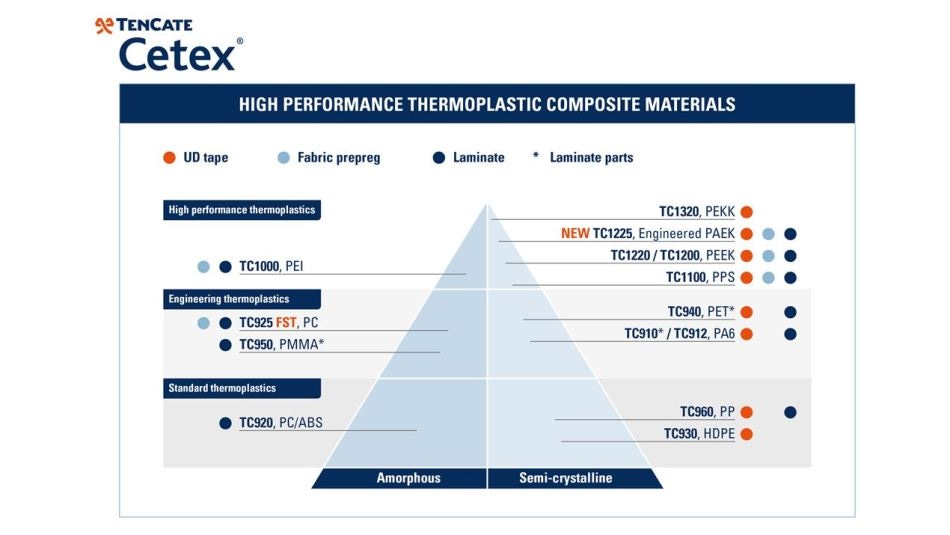

Toray unidirectional (UD) tapes and thermoplastic prepreg are skillfully designed innovative composite materials, offered in a comprehensive variety of fiber/resin blends, complying with the stringent specifications of large aerospace OEMs.

The fiber alignment and resin distribution of thermoplastic Cetex® materials of Toray are uniquely predictable. They are developed for press molding, in situ compaction, and manufacturing of autoclaves. These distinctive features make the materials of Toray perfect choice for huge parts, while reducing total cost and shortening the process.

Toray have over 40 years of experience in creating custom industrial and aerospace UD, and prepreg solutions at their premises. These materials deliver exceptional chemical resistance, durability, mechanical and fire performance meeting an array of industrial requirements.

Processing UD tapes

Advanced fiber placement (AFP)

AFP is a technique which utilizes computer-aided robotics to apply one or more layers of UD tape over a mold to form a structure. During this process, laser, IR, or hot gas is used for heating the UD-tape. Using a cold roller, the heated tape is bonded in-situ to the rest of the assembled structure. The quality of UD tape is of paramount importance. Major applications include fuselages and skins of aircraft wings.

Automated tape lying (ATL)

The UD-tapes are placed in a 2D blank, in the chosen stacking arrangement. Employing thermal or ultrasonic welding, each new piece of UD-tape is attached to the layer below. The final 2D structure can be additionally compacted or directly created to make the desired structure, depending on the capability of the machine. During this compaction step, individual layers are completely bonded together. Impregnation quality dictates the speed of this process.

Wrapping

The process of applying UD tape over cylindrical parts such as piping and tanks is termed as wrapping. The outstanding erosion resistance and loop reinforcement strength of Cetex® thermoplastic composites of Toray make it appropriate for lightweight tanks and spoolable piping.

Thermoformable

The high compaction quality of Cetex® thermoplastic composites of Toray in both RTL and UD tape formats permit simple ‘heating and forming processes’ which only takes minutes to complete.