The compact EASYHEAT induction heating systems from Ambrell are a dependable solution for heating parts with a fast, clean source of heat. With a movable work head that can be positioned up to 3 m (10’) from the power supply, it is suitable for repeatable, non-contact heating of parts.

Designed to work over a broad frequency range (150-400 kHz), the EASYHEAT is perfect for heating parts of many compositions and geometries with precise power control within 25 W resolution. Time-consuming changeovers can be avoided with agile tuning for single-cycle and continuous heating operations. One system is capable of supplying deep, bulk heating for brazing and soldering for more shallow, concentrated heating for case-hardening for smaller parts. Flameless, non-contact induction heating reduces energy waste by directing energy only on the part and zone to be heated.

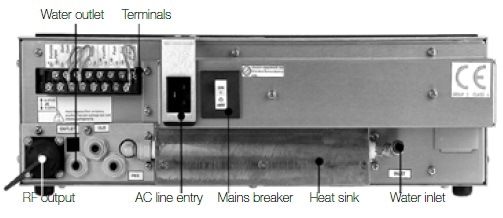

Power levels can be selected and monitored from the front panel LCD and sealed touchpad. Remote power control is available for employing analog inputs, contact inputs, or optional serial data port. A built-in programmable digital timer enables easy control of the length of the heating cycle. The EASYHEAT is a water-cooled system that requires connection to a heat exchanger or other means for dissipating heat.

Versatile

- Efficient heating of many geometries

- Five language display suite (EN, FR, IT, DE, ES)

- Repeatable, reliable heating with agile frequency tuning

- Field-calibration capable

- Movable workhead; up to 3m (10')

- Remote serial operation or logging (optional)

Easy-to-Use

- Push-button RF power control

- View set-point, output, frequency, and timer

- Self-adjusting for accurate, repeatable results

- Built-in timer, stop-watch

Compact and Light

- Smallest feature-filled 2.4 kW model

The EASYHEAT has a front panel programmable controller that allows users to define up to four different heating profiles, each with up to five times/power steps.

Options and Accessories

- Start-up assistance

- External controller (plc)

- Heat exchanger or chiller

- Serial data interface

- Pendant station

- Footswitch

- Extended work head cable lengths

- Optical pyrometer (closed-loop temperature control)

Specifications

| Specification |

0112 |

0224 |

UNITS |

| RF Terminal Power |

1.2 |

2.4 |

kW |

| AC Line Power |

1.6 |

3.3 |

kVA |

| AC Line Protection |

15 |

15 |

A |

| Frequency |

150-400 |

kHz |

| RF Coil Current |

300-400 |

A max |

| AC Line Voltage |

117 or 220 |

220 |

Vac ± 10%, 1Ø |

| Front Panel Display |

2 line x 16 character LCD; displays frequency, power, setpoint, timer and fault descriptions |

|

| Display Language Suite1 |

Five language display suite (EN, FR, IT, DE, ES) |

|

| Serial Communications |

Via RS485 terminal mode |

Optional |

| Timer |

Built in; 10ms to 10,000 seconds |

|

| Heating Controller |

4 programmable profiles, 5 steps per profile |

|

| RF Rise Time |

<5 |

ms |

| Tune Time |

<5 |

ms |

| Compliance |

CE Marked, 220 models only |

|

| Max Ambient Temp |

45 (115) |

C° (F°) |

| Shipping Weight (Sys2) |

17.2 (38) |

kg (lb) |

| Unit Weight |

12.7 (28) |

kg (lb) |

| Dimensions |

Rack 483 x 400 x 133 (19 x 15.7 x 5.3)

Bench 436 x 398 x 129 (17.2 x 15.7 x 5.1) |

WxDxH

mm (in) |

| WATER COOLING (Sys2) |

|

|

|

| Flow |

1.5 (0.4) |

2.8 (0.75) |

l/m (g/m) |

| Max Input Pressure |

5.6 (80) |

Bar (lb/in2) |

| Pressure Differential |

2.8 - 5.5 (40-80) |

Bar (lb/in2) |

| Max Water Temp |

35 (95) |

C° (F°) |

1) Factory set 2) System includes workhead

Two Application Specific Work Heads

| LEFT |

RIGHT |

UNITS |

| 10 x 267 x 102 (4 x 10.5 x 4) |

102 x 204 x 102 (4 x 8 x 4) |

mm (in) |

| 4 (8.8) |

3 (6.6) |

kg (lb) |