Simulated moving bed chromatography (SMBC) is a continuous chromatography system that enables binary or pseudo-binary mixtures to be separated into pure fractions or substances.

In contrast to traditional batch chromatography, this process results in higher yields of purified substances while consuming less eluent and packing material.

How Does Simulated Moving Bed (SMB) Chromatography Work?

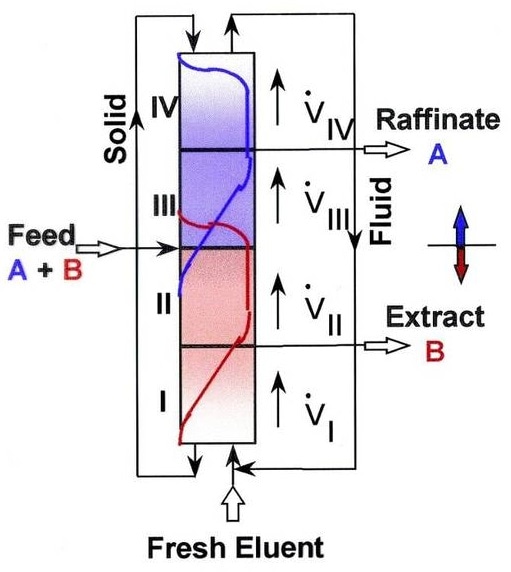

In contrast to batch chromatography, in a SMB process the liquid phase is in motion and the solid phase moves in counter-current mode to the liquid phase. Simultaneously, the individual areas are operated with varying volume currents. The concept that is shown in figure 1 is the classic four zone version SMB configuration.

The separation zones are zones 2 and 3. In zones 1 and 4, the liquid or alternatively the solid phase is regenerated. The feed (component A + B) is fed in the middle of the demonstrated “SMB column”.

The liquid phase (eluent or desorbent) moves from the bottom to the top and transports component A (blue). Component A is nonstop led out of the system in the raffinate as a pure substance. The solid phase (solid) moves from the top to the bottom and transports component B (red). Component B is pure when it is guided out of the system as an extract. The distribution of both components over the whole column system is easily recognized by the concentration profile.

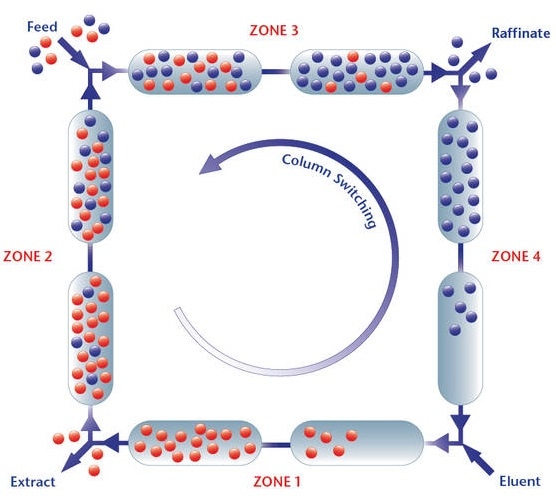

The movement of the solid phase is attained by linking a certain number of columns in series in a closed circuit and by switching the columns counter-clockwise in defined time intervals one position upstream.

The build-up of the process is schematically illustrated in figure 2. Four pumps are combined into the system. Two pumps are used for the add-on of fresh eluent and feed and two pumps are used for the upkeep of the internal flow. Based on need, normally 8, 12, or 16 columns are used. In general, the columns are equally spread in the individual zones (e.g. 2/2/2/2). However, based on the separation problem, they can be asymmetrically spread (e.g. 1/3/3/1). Besides the four zones, concepts with three, five or eight zones can also be attained.

The latter two can be drawn for a three component separation. It is also possible to separate intricate mixtures into two valuable substance fractions (pseudo-components).

In traditional chromatographic separations with single column, only a small part of the column takes part in the separation, while the main part does not make a contribution to the output. In a SMB process, the entire column bed is efficiently used. When all volume currents are enhanced, a stationary state is created. In other words, the middle concentrations of the purified extract and raffinate currents do not change any longer. The system can be constantly operated under these conditions.

At first SMB was used to divide xylene isomers in the oil refining industry because they could not be effectively divided by means of distillation. Of late, this technology has been established and is employed in the sugar industry, for the production of pharmaceutical ingredients and in chiral separations.

AZURA® Lab SMB System

The AZURA® Lab SMB System from Knauer is enhanced for the separation of binary mixtures in gram-scale. This system can be configured especially for needs such as optimization for high flow rate (50 ml/min) or high pressure (400 bar).

Download the Datasheet for More Information

Download the Datasheet for More Information

AZURA® Pilot SMB System

The AZURA® Pilot SMB System from Knauer is designed to purify up to several hundred grams of binary mixtures per day with a flow rate up to 500 ml/min. Configuration with six or more columns are available.

Download the Datasheet for More Information

Download the Datasheet for More Information