and adapted from materials provided by Master Bond Inc.

For more information on this source, please visit Master Bond Inc.