Sponsored by XradiaApr 22 2013

From the time the microscope was introduced, scientists and engineers have been developing techniques to observe internal microstructures of samples. The vast majority of such techniques required the sample to be cut or consumed, unable to be observed over time in an environment that is representative of real-world or expected operating conditions. Xradia 3D X-ray microscopes (XRM) achieve submicron resolution in non-destructive in situ studies to image samples in natural states or stressed conditions, enabling critical new research in a broad range of studies from semiconductor failure analysis to materials science.

A new materials science has emerged in which samples are analyzed in situ under relevant conditions. This work has enabled advanced R&D scientific investigations and improvements to material reliability by measuring the structural variation (e.g., shrinking, crack propagation) in the same sample under varying levels of:

- Tensile and compressive stress

- Temperature

- Electrical current

- Pressure

- Chemical environment

- Fluid flow

In situ analysis has developed in all disciplines of microscopy. Past attempts at in situ solutions used two dimensional measurement techniques such as optical or electron microscopy, as well as 2D-based techniques such as serial section electron tomography.

Challenges

There were several challenges to be faced as far as in situ analysis is concerned. These include:

- Sample preparation: Cutting to view the interior creates an artificial geometry, which can give unrealistic measurements of the effects of external stresses such as compression, temperature, etc.

- Induced damage: The removal of layers for surface imaging can expose sensitive internal structures to the environment or, worse, eliminate features before imaging

- Imaging in a vacuum: This may prevent observation of the sample under the effects of its intended environment

- Consumption of sample: The removal of layers to image destroys the sample, denying subsequent 4D (3D + time) studies on the same region of interest

X-ray micro computed tomography systems (microCT) resolved many of the problems in previous in situ techniques as the systems are non-destructive, 3D, and required little to no sample preparation. Conventional laboratory X-ray technology, however, is limited to coarse resolutions at working distances that cannot accommodate in situ environmental chambers.

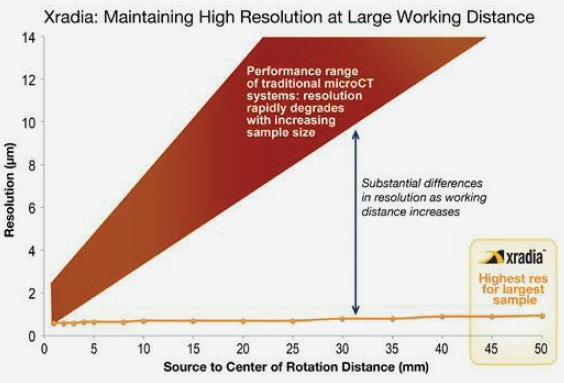

Xradia XRM resolves the limitations of traditional microCT by providing the highest resolution at the largest working distance. Thus high resolution is maintained even for imaging samples inside in-situ environmental chambers.

Application Examples: Crack Propagation

Rat Mandible Study: In Situ Compression Study

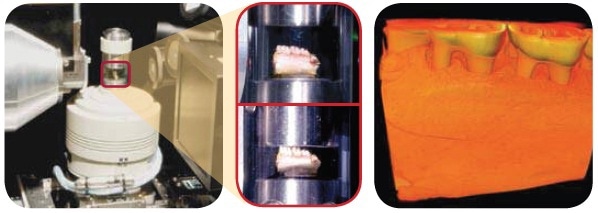

A mandible was placed inside a tensile loading rig within the MicroXCT-400 and scanned while undergoing compression to examine crack initiation and propagation. Sample courtesy of Sunita Ho, University of California San Francisco

Figure 1. Rat mandible study: In situ compression study

Hydration Study

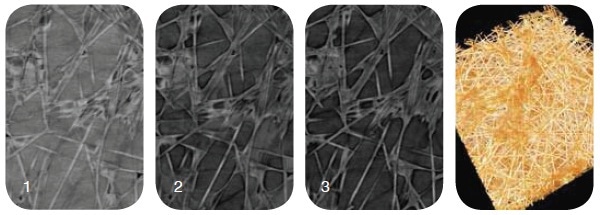

Hydrated Carbon Fiber: 4D evaporation study was done wherein scans were performed over time noting evolution of structure as water evaporates. Scan 1: T=0 Scan 2: after 3 hours Scan 3: after 8 hours Far right: volume rendering of third scan Sample courtesy of Dr. Ugur Pasaogullari, University of Connecticut

Figure 2. Hydrated Carbon Fiber: 4D evaporation study

Enabling a New Class of Material Science

The ability to perform in situ studies and, moreover, perform them at high submicron resolution in 3D, enables a new, unprecedented capability for a variety of studies.

This is required for new discoveries in:

- Microstructural evolution observation to measure the impact of conditions on structure over time; these studies require a non-destructive imaging solution so that the sample can be repeatedly imaged to observe such developments as crack propagation or grain growth

- Failure analysis studies, as semiconductor chips that appear structurally intact upon manufacture may crack or deform due to the heat of operation. Imaging under thermal stress may reveal weak interfaces.

- Permeability studies used in unconventional gas exploration must assess changes in microscopic fluid flow as well as structural evolution as samples become hydrated, or experience temperature and compression changes

- In biomimetics, artificial materials that mimic naturally occurring materials must be analyzed under similar conditions because the environment can dramatically impact properties; e.g., to reproduce the lightness and strength of wood, mechanisms behind the significant difference in tensile loading strength of wood fibers under hydrated and dry conditions must be understood;

Figure 3. Highest resolution at the largest working distance from the source, a prerequisite for in situ and large sample imaging

Solutions by Xradia

Spatial resolution, image contrast, and working distance are the major parameters characterizing the performance of an X-ray microscope. Xradia offers the VersaXRM and UltraXRM 3D X-ray microscopes with world-class performance in all three parameters:

- Multi-scale imaging with resolution down to 50nm

- Phase contrast imaging technology for low contrast features

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.