Downgauging or lightweighting is an important cost concern for all packaging manufacturers. Lightweighting is achieved by reducing the raw material volume used in packaging. It is important that using less raw materials does not result in poor quality, weaker containers that fail and collapse during their life cycle. Top-load testing is one of the most accurate methods for reliably determining container integrity.

Manufacturers of all kinds of containers especially plastic must ensure that products can withstand the expected forces they will experience during the capping or filling process and warehouse stacking.

Since Mecmesin understands the necessity and importance of downgauging or lightweighting, a range of affordable top load testers has been developed to help manufacturers test their products for ‘axial load strength’ in accordance with international and industry standards.

Compliance with Standards

Below is a selection of the standards regulating top-load (axial load strength) testing that includes the following:

- ASTM D2659-11- Standard test method for column crush properties of blown thermoplastic containers.

- ASTM D642-00 (2010) - Standard test method for determining compressive resistance of shipping containers, components, and unit loads.

- ASTM D4577-05 (2010) Standard test method for compression resistance of a container under constant load.

- ASTM D4169-09 Standard practice for performance.

- Testing of shipping containers and systems.

- ISBT plastic bottle test methods 2004.

- ISO 8113:2004 Glass containers - resistance to vertical load - test method.

- DIN 55440-1:1991-11 Packaging test; compression test; test with a constant conveyance-speed.

- DIN 55526-1 packaging test; compression test; dynamical test for plastic containers, with a capacity up to 10 liters.

- DIN 53757:1977-08 Testing of Plastics Articles -determination of the behaviour by stacking using a long-time-test, and Boxes for Transport and Storage.

Configuration of Mecmesin’s Range of Top-Load Testers

The versatility and power of Mecmesin’s range of Top-load Testers make them suitable for testing both ‘axial load strength’ and ‘bottle height, all in a single affordable instrument. The most popular model for top load testing is the ‘MultiTest 5-xt’ (Superseded by the OmniTest Touch 5), which can apply forces up to 5000N (1100lbf, 500kgf) - enough for small and medium-sized containers. It is operated using a simple-to-use touchscreen and fits neatly on most production lines or laboratory benches.

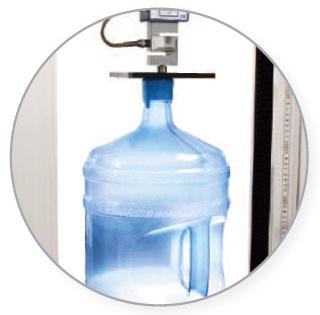

Figure 1. Configuration of top-load tester.

Key Features and Configuration

The key features of the Mecmesin’s range of top-load testers are:

- Quick-and-easy operation - ideal for all operators at all skill-levels.

- Immediate operator access to five pre-set favourite tests.

- Results displayed clearly color-coded as ‘Pass/Fail’.

- Password-protected login for operators to ensure full traceability.

- Automatic report generation that is customizable to suit your needs.

- Measure peak compressive strength.

- Measure load at a specified deflection and measure bottle-height.

The configuration of the top-load tester is as follows:

- Rugged construction enables testing of various heights of container.

- Easy-to-use touchscreen panel for test selection and storage/export of test data.

- USB ports enable data-transfer to an external PC or network for integration into a Statistical Process Control (SPC) System.

- Variable-speed crosshead makes testing possible at the user's choice of speed.

- For more sophisticated test routines simply create your own programmes.

- Loadcell provides top-load force of 5000N (1100lbf, 500kgf) - ideal for most containers.

- Dedicated compression plates for top-load testing of standard, oversized or irregular containers.

Capacity and Affordability

Which Tester to Choose?

Figures 5, 6 and 7 show different types of testing:

Figure 2. Crush test on cardboard packaging using a Multi Test 10-i top-load tester (Superseded by OmniTest 10).

Figure 3. Top load test on a water cooler bottle.

Figure 4. Top-load test on a PET bottle using a Multi-Test 2.5 xt top-load tester. (Superseded by OmniTest Touch 2.5)

The parameters to be considered are as follows:

- Larger samples, higher capacity – Test systems vary based on capacity. Larger containers may not have a high compressive strength but they might need the physically greater dimensions of a twin-column frame. Alternatively, containers with high compressive strength, such as cardboard cartons, might not be large but will require the high capacity that a twin-column tester provides - up to 25kN (5500lbf).

- Loadcells – Containers have a varying strength so load cells come in a range of capacities to perfectly suit the range of forces being applied. The loadcell is simply fitted to the test frame and recognizing its calibration data is instantaneous and automatic.

- Smaller samples, lower capacity – Most commonly used containers can be tested with a single-column top-load tester with models available rated up to a capacity of 5kN (1100lbf). This range of testers fit neatly onto a laboratory or production line bench and is an excellent value-for-money investment.

Mecmesin offers a range of standard and custom fixtures to meet your top-load testing requirements:

- Vented Compression Plate (with nose cone)

- Slotted Compression Plate

- Circular Compression Plate

- Square Compression Plate.

Conclusion

Mecmesin test systems are used worldwide by bottlers for multi-national beverage companies, and are well known for their multiple benefits and affordability including:

- Economy - ensuring consistency in product quality and minimizing material wastage and expense.

- Practicality - designed with the production floor in mind.

- Usability - single push-button operability for quick and easy use by any operator.

- Versatility - a single test system performs two functions: bottle-height testing and top-load testing.

- Investment in quality-control equipment and minimizes training time.

- Compactness and portability - fits on a bench-top, providing the flexibility to locate the tester where it best suits you.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.