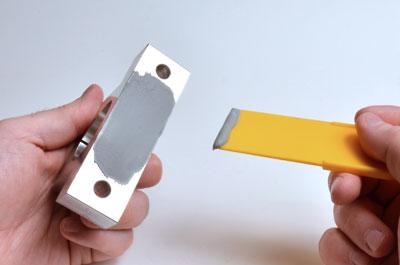

Master Bond SteelMaster43HT is a high-performance two component epoxy system for repair, rebuilding, restoring and resealing of worn or damaged metal components. It features compressive strength > 16,000 psi, excellent corrosion resistance, superior dimensional stability and serviceability from -60°F to +400°F. It is readily machinable after cure. Bonds withstand exposure to thermal cycling.

Master Bond SteelMaster43HT

This system is formulated to cure rapidly at room temperature. It has a 5 to 1 mix ratio by weight. SteelMaster43HT has a mixed viscosity of 120,000 cps. Working life for a 200 gram mass is 15 minutes at 75°F. The compound spreads smoothly and can be applied without sagging. It is available in pint, quart, gallon, and 5 gallon kits. For field service applications it can be packaged in premeasured bubble packs.

Master Bond SteelMaster43HT contains no solvents and offers superior dimensional stability. It has a Shore D hardness of 85, a shear strength of > 2,350 psi and a flexural strength of > 6,800 psi. Bond strength to metals, particularly steel and steel alloys, as well as to non-metallic substrates including ceramics and many plastics is excellent.

Master Bond metallic filled epoxy systems are employed in the oil/chemical processing, power, pulp and paper, mining and manufacturing industries. They are designed to provide long-term protection to pumps, offshore structures, valves, pipes, blowers, compressors, engines, etc. These compounds improve efficiency, decrease costs and offer solutions to difficult requirements. Products have advanced capabilities for service in low/high temperature, corrosion, void filling, vibration and load-bearing applications.

Key Benefits of Master Bond Metal Filled Epoxies

Master Bond’s metal filled epoxy compounds feature outstanding performance properties including:

- Convenient cure schedules

- Room temperature curing

- High compressive strength

- Superior chemical resistance

- Long term durability

- Rebuild, reseal worn metal parts

- Readily machinable

- Exceptional adhesion to similar and dissimilar substrates

- Easy to apply

This information has been sourced, reviewed and adapted from materials provided by Master Bond Inc.

For more information on this source, please visit Master Bond Inc.