The Kratos Ar Gas Cluster Ion Source (GCIS) is ideal for depth profiling inorganic materials in Ar+ monomer mode and organic materials in Arn+ cluster mode, according to the operating parameters established by the user and the type of material to be profiled.

The ions can be accelerated up to a maximum of 20 keV in the Arn+ ion cluster mode, which enables the successful sputter depth profiling of the broadest range of polymer materials to be attempted. However, Arn+ cluster depth profiling is capable of offering very low sputter yields for inorganic materials. To retain the capacity of generating depth profiles from this class of materials, this ion source can also be operated in the more traditional Ar monomer (Ar+) mode.

Recent developments in depth profiling of organic materials are based on sputtering, with large Arn+ ion clusters comprising of hundreds or even thousands of Ar atoms.

In contrast to monatomic ions, large cluster ions do not penetrate deeply into the material, modelling showing that the energy of the impact is deposited within the first few nanometers of the surface. As the energy is shared by all atoms in the cluster, the energy per projectile atom, or partition energy, can be as low as a few electron volts, so that the cluster ions only sputter material from the near-surface region, leaving the subsurface layer untouched.

Hardware

The Ar GCIS can be mounted on a DN64 (4.5" OD) flange, with a working distance suitable for both the AXIS Supra and AXIS Nova photoelectron spectrometers. The GCIS is differentially pumped with two dedicated turbomolecular pumps, supported by an oil-free scroll pump, with extra pumping provided by the sample entry chamber.

A two degree bend is added into the ion beam column to eliminate high energy neutrals from the beam, as these particles can considerably reduce interface resolution during depth profiling due to their greater penetration depth into the sample. Valves, gas pressure, and operating parameters are all controlled via the acquisition software.

Ar Gas Cluster Operating Mode

Large Ar clusters develop through the isentropic adiabatic cooling of the gas as it expands from high pressure into the vacuum of the source region via a de Laval nozzle. The Ar clusters are ionized by electron impact and accelerated down the ion column. A Wien velocity filter is used to taper the sampled range of cluster size. The ions are accelerated up to a maximum of 20 keV (Ar+ cluster mode) or 5 keV (Ar+ monomer) with a series of lenses, in order to focus and quadrupole scan plates to raster the ion spot across the surface of the specimen.

The median cluster size is established by setting the appropriate electric field on the Wien filter. The cluster sizes used can be differed from Ar500+ to Ar2000+ so that the partition energy can be varied from 2.5 eV (eg 2.5 keV/1000 cluster etc) to 40 eV per Ar atom.

Ar Monatomic Operating Mode

The ion source can also be operated in the more traditional monatomic Ar+ mode, which is more appropriate to depth profiling inorganic samples. Research has revealed that the sputter yield of this class of sample is very low when using Ar clusters, so it is vital to be able to sputter using Ar+ ions. Switching to Ar monomer mode involves simply choosing the suitable table entry in the acquisition software.

He Monatomic Operating Mode

The GCIS is also designed to operate with monomer He+ for ion scattering spectroscopy (ISS) experiments. Ion scattering spectroscopy is the spectrometer’s optional operating mode. In this mode, the ion source is operated at very low ion beam currents to stay below the static limit.

Software

Full control of the Ar GCIS is facilitated by the acquisition software. Operating parameters are stored in a table that can be used to re-establish the optimized conditions before using the source. During use, the status of the GCIS may be monitored to follow the working parameters of the source. These parameters may also be stored to a log file; enabling extended monitoring of the GCIS’ operating conditions.

Control of the gas flow needed for operation of the GCIS is easily realized with the automatic sequences in the vacuum control section of the acquisition software. Full automation of the gas handling system means that the GCIS can be operated remotely, or unattended. Control of separate valves, pumps, and gauges may also be taken up using the vacuum mimic diagram and the 'safe manual' mode.

Download the Brochure for More Information

Applications

Maximum Flexibility

Published research1 has demonstrated that various types of polymers have different sputter yields, dependent on varied cluster size and energy. To attain highest flexibility in terms of the range of materials which can be effectively profiled, the ion source parameters, including primary beam energy and cluster size, can be defined specially to optimize sputter yield of the specimen under analysis.

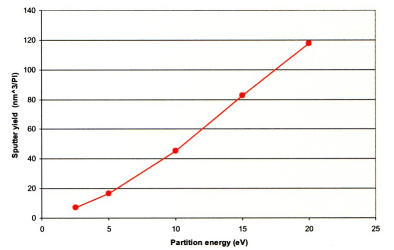

Data gained using the GCIS Arn+ [Figure 1] illustrates that the sputter yield of poly(lactic co glycolic acid), PLGA, is very reliant upon the primary beam energy. Moreover, it is obvious that the capability to produce ions with 20 keV energy causes greater ion yield for PLGA.

Figure 1. Sputter yields for Ar1000+ at a range of primary beam energies on 60nm thin film PLGA polymer on Si

Organic/Organic Multilayer Depth Profile (Ar500+)

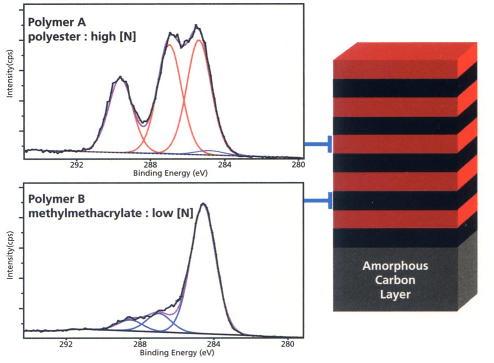

The following example is a sputter depth profile via an organic/organic multilayer sample, with 10 alternating layers of polyester containing a high nitrogen concentration, and a methylmethacrylate with low nitrogen concentration, where each polymer layer is nominally 100 nm thick. The sample is illustrated as a schematic diagram in Figure 2.

Figure 2. Polymer / polymer multilayer and representative spectra from each layer

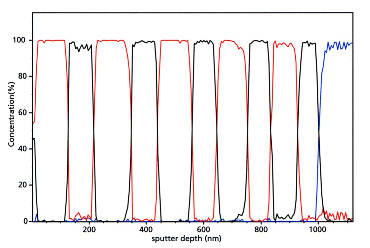

Data was gained from a 110 µm analysis area, centred in a 1.5 x 1.5 mm2 sputter crater. The GCIS was applied in cluster mode, with Ar500+ accelerated to 5 keV, offering partition energy of 10 eV per atom. The concentration depth profile is illustrated in Figure 3 with the carbon chemical state plotted against sputter depth. It is instantly clear that the sputter yield for both polymers is similar under the ion source parameters used, providing an average etch rate of 18.5 nm/min for the bilayers.

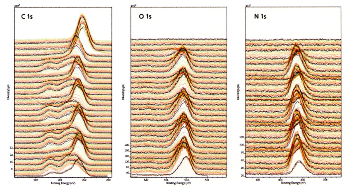

It is also noted that outstanding interface resolution is maintained during the profile, with the interface resolution between polymer layers 9 and 10 measured as 15 nm. Figure 4 illustrates the narrow region scans for C 1s, O 1s, and N 1s as an operation of sputter cycle. This demonstrates that the chemistry of both polymers is retained throughout the depth profile.

Figure 3. C 1s chemical state depth profile for polymer/polymer multilayer

Figure 4. High resolution, narrow region scans for C 1s, O 1s and N 1s regions as a function of sputter cycle. The 'as introduced' surface is at the bottom of the figure, with increasing etch time vertically to the bulk amorphous carbon substrate at the top of each plot.