The RH95 Relative Humidity Controller from Linkam Scientific has been developed to allow environmental sample control over Linkam’s array of temperature stages. It offers accurate control in a self-contained, compact package without the need for an external dry air supply.

The RH95 Relative Humidity Controller makes it feasible to integrate temperature control with relative humidity control within a stage. Humidity can have a considerable impact on material properties; these comprise cosmetic surface effects to variations in the mechanical properties of a sample, and also chemical changes, like producing polymorphs.

The RH95 Relative Humidity Controller has a wide range of applications, such as testing and characterization of new photovoltaic materials, the characterization of pharmaceuticals and research into new battery technologies.

The RH95 Relative Humidity Controller has been designed for use with Linkam’s MFS, THMS600, LTS420 and HFS600 stages, but it can also be utilized with all other sealed chambers with a volume of up to 2000cc between 5% and 90%.

In contrast to other humidity systems, expensive dry air supply is not needed.

Ambient air is dried via a uniquely developed automatic recycling desiccant system. The system can also be left to regulate humidity for several months at a time. Besides tracking the humidity of the air delivered to the chamber, a sensor has also been positioned within the chamber to generate a feedback loop to the controller.

For applications, where oxidation poses a problem, the RH95 Relative Humidity Controller can be delivered with the optional Inert Gas Regulator that helps use nitrogen as the carrier gas.

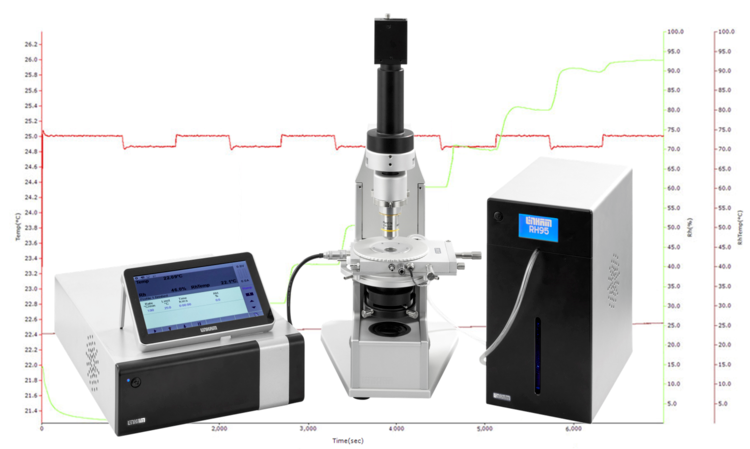

RH95 with THMS600-H and Imaging Station, T96 and Linkpad. Image Credit: Linkam Scientific Instruments

Features

- Relative humidity can be entered through a touch-screen display

- Can be utilized as an independent humidity generator and controller, or with LINK software to log data from the sensor

- Comes with a sensor regeneration module

- Long cycle times—can be left running for several months

- Highest controllable volume is 2000 cc

- Sensor validation chamber is provided with a salt ampoule testing kit

- Comes with an inert Gas Regulator (maximum input is 5 bar) module for nitrogen carrier gas

- Specifications

- Sensor type: Integrated temperature and humidity digital capacitance sensor

- Ramp speed is around 7% RH/minute

- Sensor response is around 8 seconds

- Stability at control value is +/–0.5%

- Recommended range is 5% to 90% RH