The multi X 2500-for the Environmental Monitoring Needs from Analytik Jena is an all-rounder for Environmental Monitoring.

Benefits

- Versatile applications encompassing AOX, EOX, POX, TX/TOX, and TOC sum parameters

- Incorporates both vertical and horizontal sample feeding within a single system

- Maintains cost-effective operations with minimal maintenance requirements

- Achieves high sample throughput while ensuring precise measurements

The Multi X 2500 demonstrates its versatility in sum parameter analysis, making it suitable for a wide range of applications. It can be utilized for monitoring AOX/TOX, EOX, and POX in wastewater, sludge, and soil, as well as for crucial TOC analysis in wastewater.

It excels in determining TX/TOX contents within complex organic matrices. Its user-friendly operation, exceptional application adaptability, and automation features contribute to the generation of dependable results and the highest possible sample throughput, all achieved with minimal effort.

Optimal Adjustment for Each Sample Matrix

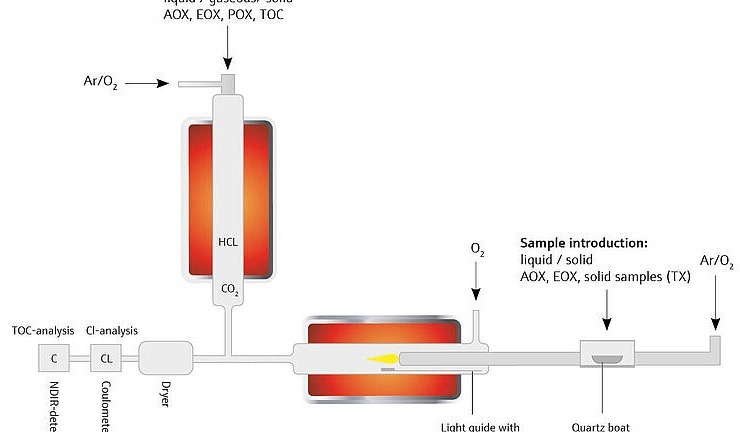

The innovative dual-furnace technology featuring a tilting furnace seamlessly integrates the benefits of both vertical and horizontal sample feeding and combustion into a single analysis system. This design establishes new industry standards.

Features

- User-friendly operation

- Plug-and-play technology for quick setup

- Substantially decreased maintenance requirements

- Dual furnace for optimal sample matrix adaptation

- Efficient sample throughput in both vertical and horizontal modes

- High-efficiency sample preparation systems with Speed Load for continuous 24/7 operation

- Patented wide-range coulometer with a cooled titration cell for stable, comfortable analysis

- Matrix-optimized quantitative combustion using the Flame Sensor, even for unknown samples

Image Credit: Analytik Jena US

Image Credit: Analytik Jena US

Environmental Analysis Made Easy

Throughout environmental monitoring, process control, and quality assessment, the measurement of organically bound halogens, particularly those adsorbed on activated carbon, plays a pivotal role in appraising water and wastewater quality.

With the multi X 2500, Analytik Jena introduces a versatile, forward-looking system for halogen sum parameter analysis, catering to the diverse needs of every laboratory. This solution addresses the ongoing challenges of rising costs and an expanding number of samples.

Conceived as an exceptionally efficient and low-maintenance AOX analyzer with remarkably economical operational costs, the multi X 2500 ensures reliability, adaptability, precision, and unparalleled ease of use.

Its advantages include straightforward operation, swift readiness, and minimal maintenance demands. The intelligent multiWin software, the fast changeover between column and batch methods, and the user-friendly design ensure outstanding ease of use and efficiency.

Image Credit: Analytik Jena US

Sophisticated automatic sampling systems, when combined with the versatile sample preparation systems of the APU and AFU series, enable both fully and partially automated AOX analysis. These perfectly synchronized systems streamline sample preparation and analysis, offering flexibility and cost-efficiency. They significantly reduce idle time and increase the throughput of AOX samples.

The innovative double furnace technology, featuring a tilting furnace, incorporates the benefits of both vertical and horizontal combustion in a single analysis system, setting new standards in design.

This technology facilitates ultra-fast AOX routine analysis in the vertical mode and reliable detection of the smallest EOX traces in the horizontal mode, allowing users to select the most appropriate combustion mode for their application.

AOX analysis and sample preparation systems

Video Credit: Analytik Jena US

Mare SpA – Determination of AOX in water with Analytik Jena's multi X 2500 (IT, EN subtitles)

Video Credit: Analytik Jena US

Applications

Chemicals and Materials

- Quantifying total chlorine and organically bound chlorine in pulp, paper, and secondary pulp in compliance with ISO 11480 using an AOX analyzer

- Measuring total chlorine and organically bound chlorine in pulp, paper, and secondary pulp in accordance with ISO 11480 using an AOX analyzer

- AOX analysis of wastewater samples via column method as per DIN EN ISO 9562

- Determination of AOX in wastewater samples using the column method according to DIN EN ISO 9562 (DE)

Environment

- Linearity assessment in accordance with DIN EN ISO 9562 (Column Method)

- Measuring adsorbable organic halogens in highly saline water samples after solid phase extraction

- Determining EOX in waste and soil samples following DIN 38414-17 and EPA 9023

- Sample preparation for AOF determination in water, as per E DIN 38409-59

- Quantification of AOX in groundwater, raw water, drinking water, and surface water, following DIN EN ISO 9562

