The Evactron® Model 25 Zephyr is a plasma cleaner designed for in-situ cleaning of chambers and samples in vacuum chambers and electron microscopes.

The Evactron® plasma cleaner includes a dual-vacuum mode that enables TMP or roughing pump operation for microscopes with either diffusion-pumped or turbo-pump vacuum systems.

For all cleaning requirements, the Evactron® Model 25 Zephyr features a solid-state Micropirani Gauge. A table-top controller/RF generator with automatic RF/pressure level control, an RF Plasma Hollow Cathode Radical Source (PRS), a manual, cables and a limited warranty of five years.

System Features

- Completely adjustable ignition and operating pressures

- Dual-action cleaning using UV afterglow and plasma

- Pirani gauge for tracking chamber vacuum

- Turns on during pump down, which is safe for diffusion and turbo-pump operations

- Does not cause damage to sensitive components—no sputter etch

- Small desktop controller with a simple onebutton operation

- Complies to SEMI, NRTL, CE and TUV standards

- Programmable power, number of cycles and cleaning time

- Limited warranty of five years

- Room air is used as a gas source for low operating cost and ease of use

Specifications of Evactron® Model 25 Zephyr System

- RF generator is harmonically suppressed and stabilized

- RF power ranges between 10 to 20 W at 13.56 MHz

- Uses room air for the production of oxygen radicals

- Includes a KF 40 vacuum mounting flange

- Comes with a vacuum safety interlock

- Fixed RF Match fitted on an RF feedthrough

- MKS MicroPirani transducer enables vacuum measurement

- Serial interface, fault display, readout and log

- Servo-controlled air bleed valve for pressure and flow adjustments

- LEDs: Power on, Plasma on, RF on, enable switch and Fault; LCD is available for line display

- Electronic chassis—height × width× depth: 5.5″ × 9.5″ × 9.5″ (14 × 24.1 × 24.1 cm)

- Includes 100 to 240 VAC, 50/60 Hz input and 150 W

Image Credit: Evactron (XEI Scientific)

Image Credit: Evactron (XEI Scientific)

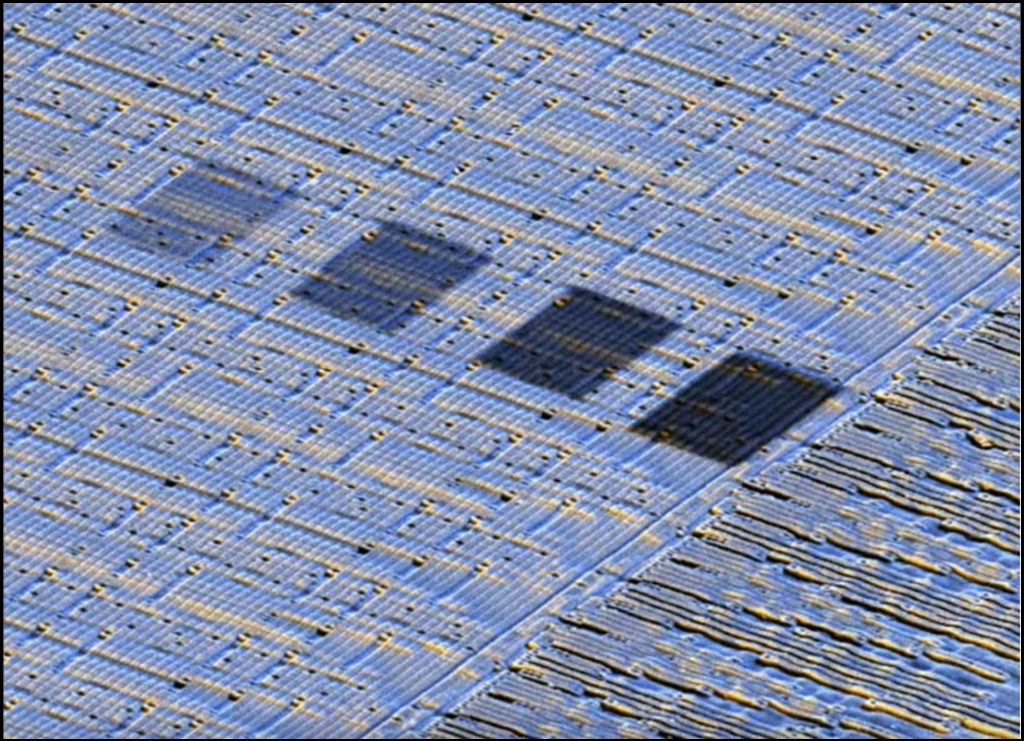

A nanoflight® movie of hydrocarbon removal was made in a Tescan MIRA3 SEM equipped with an Evactron® plasma cleaner. The movie sequence shows the removal of deposited hydrocarbon layers on a silicon wafer, four fields with different thicknesses, made by growing the layers for 1 / 2 / 4 / 8 hours at 2kV. Typically, vacuum chambers can be cleaned with the Turbo Plasma™ Cleaning process at turbo molecular pressures of 10-2 to 10-3 Torr with cleaning times of 2 - 10 minutes to maintain pristine conditions. Vacuum levels return to normal operating pressures in < 20 minutes.

Image Credit: Evactron (XEI Scientific)