Sep 27 2012

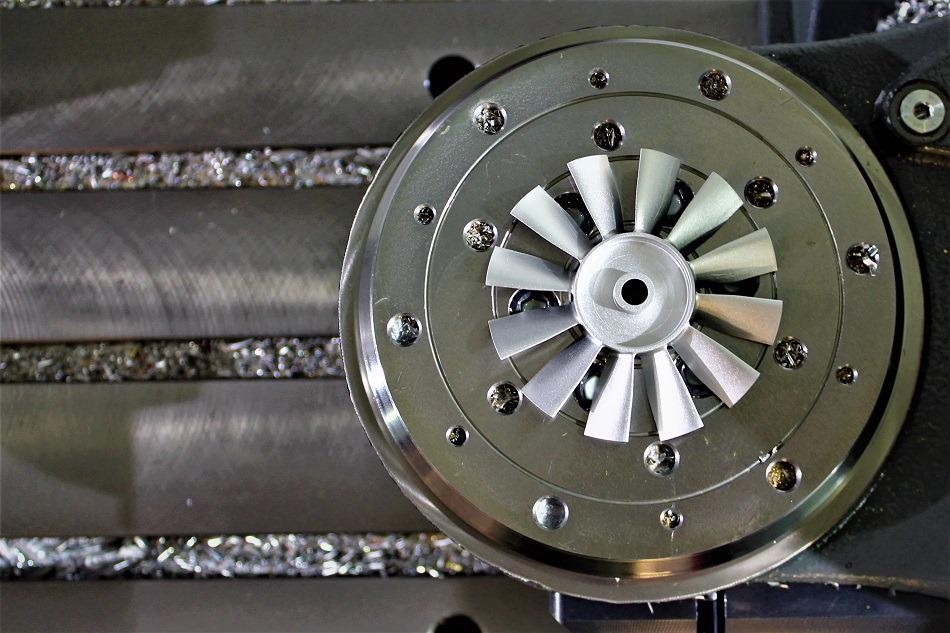

Image Credit: Samuel R Vose/Shutterstock.com

Aluminium / Aluminum alloys are sensitive to high temperatures. They tend to lose some of their strength when exposed to high temperatures of about 200-250°C. However, their strength can be increased at subzero temperatures. They also have good corrosion resistance. Aluminium / Aluminum 6061 alloy is the most commonly available and heat treatable alloy.

The following datasheet gives an overview of Aluminium / Aluminum 6061 alloy.

Chemical Composition

The following table shows the chemical composition of Aluminium / Aluminum 6061 alloy.

| Element |

Content (%) |

| Aluminium / Aluminum, Al |

97.9 |

| Magnesium, Mg |

1 |

| Silicon, Si |

0.60 |

| Copper, Cu |

0.28 |

| Chromium, Cr |

0.20 |

Physical Properties

The physical properties of Aluminium / Aluminum 6061 alloy are outlined in the following table.

| Properties |

Metric |

Imperial |

| Density |

2.7 g/cm3 |

0.0975 lb/in3 |

| Melting point |

588°C |

1090°F |

Mechanical Properties

The mechanical properties of Aluminium / Aluminum 6061 alloy are tabulated below.

| Properties |

Metric |

Imperial |

| Tensile strength |

310 MPa |

45000 psi |

| Yield strength |

276 MPa |

40000 psi |

| Shear strength |

207 MPa |

30000 psi |

| Fatigue strength |

96.5 MPa |

14000 psi |

| Elastic modulus |

68.9 GPa |

10000 ksi |

| Poisson's ratio |

0.33 |

0.33 |

| Elongation |

12-17% |

12-17% |

| Hardness, Brinell |

95 |

95 |

Thermal Properties

The thermal properties of Aluminium / Aluminum 6061 alloy are given in the following table.

| Properties |

Conditions |

| T (ºC) |

Treatment |

| Thermal expansion co-efficient |

23.2 (10-6/ºC) |

20-100 |

- |

| Thermal conductivity |

167 W/mK |

25 |

- |

Other Designations

Other designations that are equivalent to the Aluminium / Aluminum 6061 alloy are listed in the following table.

| AMS 4117 |

ASTM B247 |

ASTM B429 |

DIN 3.3211 |

MIL G-18014 |

QQ A-200/8 |

| ASTM B209 |

ASTM B307 |

ASTM B483 |

MIL A-12545 |

MIL G-18015 |

QQ A-225/8 |

| ASTM B210 |

ASTM B313 |

ASTM B547 |

MIL A-22771 |

MIL P-25995 |

QQ A-250/11 |

| ASTM B211 |

ASTM B316 |

ASTM B548 |

MIL F-17132A |

MIL T-7081 |

QQ A-367 |

| ASTM B221 |

ASTM B345 |

ASTM B632 |

MIL F-18280 |

MIL W-23351 |

QQ A-430 |

| ASTM B234 |

ASTM B361 |

ASTM F467 |

MIL F-39000 |

MIL W-85 |

QQ WW-T-700/6 |

| ASTM B241 |

ASTM B404 |

ASTM F468 |

MIL F-3922 |

QQ A-200/16 |

SAE J454 |

Fabrication and Heat Treatment

Machinability

Aluminium / Aluminum 6061 alloy has good machinability in harder T 4 and T6 tempers. It can be machined in an annealed temper.

Forming

Aluminium / Aluminum 6061 alloy can be easily formed and worked in the annealed condition. The standard methods are used to perform bending, stamping, deep drawing, and spinning operations.

Welding

Aluminium / Aluminum 6061 alloy has excellent weldability. Thinner sections can be welded using the gas tungsten arc welding technique. Heavier sections can be welded using the gas metal arc welding technique. Alloy 4043 filler wire can be used to achieve a good result, but it will affect T 6 properties.

Heat Treatment

Aluminium / Aluminum 6061 alloy is heat-treated at 533°C (990°F) for a sufficient period of time followed by quenching in water. The precipitation hardening process can be performed at 160°C (320°F) for 18 h followed by air cooling. This process is again repeated at 177°C (350°F) for 8 h followed by cooling in air.

Forging

Aluminium / Aluminum 6061 alloy is forged at 233 to 483°C (750 to 900°F).

Hot Working

Aluminium / Aluminum 6061 alloy is hot worked at 260 to 372°C (500 to 700°F).

Cold Working

Aluminium / Aluminum 6061 alloy is cold worked in the O temper condition. It can also be cold-formed in the T 4 and T 6 tempers.

Annealing

Annealing of Aluminium / Aluminum 6061 alloy can be performed at 775°F for 2 to 3 h followed by controlled cooling at 10 to 260°C (50 to 500°F) per hour, and air cooling.

Aging

Aging of Aluminium / Aluminum 6061 alloy can be performed at 177°C (350°F) for 8 h. It is then cooled in air.

Applications

Aluminium / Aluminum 6061 alloy is used in the following applications:

- Truck and marine components

- Furniture

- General structural and high-pressure applications

- Pipelines

- Heavy-duty structures

- Railroad cars

- Tank fittings