Bonding is a surface phenomenon and the bonding surfaces of the materials to be bonded need to be compatible at the molecular level. However, compatibility may not be there between the two bonding surfaces due to physical or chemical barrier between the surfaces. If the barrier negatively affects the bonding between surfaces, then bonding becomes complex or impossible.

Physical and chemical barriers on surfaces are imparted during production processes such as heat treatment, chemical cleaning and protective processes such as the application of corrosion inhibitors. For instance, in a die casting process, lubricants are used by die caster for releasing castings from the die. The lubricant avoids the sticking of the metal of the casting to the metal of the die. The presence of any excess lubricant can cause adhesion problems on the surface of the diecast.

Corrosion Testing and Consulting at Element Wixom

Element Wixom offers corrosion and metallurgical testing and consulting services, covering all areas of corrosion, including localized, uniform, metallurgically-influenced, microbiologically-influenced, environmentally-induced, and mechanically-assisted cracking. Moreover, the company provides expert analysis and litigation support on corrosion and metallurgical engineering problems prior to courts and allows its facilities to be utilized for testing by defendants and plaintiffs.

Failure Analysis of Nonbonding of a Powder Coat

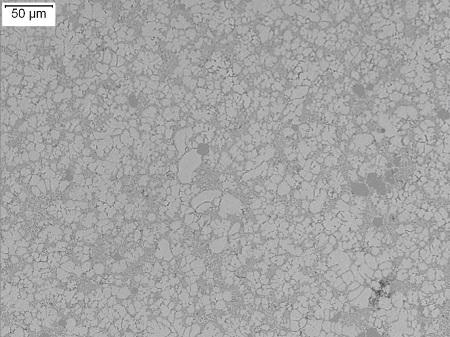

The bonding of a powder coat to a surface demands a superior adhesion between the powder coat and the surface. The presence of a contaminant on the surface would affect the bonding of the powder coat to the surface because the contaminant may act as a barrier to the bonding. As shown in Figure 1, an aluminum diecast component from a new diecast supplier was not able to bond to a powder coat that was applied to the surface of the diecast. The presence of a contaminant that was applied by the supplier to the surface was suspected as the reason for nonbonding.

Figure 1. Aluminum diecast part

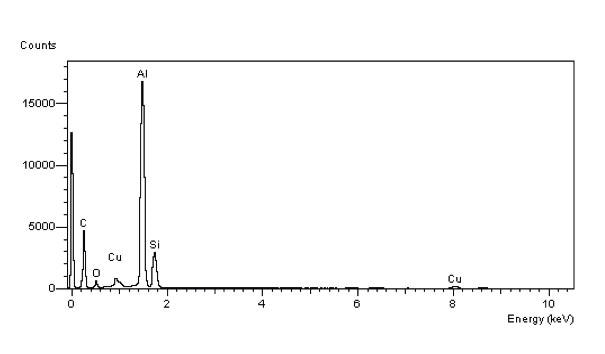

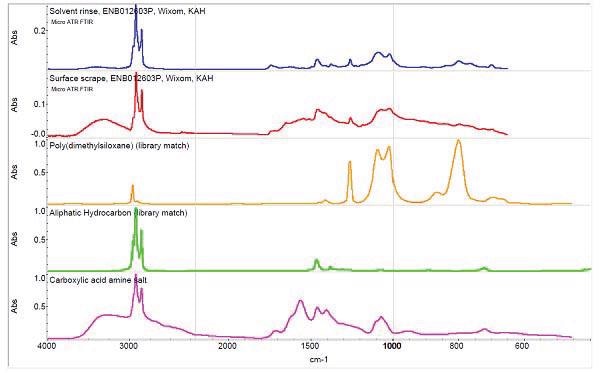

Element Wixom believed that the presence of organic acid salts, hydrocarbon oils, and silicone on the aluminum diecast surface was the reason for the nonbonding of the powder coat to the surface of the diecast. Organic acid salts are normally found in surfactants, anti-corrosion products, lubricants, and soaps. Organic acid salts, hydrocarbon oils, and silicone are known to hinder bonding on surfaces. Selected test results are shown in Figures 2, 3, and 4.

Figure 2. Optical micrograph (as-polished) of aluminum diecast sample microstructure. Original Magnification = 200X

Figure 3. Typical EDS spectrum of aluminum diecast sample surface (as received)

Figure 4. Typical FTIR spectra of residue from Aluminum diecast sample surface (as received) and some compounds.

Fatigue and Fracture In Environment - Short Version with Subtitles

Video Credit: Element Materials Technology

This information has been sourced, reviewed and adapted from materials provided by Element Materials Technology.

For more information on this source, please visit Element Materials Technology.