Quartz filled, two component epoxy adhesive Supreme 45HTQ was developed for high-performance structural bonding applications. It has a 100 to 30 mix ratio by weight and cures in 2-3 hours at 275-325°F. These bonds are resistant to thermal cycling and exposure from -60°F to 450°F. Supreme 45HTQ is 100% reactive and contains no solvents or diluents.

Most noteworthy Supreme 45HTQ has a compressive strength > 20,000 psi and a tensile strength > 8,500 psi. Its Shore D hardness is > 70. Bonds are durable and tough. Adhesion to both similar and dissimilar substrates is excellent. The hardened adhesive has superior electrical insulation properties and its chemical resistance is outstanding.

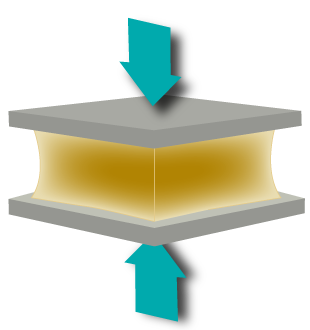

High compressive strength adhesives are of critical importance in many structural bonding applications. Master Bond Inc. has formulated specific grades to resist exposure to hostile environmental conditions. These compounds are available in one and two component systems. Both room temperature and heat-curable products offer unmatched performance and resistance to corrosion and high/low temperatures.

High Compressive Strength Adhesive Systems

Advanced formulations feature outstanding resistance to compressive forces. Products are designed for service in structural bonding applications. Specific grades offer compressive strengths as high as 15,000-20,000 at room temperature.

Key Benefits of Master Bond High Compressive Strength Systems

- Corrosion resistance

- High/low temperature serviceability

- Excellent adhesion to similar and dissimilar substrates

- Easy application

This information has been sourced, reviewed and adapted from materials provided by Master Bond Inc.

For more information on this source, please visit Master Bond Inc.