- AOX analysis of sewage sludge samples using the batch method as per EN 16166

- AOX assessment in sewage sludge samples using the shake method, compliant with EN 16166

- Total halogens determination in used oil

- Quantifying total chlorine and organically bound chlorine in pulp, paper, and secondary pulp as per ISO 11480 with an AOX analyzer

- Quantifying total chlorine and organically bound chlorine in pulp, paper, and secondary pulp as per ISO 11480 with an AOX analyzer

- AOX analysis of wastewater samples via column method, according to DIN EN ISO 9562

- Chlorine determination in used oil

- AOX measurement in wastewater samples via column method, according to DIN EN ISO 9562

- Measuring adsorbable organically bound halogens in highly saline water samples after solid-phase extraction

- Determination of total halogens in used oil

- EOX measurement in waste and soil samples, according to DIN 38414-17 and EPA 9023

- Linearity test for AOX measurement in accordance with DIN EN ISO 9562 (column method)

- Sample preparation for AOF determination in water samples as per E DIN 38409-59

- Quantification of AOX in raw, drinking, and groundwater, as well as in surface water, following ISO 9562

Oil and Gas

- Quantification of AOX in wastewater samples via column method as per DIN EN ISO 9562

- Detection of AOX in wastewater samples using the column method according to DIN EN ISO 9562

Technical Data

Source: Analytik Jena US

| |

Min. measurement time |

Precision |

Injection Volume |

Detector |

Sample Supply |

method |

multi X 2500

450-126.430 |

8 min |

at > 5 µg Cl, RSD better 2% at >10 mg/L TOC, RSD better 2% % |

1 - 100 µL |

Cl: coulometric titration C: NDIR |

vertical and horizontal, manual or automated (accessories required) |

AOX acc. batch method, AOX acc. column method |

Optimal Adaptation to Any Sample Matrix

Plug-and-Play

Upon initialization, the multi X 2500 autonomously conducts comprehensive testing of all components and functions. In the case of installed sampling systems, it identifies the active configuration and seamlessly integrates it into the multiWin software configuration, with the multi X 2500 making automatic adjustments to all settings.

Double Furnace Technology

The double furnace technology allows swift transitions between vertical and horizontal applications within a single instrument. This ensures rapid and precise adaptation for each sample matrix and analytical standard. The double furnace technology, a vital element for uniquely flexible operation, comes as standard equipment with each multi X 2500.

Image Credit: Analytik Jena US

Advantages of the Vertical Sample Feed

- Ideal for AOX analysis using the batch and column method

- Optimal for the AOX direct feed of enriched activated carbon without column (high throughput operation)

- Fast analysis at small footprint

- Also suited for EOX, POX, and TOC determination

Advantages of the Horizontal Sample Feed

- Ideal for precise EOX measurements in extracts rich in resinous components

- Appropriate for both column and batch AOX determinations

- Features a combustion process optimized for time and sample matrix

- Suitable for chlorine analysis in solid and liquid samples, such as derived fuels and used oil

- Incorporates flame sensor technology to prevent soot formation in challenging samples

Self Check System (SCS)

To ensure trouble-free and fully automated operation, each multi X 2500 is equipped with the SCS. This system consistently monitors and adjusts all parameters critical for the instrument's safety and the quality of analyses. The outcome is remarkable performance and flawless measurement results.

- Ensures operational safety with minimal user intervention

- Ideal for round-the-clock operations in contract analysis

- Identifies and prepares all modules automatically, saving valuable time

- Monitoring of maintenance intervals

- Automatic system shutdown in case of system failure

Flame Sensor

Whether you choose AOX, EOX, or POX measurement methods, the maintenance-free, integrated gasbox ensures the highest level of operational safety and dependable analysis results.

It maintains a stable gas flow for complete combustion, automatically regulated by the system. The built-in electronic flow sensor allows operators to easily check for leaks at any moment, eliminating the need for time-consuming, imprecise adjustments and constant visual inspections.

Auto-Protection

Auto-Protection prevents system damage caused by particles, aerosols, and liquids. This feature includes efficient cleaning and drying of reaction gases, along with monitoring and protection functions that enhance analysis safety. It also minimizes maintenance efforts and extends the lifespan of components.

Integrated heating also prevents condensation losses and ensures ultra-low detection limits.

Flow Management System with High-Performance Gasbox

Whether users’ chosen the AOX, EOX, or POX measuring method, the maintenance-free integrated gasbox ensures the highest level of operational safety and dependable analysis results.

It assures a steady gas flow for thorough combustion, which the system automatically regulates. With the integrated electronic flow sensor, operators can promptly inspect the system for leaks whenever necessary. This eliminates the need for time-consuming and inaccurate adjustments and continuous visual monitoring.

Highly Sensitive Detection

A patented measuring cell in the system ensures accuracy in analyses, even at high concentrations, making overdosing impossible. The dynamic working range allows reliable analysis of samples with unexpectedly high AOX concentrations.

Designed for maximum sample throughput, the measuring cell and electrolyte are optimized for use with autosamplers. This allows the multi X 2500 to analyze large series of samples with varying concentrations without the need for any interventions, like an electrolyte change.

Thanks to the instrument's patented detection technology, labs can easily satisfy all AOX analysis needs. Its unique wide-range coulometer provides an extensive dynamic measuring range, facilitating adaptation to a diverse array of measuring tasks with unparalleled sensitivity.

Whether it is EOX detection at trace levels or high TX contents in alternative fuels, the wide-range coulometer fulfills all specifications.