The most thermally conductive bulk substance is high-purity synthetic diamond. CVD diamond adds a new level to thermal control in electronics, prolonging device lifetime, lowering device footprint, and improving efficiency and effectiveness. This is especially important for the semiconductor manufacturing process where this enables innovations for technologies like 5G, electric vehicles, the Internet of Things, artificial intelligence, and defence and security applications.

CVD diamond translates a competitive advantage in electronic thermal control where power, temperature, and reliability are essential factors.

Increase Performance, Efficiency, and Device Lifetime

- By utilizing synthetic diamond’s unparalleled thermal performance, semiconductor design engineers can discuss today’s significant challenges, like increased reliability and increasing energy density on a smaller footprint, providing both device and system manufacturers with a world-leading competitive edge.

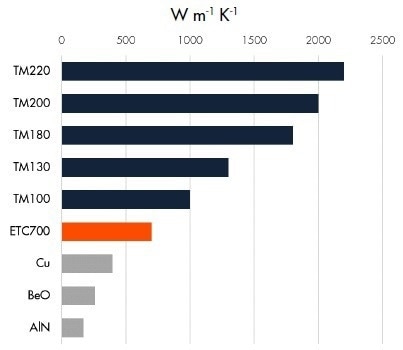

- CVD diamond is the ideal heat spreader for device and package designers as it combines low weight, electrical insulation, mechanical strength, low toxicity, and low dielectric constant with a room-temperature thermal conductivity that is up to five times greater than copper.

- Element Six develops diamond characteristics to match its clients’ unique performance/cost needs and customized cuts, metalizing diamonds to help customers integrate singulated heat spreaders into their modules and systems.

- CVD diamond enables dramatic increases in lifespan and power for the latest semiconductor GaN devices while lowering operational costs.

Transforming Thermal Management Performance

Highest Room-Temperature Thermal Conductivity of Any Material

Heat is the single most common cause of electronic failure. Theoretically, lowering the operating junction temperature by 10° C can quadruple the life of a gadget. CVD diamond beats today’s standard thermal management materials, like copper, silicon carbide, and aluminum nitride, by orders of magnitude.

Image Credit: Element Six

Element Six’s CVD Diamond Expertise Enables Smooth Customer Implementation

CVD diamond is available in thicknesses ranging from 250 to 1000 microns and diameters up to 140 mm. The laser cutting and polishing abilities of Element Six give clients the geometry, surface flatness, and minimal hardness that they need. The company's metallization expertise provides customers with a functional material for die bonding that has low thermal barrier resistances.

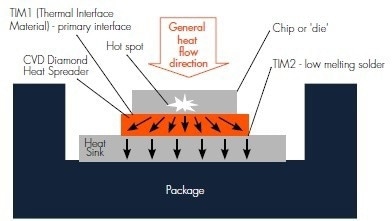

Typical Package Geometry with CVD Diamond Mounted Module

Image Credit: Element Six

Typical Applications

High-Power RF devices

- Base station RF amplifiers

- Microwave amplifiers

- Satellite RF uplink amplifiers

High-Power Optoelectronics

- High-brightness LEDs

- Optical planar IC modules

- Laser diodes and laser diode arrays

High Voltage Power Devices

- Energy distribution

- Automotive sub systems

- DC/DC converters

- Aerospace sub systems

Semiconductor Equipment

- Die-attachment processes

- Characterization testing

Rapidly Emerging Technology Applications

High-Power RF and Optoelectronics

Higher Power at Lower Operating Temperature

High-power RF and optoelectronic devices can use CVD diamond for the following reasons:

- Wide optical transmission allows CVD diamond heat spreaders to function within an optical path, like in laser cavities, without optical performance degradation.

- Run at the same power level but much cooler, thereby enhancing lifetimes and dependability.

- Run at complex power levels without collective junction operating temperature

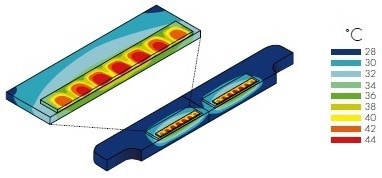

CVD Diamond Heat Spreader in RF Package

Image Credit: Element Six

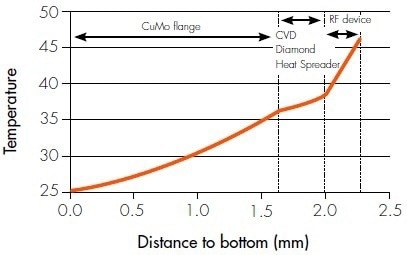

Temperature Drop Across RF Device Using CVD Diamond Heat Spreaders

Image Credit: Element Six

High-Voltage Power Devices

Smaller, Faster, High-Voltage Power Systems

CVD diamond delivers:

- Lowered system weight and footprint

- Reduction or elimination of auxiliary cooling systems

- Better consistency and improved efficiency by dropping device operating temperature

Semiconductor Assembly and Test

Longer Testing Time and Evenly Attached Die

By keeping device temperatures low, CVD diamond allows extensive stress testing and characterization of semiconductors. During die attachment, CVD diamond also guarantees that heat is swiftly and uniformly distributed across the whole semiconductor surface, resulting in strong and dependable contact.

Electrically Conductive CVD Diamond

DiafilmTM ETC700 combines the diamond’s superior heat dissipation with reduced resistive and RF losses, allowing smaller and more dependable high-power devices without compromising electronic properties.

Compound Semiconductor Devices

The efficiency of modern devices based on GaN, SiC, InP, and GaAS can be improved and their lifespan prolonged by using DiafilmTM series heat spreaders.

Collaboration in Applications Development

The expert team of application engineers and processing specialists work alongside its clients to build the best component for the application. The eventual efficiency of a component can be accurately predicted using the most recent computer modeling technology.

Advantages of CVD diamond

- A variety of thicknesses across large areas available

- Broad range of diamond bonding solutions

- Highest room temperature thermal conductivity of any material

- Chemical inertness and low toxicity

- Low roughness with high flatness possible

- Great mechanical power

- Electrically insulating

- Very low weight