Sponsored by XradiaApr 22 2013

The building industry is suffering a loss of roughly $500 million every year because of early stage cracking in concrete materials, of which 50% of the problem taking place at field construction sites. Better understanding the reasons behind cracking in cement-based building materials is a subject of intense research and investment in both industry and academia. Moreover, thousands of lives can be saved during natural disasters if the mechanisms behind concrete cracking and subsequent failure are clearly understood.

The following are some of the several mechanisms that induce cracking in building materials:

- Longer-term cracking caused by internal chemical origins (such as rebar corrosion) or mechanical stress

- Excess heat generation or lack of moisture during the preliminary stages of curing

Since the crack mechanisms are huge in number, it is a challenge to characterize the highly varying 3D topologies of crack networks.

Limitations of Traditional Techniques

The lack of resolution and the intricacy of the 3D nature of cracking have limited conventional techniques to gain insight into the sources and impact of cracking. Low resolution (from 100 µm to several mm) acoustic and common 3D X-ray methods such as micro-computed tomography (micro-CT) are able to provide data on macro-crack structure.

High resolution can be obtained with a few sophisticated traditional micro-CTs, but on very limited sample sizes. Many other high resolution analyses have utilized SEM or optical imaging of individual slices of the material. However, this approach is inherently destructive, thus limiting the valuable data to only 2D surface views.

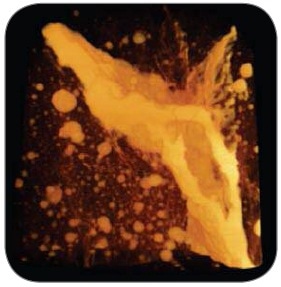

Figure 1. Inversion of a region of interest in concrete to highlight the cracks and voids

3D X-Ray Microscopes (XRM) from Xradia

To address the shortcomings of existing imaging techniques in detecting crack geometry and mechanisms, Xradia offers the VersaXRM 3D X-ray microscopes with non-destructive submicron true spatial resolution to perform 3D crack morphology imaging. With submicron 3D resolution, the VersaXRM can acquire data on the complex characteristics of cracks in comparatively large sample sizes. The VersaXRM’s two-stage magnification system provides high resolution at large working distances.

The following are the key advantages provided by the VersaXRM for imaging cracks in building materials:

- Superior Contrast – The proprietary Phase Enhanced detectors in the VersaXRM deliver superior contrast to differentiate various phases within building materials. The system highlights fracture interfaces by implementing propagation phase contrast.

- Submicron Resolution – Provides down to submicron (<0.7 µm) spatial resolution to capture images of hairline fractures and those in the proximity of the crack tip.

- In situ and 4D Capabilities for Fracture Mechanism Identification – The use of optical and geometric magnification enables the VersaXRM to overcome the conventional resolution shortcomings of projection based systems, thus maintaining high resolution even at large distances and enabling non-destructive, high-resolution imaging of samples within in situ chambers. Moreover, it is possible to repeatedly measure crack network evolution under stress and/or environmental conditions in order to quantify and correlate cracking within the same sample under different conditions.

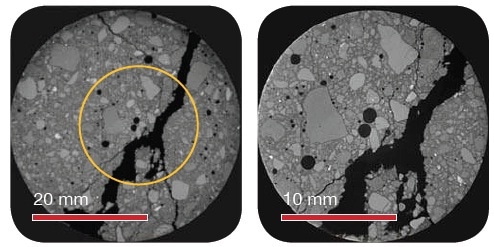

The results of a subarea imaging of a failed 50 mm concrete specimen are shown in Figure 2. Two scans were conducted, of which one is at 20 µm voxel size resolution with a field of view (FOV) of 40 mm and second is at 10 µm voxel size resolution with an FOV of 20 mm. The 20 µm voxel scan provides a valuable overview of the whole crack structure and the 10 µm voxel scan provides details of any subregion of the sample.

Figure 2. Various images showing 20 µm voxel resolution (40mm FOV) on the left and 10 µm voxel size (20 mm FOV) on the right. Both scans were taken on the same, intact, 50 mm sample

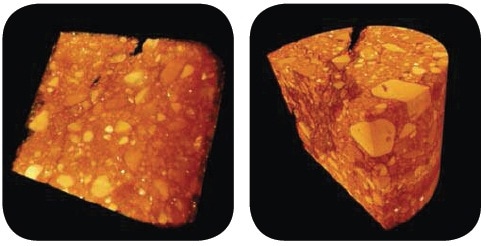

Three-dimensional view of the same images is shown in Figure 3.

Figure 3. Three-dimensional view of same images

Conclusion

The combination of the VersaXRM’s high resolution and unique architecture provides comprehensive data on the crack morphology of samples devoid of destructively reducing their size. This technique is suitable for time-dependent studies in which the same sample is subjected to increasing levels of load and the same subregion is imaged to enable the thorough analysis of crack initiation and propagation.

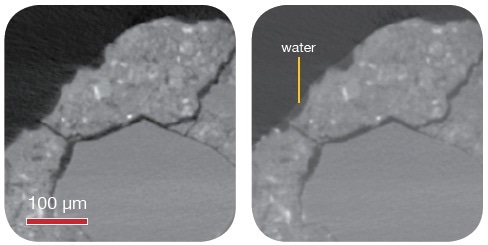

Figure 4. 4D study under environmental conditions. High contrast enables view of wetting effect

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.