Almost all particulate solids are surface characterized (BET surface area and particle size) from a physical chemistry perspective. This must be compared with in-depth analytical chemical data such as the chemical structure and morphology obtained by means of GC-Ms, XRD, FTIR, and NMR. Nevertheless, the thermodynamic state of the material cannot be known from any of these acquired data.

Surface Energy

Surface energy (Y) has now been established as a key property of a particulate or powdered material by researchers, and can be measured with the iGC SEA. The quantification of attractive intermolecular forces within a solid provides its surface energy - an analogous value to a liquid’s surface tension.

These intermolecular forces are the cause of the attraction among solids such as powder particles, vapor species and liquids, occurring through short range chemical forces (polar forces) and long range van der Waals forces.

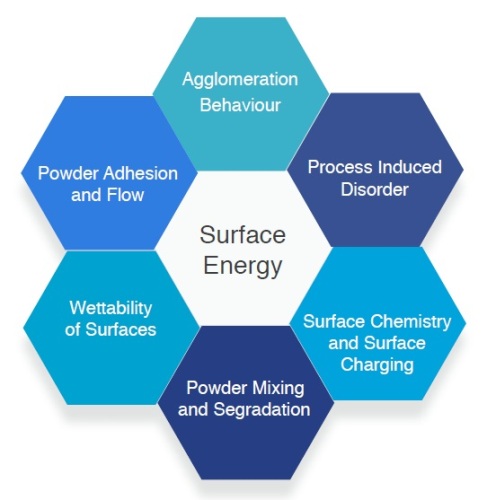

Hence, surface energy is related to several key properties of solids such as surface chemistry, adsorption capacity, static charge, adhesion, process-induced disorder, agglomeration, powder flowability, dispersability, and wetting (Figure 1).

Figure 1. Surface energy values (dispersive and polar) correlate to several key solids properties

iGC (Inverse Gas Chromatography) Surface Energy Analyzer (SEA)

iGC SEAs measure the surface energy of a solid by subjecting the solid sample to vapor probes of known properties and investigating the interface between the surface of the solid and other molecules. The sample’s total surface energy can be measured by analyzing the intermolecular forces caused by this interaction.

The surface energy of solid particulate materials can be measured by means of a variety of techniques. The most common method is the contact angle measurement, but its application for particulates is difficult due to its unreliability and inaccuracy.

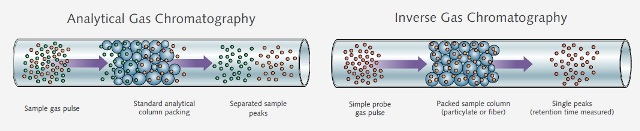

Using the gas-phase technique, iGC, surface and bulk properties of particulates, powders, films, fibers and semi- solids can be characterized. Vapor pulses are injected into a column consisting of the powdered sample being analyzed. In iGC, the unknown powder sample is characterized using vapor probes - a different approach when compared to classical analytical gas chromatography (Figure 2).

Figure 2. Comparison of analytical gas chromatography and inverse gas chromatography

The typical sample size is 5-100mg and it only takes a few minutes to pack the sample into a glass column. The retention (adsorption) of the vapors by the particulate materials is measured subsequent to automated elution of various organic vapors through the column.

The fully automated SEA can determine a broad range of bulk and surface properties of the sample by varying the solvent vapor, temperature, flow rate, and column conditions. The following table compares the inverse gas chromatography with other methods:

| Inverse Gas Chromatography |

Atomic Force Microscope |

Contact Angle |

Wetting Balance |

| Ok for flat surfaces. |

Ok for flat surfaces. |

Excellent for flat surfaces. |

Excellent for flat surfaces. |

| Excellent for particulates - repeatable, no-hysteresis or roughness effects. |

Not well suitable for particulates - slow and poor data statistics. |

Not suitable for particulates - swelling, hysteresis, dissolution, surface roughness. |

Not suitable for particulates - swelling, hysteresis, dissolution, surface roughness. |

| Wide range of solutes possible and heterogeneity can also be mapped. |

Theory for determining surface energy can be complex |

Very few solutes possible. |

Very few solutes possible. |

| Can measure vapor adsorption isotherms as well as surface energy. |

|

|

|

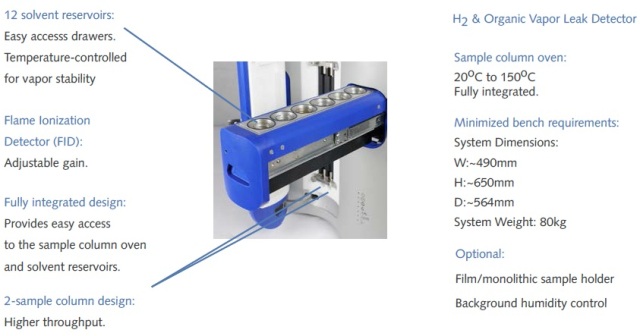

SEA Hardware and Software

The patented injection manifold system (Figure 3) with an injection volume ratio of 1:4000 is the key component of the SEA and produces accurate sizes of solvent pulses across a wide range. This causes isotherms at low and high sample surface coverages and therefore surface energy heterogeneity distributions can be determined accurately.

Figure 3. The unique variable injection system

The experimental flexibility of the iGC SEA is harnessed by the SEA software, which delivers comprehensive and easy-to-use data analysis as well as one-click report generation. Cirrus Plus allows efficient use of the iGC data acquired.

The standard features are given below:

- Surface energy analysis

- Isotherm determination/BET/Henry constant

- Surface heterogeneity mapping

- Acid-Base Chemistry analysis

- Competitive sorption measurement

- Work of adhesion/cohesion determination

- Heats of adsorption/sorption measurement

The following are the advanced features:

- Work of cohesion and adhesion

- Crosslink density

- 1-D and 3-D solubility parameters

- Glass transition temperature

Applications of iGC SEA

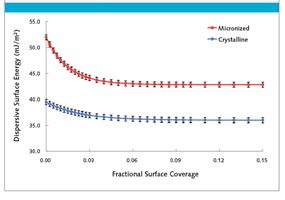

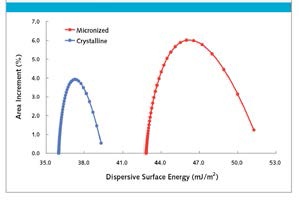

Surface energy heterogeneity profiling is possible with iGC SEA. Figures 4 and 5 present the dispersive surface energy distributions for budesonide samples and dispersive surface energy profiles for budesonide samples, respectively.

Figure 4. Dispersive surface energy distributions budesonide samples

Figure 5. Dispersive surface energy profiles budesonide samples

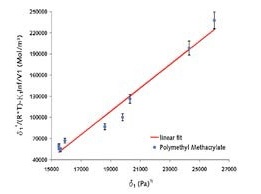

Solubility parameters (Hildebrandt and Hansen) can be determined as shown in Figure 6.

Figure 6. Hidebrandt solubility parameter for polymethyl methacrylate

Other applications include

- Adsorption isotherms, heats of adsorption and Henry constants

- Dispersive, polar and acid-base surface energy/chemistry

- Works of adhesion and cohesion