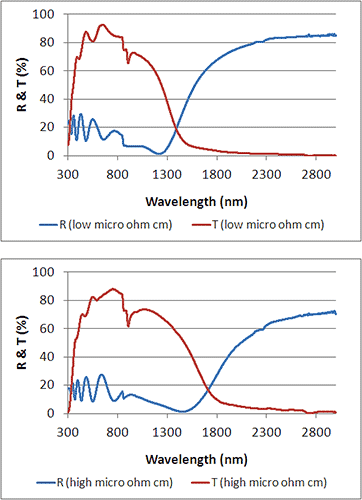

The transparent conductive oxides (TCOs) from Omega Optical offer a blend of infrared reflectance, electrical conductivity, and visible transmission. The figures below display two examples of indium tin oxide (ITO).

These coatings were produced by the R&D department’s aim to create transparent electrodes with specific operations that were not available in the market during work on a thin-film photovoltaic project.

Omega Optical has created several variants, including zinc tin oxide (ZTO), indium tin oxide (ITO), fluorinated zinc oxide (FZO), and indium zinc oxide (IZO), and has been constantly adding to this list.

By selecting the right material, the reflection edge and electrical properties of the film can be adjusted to fulfill customers’ requirements. TCO development also resulted in the addition of a broad-band hot mirror that blocks all the way into the IR.

In the figure above, the top image depicts the optical properties of highly conductive ITO, and the bottom image illustrates the properties of less conductive ITO. The electronic work function and the R&T curves differ when there is a change in the alloy composition.

Omega Optical deposits TCOs by carrying out co-sputtering of the constituent materials. Examples include indium oxide with tin oxide and zinc oxide with zinc fluoride.

- Custom sizes are available

- Specified thickness

Applications for Transparent Conductive Oxides

- Photovoltaics

- Displays

- RF shielding

- SERs substrates

- Heated windows

- Electrostatic control